| “This site contains affiliate links for which OEMDTC may be compensated” |

July 18, 2023 NHTSA CAMPAIGN NUMBER: 23E054000

An engine that detaches from the lifting bracket while being lifted increases the risk of injury.