| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 15V025

Manufacturer Mack Trucks , Inc.

, Inc.

Components PARKING BRAKE

Potential Number of Units Affected 349

Internal Rubber Diaphragm Incomplete Attachment

If the diaphragm is not completely attached, there may be internal leakage from the service section past the diaphragm, potentially trapping air pressure in the parking brake section. This air pressure in turn, if not vented, may prevent full release of the actuator unit, and may induce brake drag and may result in overheated wheelend service brakes, increasing the risk of a fire.

Summary

Mack Trucks , Inc. (Mack

, Inc. (Mack ) is recalling certain model year 2015 and 2016 CXU and LEU trucks manufactured May 20, 2014, to March 24, 2015, equipped with certain Haldex

) is recalling certain model year 2015 and 2016 CXU and LEU trucks manufactured May 20, 2014, to March 24, 2015, equipped with certain Haldex Life Seal Type 30/30 Long Stroke Air Brake Actuators manufactured from January 9, 2014, through February 3, 2015. The affected actuators may have an incomplete attachment of the internal rubber diaphragm to the actuation mechanism of the parking brake section of the Life Seal actuator.

Life Seal Type 30/30 Long Stroke Air Brake Actuators manufactured from January 9, 2014, through February 3, 2015. The affected actuators may have an incomplete attachment of the internal rubber diaphragm to the actuation mechanism of the parking brake section of the Life Seal actuator.

Remedy

Mack will notify owners, and dealers will inspect the brake actuator and replace, as necessary, free of charge. The recall began March 20, 2015. Owners may contact Mack

will notify owners, and dealers will inspect the brake actuator and replace, as necessary, free of charge. The recall began March 20, 2015. Owners may contact Mack customer service at 1-610-709-2131. Mack

customer service at 1-610-709-2131. Mack ’s number for this recall is SC0387.

’s number for this recall is SC0387.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

SAFETY RECALL ALERT

| To: | U.S. and Canada Distributors Dealer Principals Service Managers Warranty Managers Parts Managers | Bulletin: | SRA-M-0387 |

|---|---|---|---|

| Date: | January 26, 2015 | ||

| Action Required? | YES | ||

| From: | Regulatory Affairs Department | ||

| Subject: | Safety Recall, SC0387, Haldex Life Seal brand 30/30 long stroke brake actuator Life Seal brand 30/30 long stroke brake actuator | ||

Summary:

Description of Defect:

According to Haldex , “during the assembly of the Life Seal actuator unit, the internal rubber diaphragm may not be fully seated in the spring piston of the parking brake section, thereby causing internal leakage from the service section past the diaphragm and potentially trapping air pressure in the parking brake section. This air pressure in turn, if not vented, may prevent full release of the actuator unit, and may induce dragging and overheated wheel end foundation service brakes.”

, “during the assembly of the Life Seal actuator unit, the internal rubber diaphragm may not be fully seated in the spring piston of the parking brake section, thereby causing internal leakage from the service section past the diaphragm and potentially trapping air pressure in the parking brake section. This air pressure in turn, if not vented, may prevent full release of the actuator unit, and may induce dragging and overheated wheel end foundation service brakes.”

The potential risk is for overheating at the wheel end, which increasing the risk of fire.

Models/ Model Years Affected:

Mack : 2015 CXU model trucks manufactured from May 20, 2014 through November 12, 2014 with a Haldex

: 2015 CXU model trucks manufactured from May 20, 2014 through November 12, 2014 with a Haldex Life Seal brand 30/30 long stroke brake actuator.

Life Seal brand 30/30 long stroke brake actuator.

Vehicle Quantities:

Mack : 276 in total (274 U.S., 2 Canada).

: 276 in total (274 U.S., 2 Canada).

Dealer’s Responsibility:

The National Traffic and Motor Vehicle Safety Act and Canadian Motor Vehicle Safety Act requires dealers to ensure that all new and used vehicles are free of safety defects and comply with all relevant safety standards at the time of delivery to the consumer.

Dealers should make their personnel aware of the safety recall. In the event that a dealer has a vehicle included in the safety recall in their inventory to be sold, the condition must be corrected before releasing it to a customer.

Release Schedule:

- Vehicle will be posted on the Trucks Dealer Portal January 26, 2015.

- Repair Instructions are tentatively scheduled for release no later than March 19, 2015.

- Owner Notices are scheduled to be mailed on or before March 19, 2015.

Questions:

Contact the Regulatory Affairs Department at vtna.regulatoryaffairs@volvo .com if you have questions.

.com if you have questions.

SAFETY RECALL

| Date | Number | Release | Page |

| 03.2015 | SC0387 | 01 | 1 (13) |

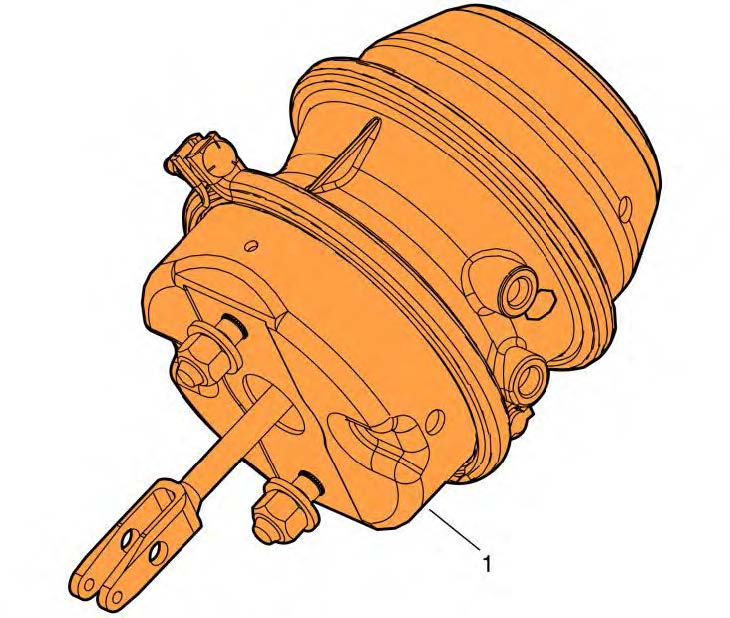

Brake Chamber

CXU

SAFETY RECALL INFORMATION:

(March 2015)

During the assembly of the Life Seal actuator unit in the Halidex brake chamber, the internal rubber diaphragm may not have been fully seated in the spring piston of the parking brake section. Improper seating of the rubber diaphragm may cause internal air leakage from the service section past the diaphragm and potentially trap air (buildup air pressure) in the parking brake section. If the trapped air is not vented, the buildup in air pressure may prevent full release of the actuator unit. Additionally, the trapped air may induce dragging, overheated wheel end foundation service brakes, and may increase the risk of fire.

MACK Trucks has received no reports of personal injury as a result of this condition. Therefore, Mack

has received no reports of personal injury as a result of this condition. Therefore, Mack considers this as a proactive measure to protect the public and MACK

considers this as a proactive measure to protect the public and MACK ’s customers from the potential risk associated with this defect.

’s customers from the potential risk associated with this defect.

VEHICLES AFFECTED:

Certain 2015 MACK CXU model trucks manufactured from May 20, 2014 through November 12, 2014, equipped with a Haldex

CXU model trucks manufactured from May 20, 2014 through November 12, 2014, equipped with a Haldex Life Seal brand 30/30 long stroke brake actuator.

Life Seal brand 30/30 long stroke brake actuator.

VEHICLE IDENTIFICATION NUMBERS (VIN):

The number of vehicles affected by this recall is 276 (274 USA, and 2 Canada).

Required Parts:

To schedule parts orders and repairs, please call (877) 986-5862 with the Vehicle Identification Number (VIN) of the vehicle in need of this repair. The parts for this repair will not be available until April 15, 2015.

| Item | PART NUMBER | QTY | DESCRIPTION |

|---|---|---|---|

| 1 | 85145824 | 2 Per Axle | Brake Chamber, Halidex |

Decommissioning the Truck for Inspection or Repair:

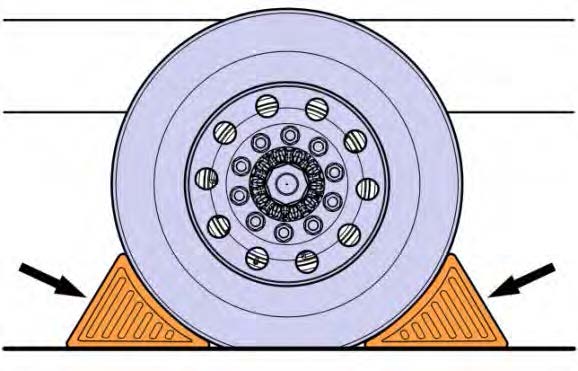

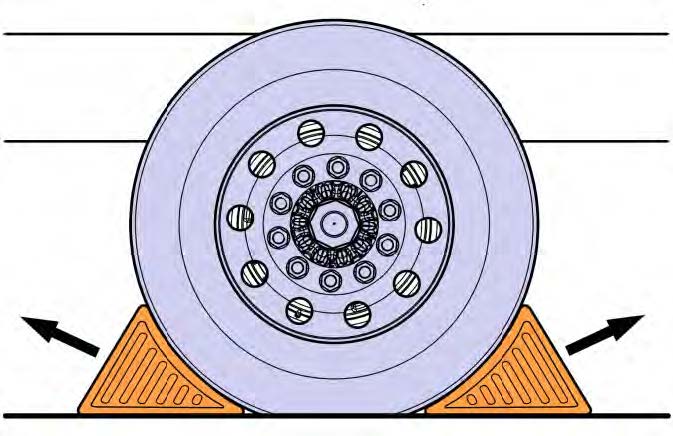

- Secure the vehicle for service by parking on a flat and level surface, placing the transmission in neutral, applying the parking brake, turning the ignition key to the OFF position, and chocking the front wheels.

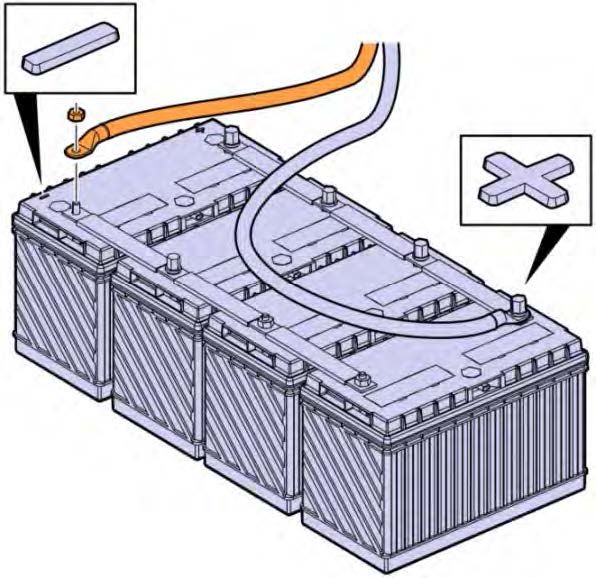

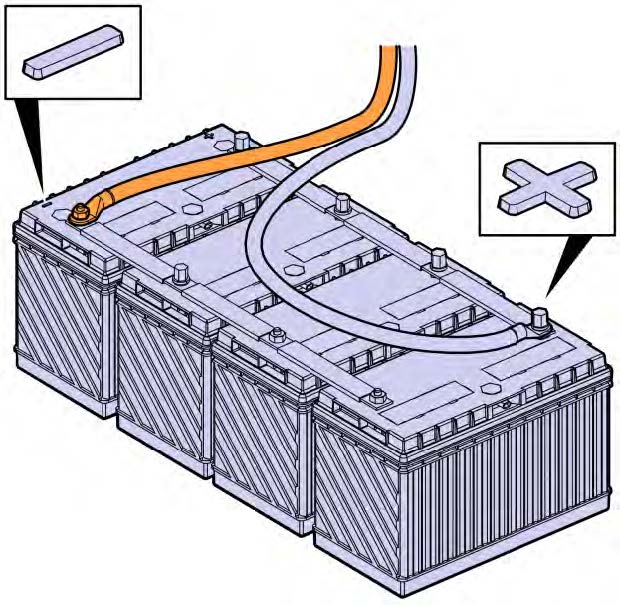

- Disconnect the cable from the battery’s negative (ground) terminal.

Brake Chamber Replacement Procedure:

| NOTE |

| The Illustrations shown in this document are used for reference only and may differ slightly from the actual vehicle being serviced. However, the replacement procedure represented as accurately as possible. |

| DANGER |

| Park brake chambers are under extreme pressure and safe work practices should be observed. If instructions are not followed correctly, personal injury or death will occur. |

- Drain the complete air system of all pressure.

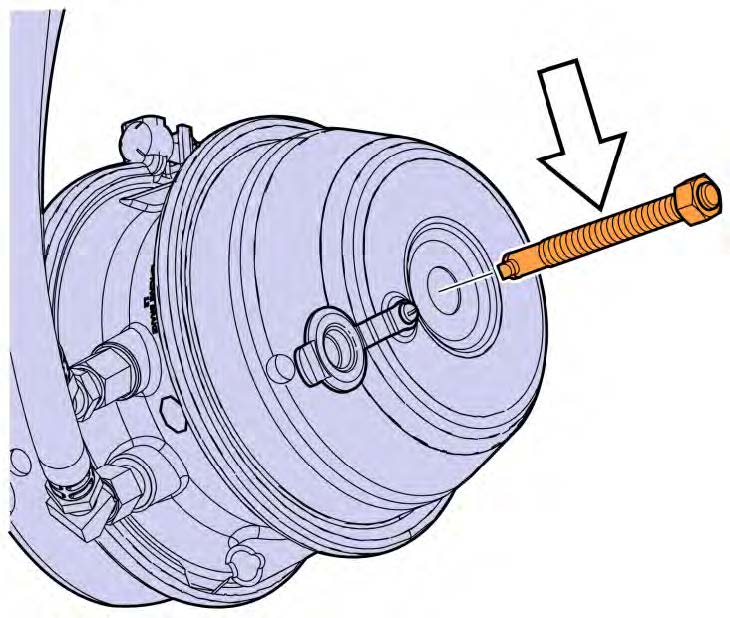

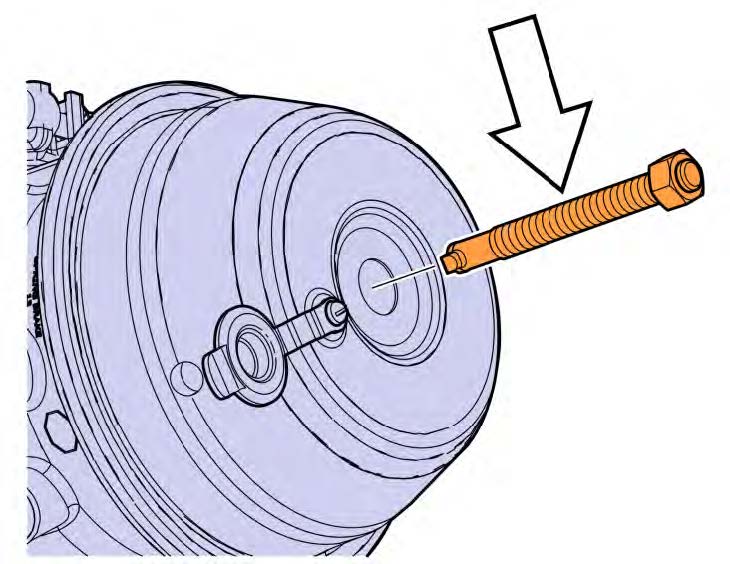

- Cage the brake chamber.

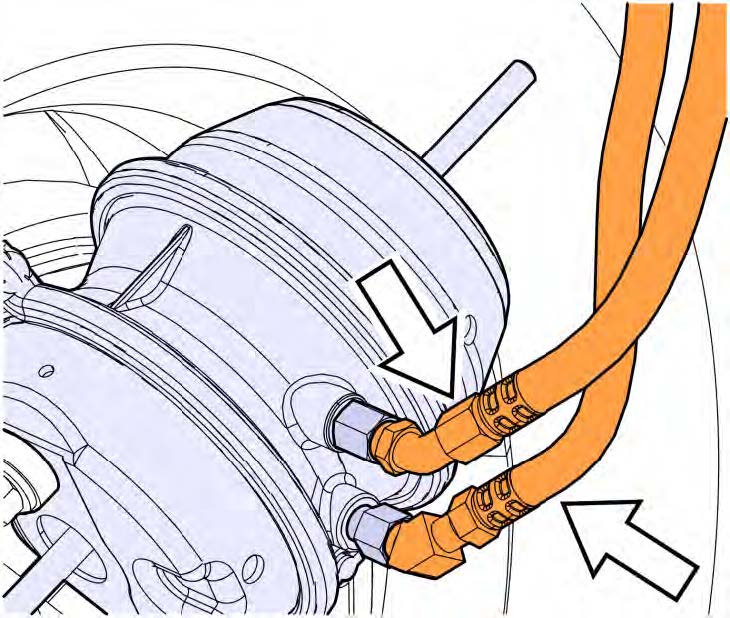

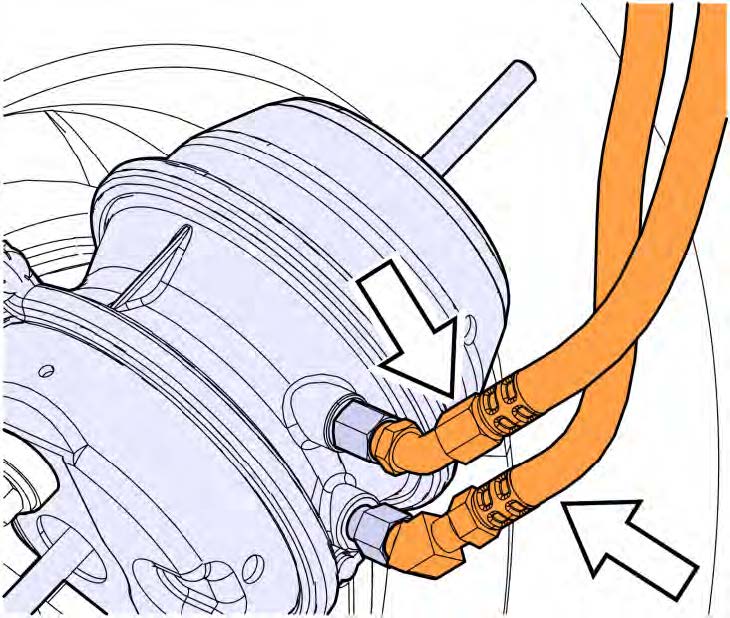

- Disconnect the park brake and service supply air lines from the park brake chamber.

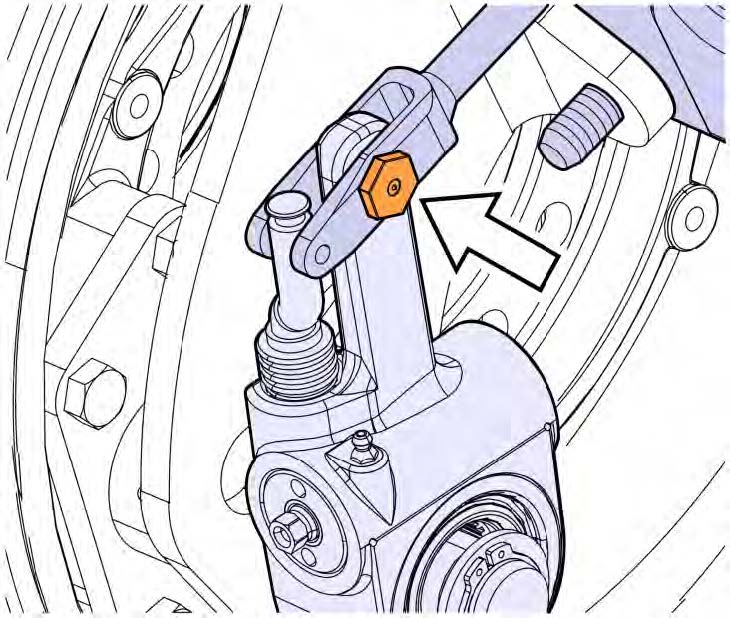

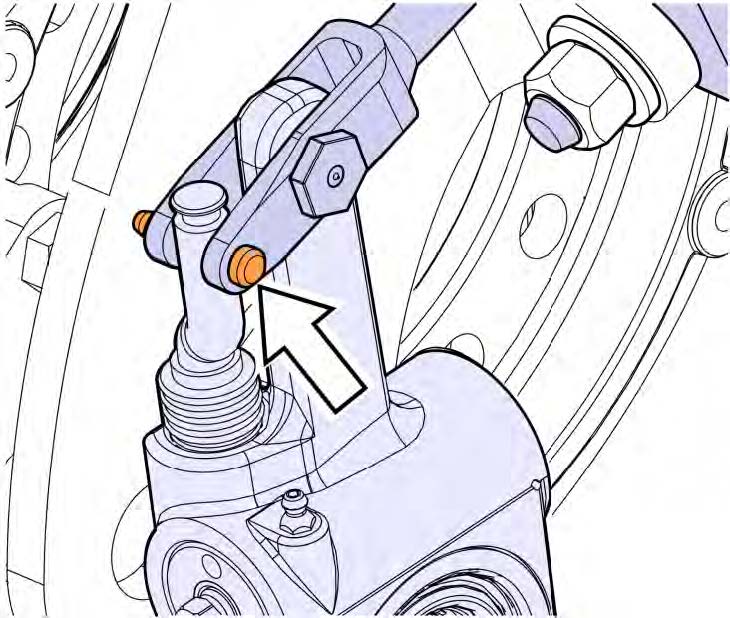

- If applicable, remove the cotter pin and clevis pin from the park brake chamber rod.

| NOTE |

| Do not discard the clevis pin. Clean and store for reuse. |

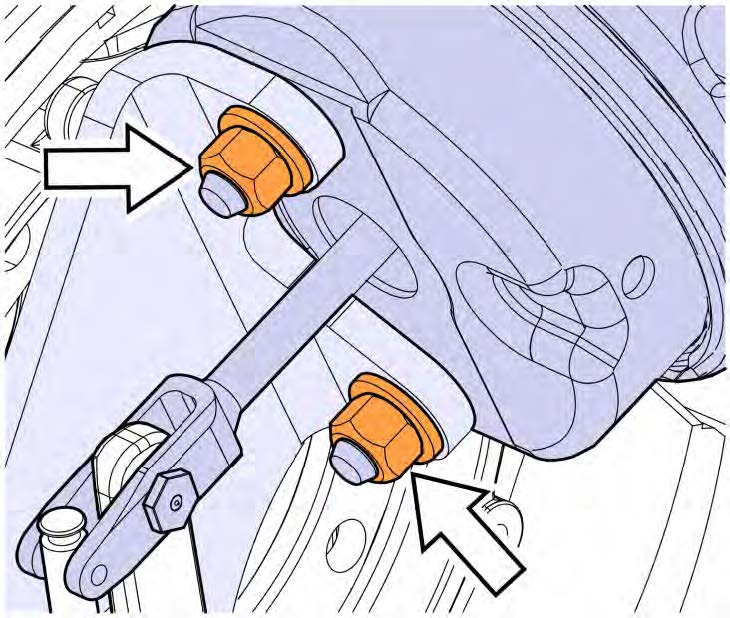

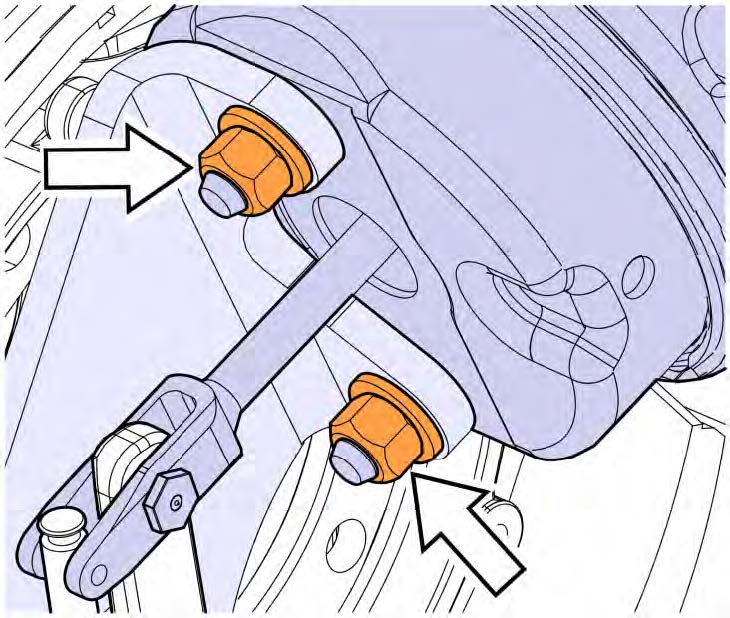

- Remove the two nuts and washers from the park brake studs.

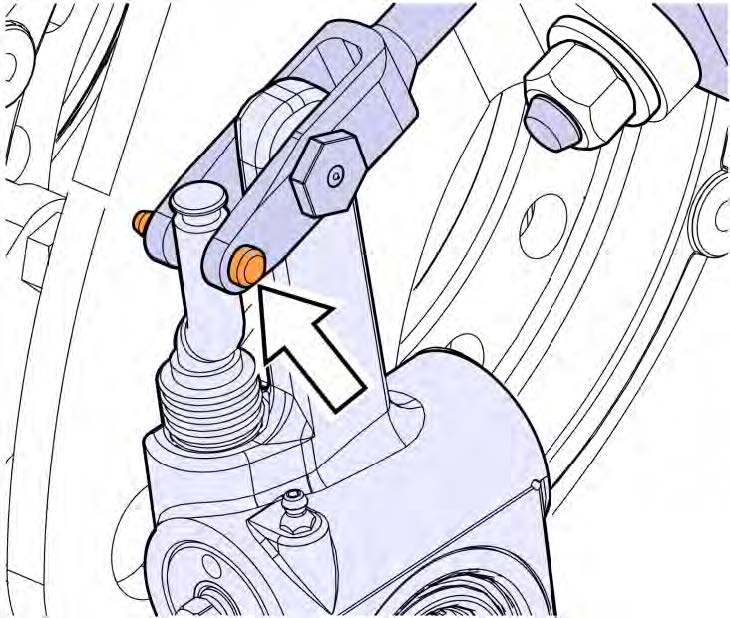

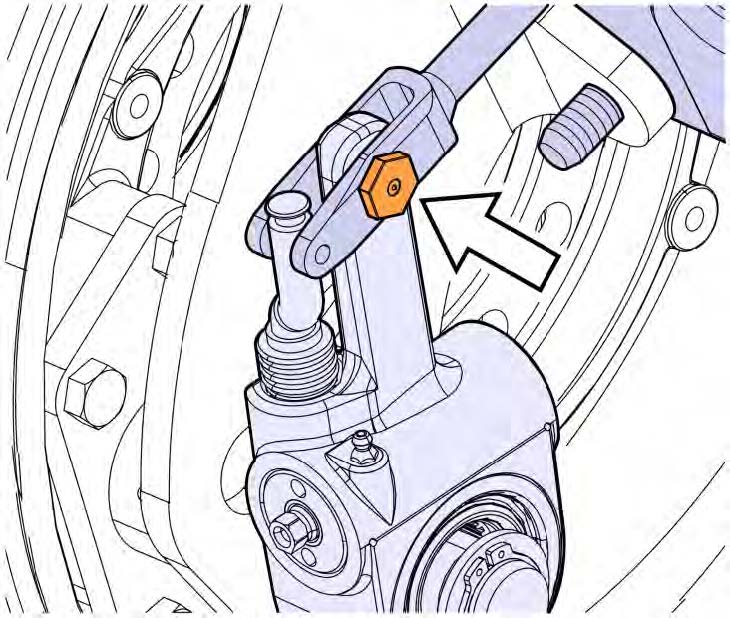

- Remove the cotter pin and clevis pin from the slack adjuster.

| NOTE |

| Do not discard the clevis pin. Clean and store for reuse. |

- Remove the existing park brake chamber.

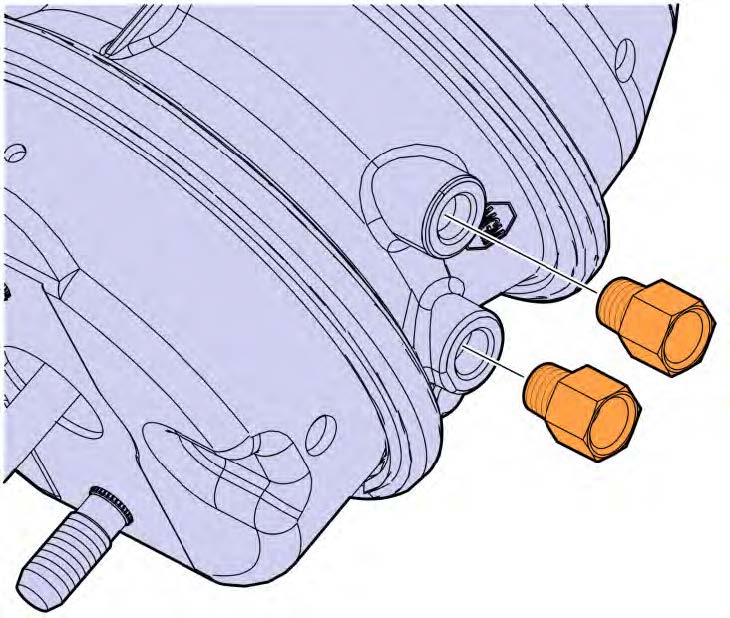

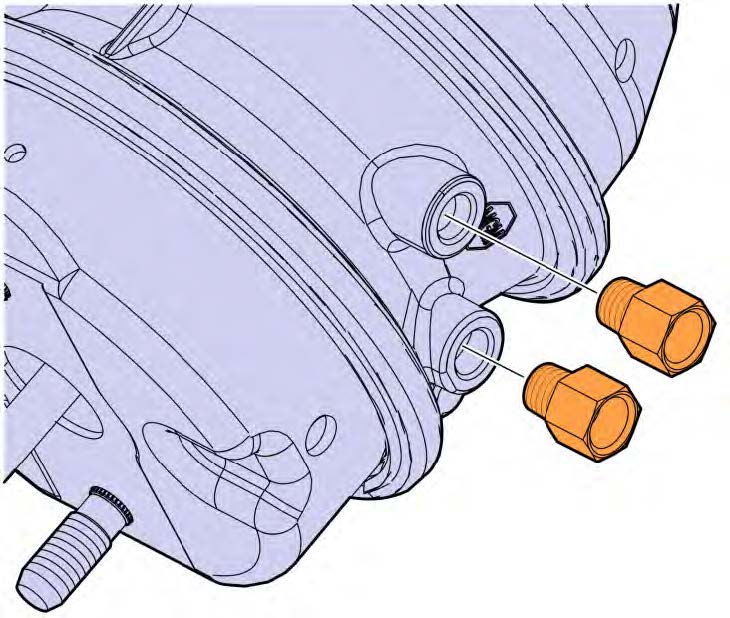

- Remove the fittings from the existing park brake chamber.

| NOTE |

| Clean the fittings of any debris and store them for reuse. |

- Using thread sealant, install the fittings on the replacement park brake chamber.

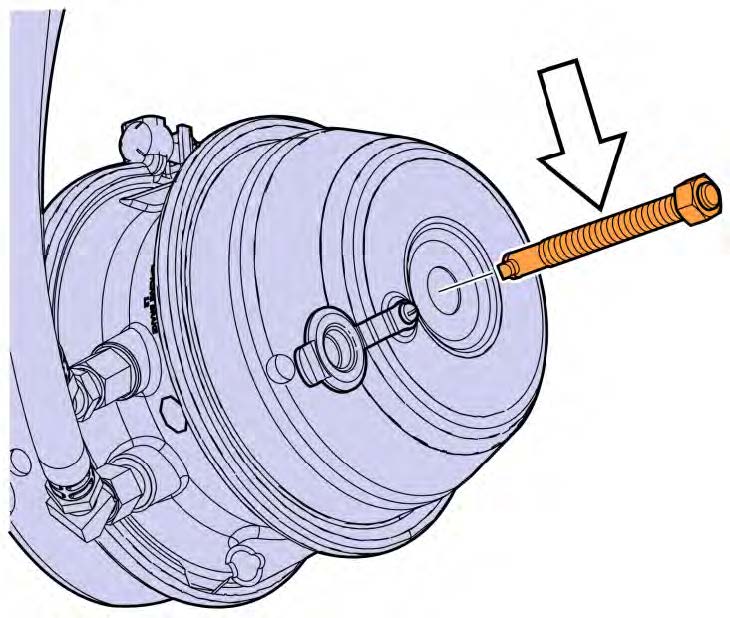

- Cage the replacement park brake chamber.

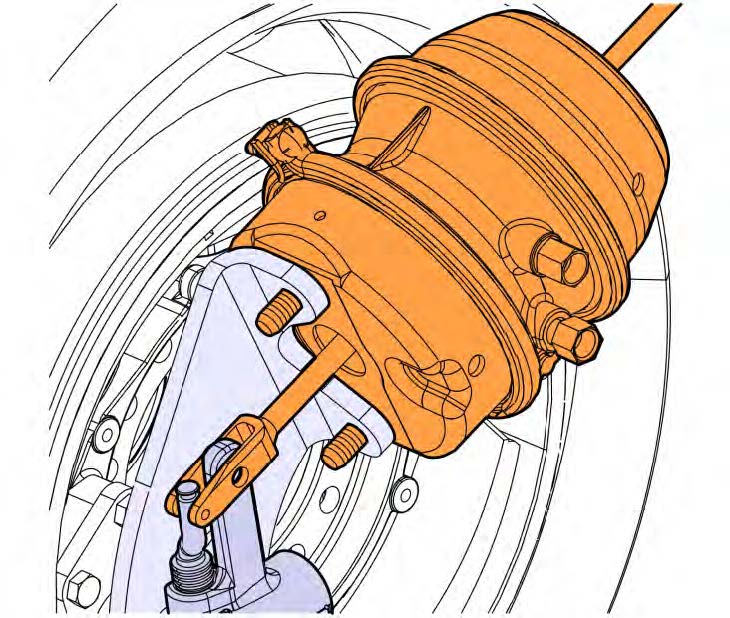

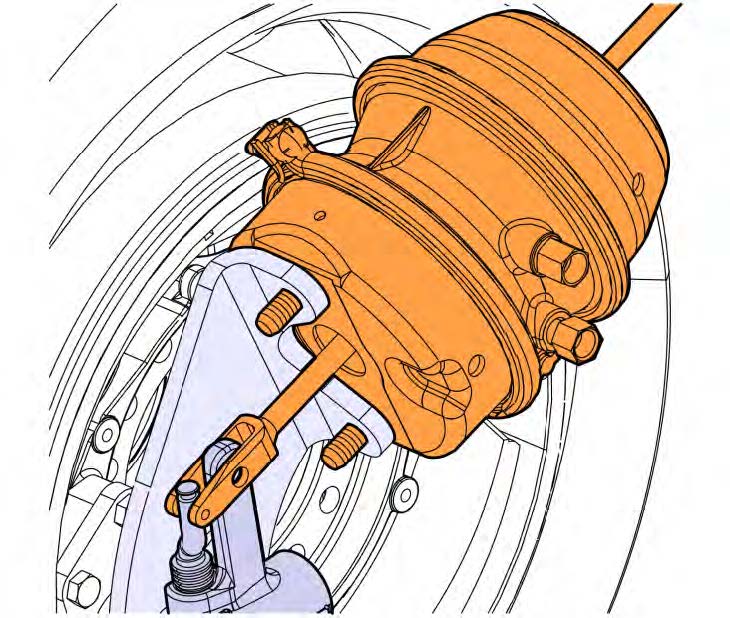

- Position the replacement park brake chamber as shown in the figure below.

- Install the clevis pin into the park brake chamber rod.

- Secure the clevis pin with a new cotter pin.

- Install the two nuts and washers on the parking brake chamber studs.

- Tighten the two nuts to 195 ± 15 Nm (144 ± 11ft-lb).

- If applicable, install the clevis pin and cotter pin into the slack adjuster.

- Secure the clevis pin with a new cotter pin.

- Connect the park brake and service supply air lines to the park brake chamber.

- Un-cage the replacement park brake chamber.

| NOTE |

| Ensure the brake chamber portal is covered with the supplied dust cover after the park brake chamber is un-caged. |

- Repeat steps 1 – 19 for the remaining wheel-end positions.

Commissioning the Truck for Operation:

- Connect the battery cable to the negative (ground) terminal.

- Start the engine, build the proper air system pressure, check for air leaks, and proper service/park brake operation.

- Remove the wheel chocks.

Reimbursement:

| This repair is covered by an authorized Safety Recall campaign. Reimbursement is obtained through the normal claim handling process. | ||

| UCHP Reimbursement | eWarranty Reimbursement | |

| Claim Type (Used when uploading from the Dealer business System) | 40 | 40 |

| Recall Status | ||

| Vehicle repaired per instructions | 1-Modified per instructions | |

| Labor Code | ||

| Primary Labor Code (Brake Chamber, Replacement, per axle, two brake chambers) | 5126-03-09-04 1.3 hrs | 5172D-ZP-95 1.3 hrs |

| Time to take charge of vehicle and determine campaign status | 1700-16-01-01 0.3 hrs | 101AA-0A-00 0.3 hrs |

| Causal Part | 85145824 | 85145824 |

| Authorization Number | C6554 | SC0387 |

Take-charge time is not included in the labor code for this operation. Take charge may be eligible, but can only be used once per vehicle repair visit. If the vehicle is having other warranty repairs performed, take-charge should be charged to the warranty repair, otherwise take-charge can be charged to this Safety Recall campaign.

IMPORTANT SAFETY RECALL SC0387

NHTSA RECALL # 15V-025

DEAR MACK TRUCK OWNER:

OWNER:

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Mack Trucks , Inc. has decided that a defect which relates to motor vehicle safety exists in certain 2015 CXU model vehicles manufactured with Haldex

, Inc. has decided that a defect which relates to motor vehicle safety exists in certain 2015 CXU model vehicles manufactured with Haldex Life Seal brand 30/30 long stroke brake actuator from May 20, 2014 through November 12, 2014.

Life Seal brand 30/30 long stroke brake actuator from May 20, 2014 through November 12, 2014.

| SAFETY DEFECT: | The internal rubber diaphragm may not be fully seated in the spring piston of the parking brake section, thereby causing internal leakage from the service section past the diaphragm and potentially trapping air pressure in the parking brake section. This air pressure in turn, if not vented, may prevent full release of the actuator unit, and may induce dragging and overheated wheel end foundation service brakes. |

| SAFETY RISK: | The potential risk is for overheating at the wheel end, and the possibility of fire. |

| PRECAUTIONS YOU CAN TAKE: | There are no precautions you can take other than having your vehicle inspected and repaired if needed by a Mack Parts and Service Center. Parts and Service Center. |

| TIME REQUIRED FOR THE REPAIR: | The time required to repair your vehicle is approximately 2-4.5 hours. |

| WHAT YOU SHOULD DO: | Parts will be available on April 15th. On April 15th, you should contact the nearest Mack Parts and Service Center and make an appointment. Your vehicle will be repaired at no charge to you. Parts and Service Center and make an appointment. Your vehicle will be repaired at no charge to you.

You can locate the closest Mack |

| NOTICE REGARDING LEASED VEHICLES: | If you are a Lessor of vehicles subject to this Notice, you have an obligation under Federal Law to provide a copy of this Notice to all Lessees within 10 days of your receipt of this Notice. Further, you must maintain a record, which identifies the Lessee(s) to whom you send a copy of this letter, the date you send this letter, and the Vehicle Identification Number(s) of the vehicle(s) that you have leased to that lessee. For purposes of this Notice, the term Lessor means: a person or entity that is the owner, as reflected on the vehicle’s title, of any five or more leased vehicles (as defined in CFR Section 577.4), as of the date of notification by the manufacturer of the existence of a safety-related defect or non-compliance with a Federal Motor Vehicle Safety Standard in one or more of the leased motor vehicles. |

| OWNER RECALL RESPONSE CARD: | The enclosed “Notice of Vehicle Recall” identifies your vehicle. If you no longer own the vehicle, please help us update our records by completing the “Vehicle Disposition Record” portion of the enclosed postage-free Notice of Mandatory Safety Campaign card and mailing it back to us. |

| ASSISTANCE/

COMPLAINTS: | If your vehicle has not been repaired within a reasonable time after delivering it to a Mack Parts and Service Center, please contact: Parts and Service Center, please contact:

Mack Trucks You may also submit complaints to the Administrator of the National Highway Traffic Safety Administration (1200 New Jersey Avenue, S.E., Washington DC 20590 or call the toll-free Auto Safety Hot Line at 1-888327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov if you believe that Mack |

| PRE NOTIFICATION REMEDIES: | If you have previously paid for repairs as a result of this issue, you may be entitled to recovery of those expenses.

Submit copies of all documentation supporting your claim according to the rules specified in the “General Plan for Reimbursement of Prenotification Remedies” provided in this mailing. |

We regret any inconvenience this may cause to your operation, but hope you will appreciate our sincere efforts to demonstrate Mack ’s commitment to provide our customers with the best possible product.

’s commitment to provide our customers with the best possible product.

MACK TRUCKS , INC.

, INC.

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...

Loading...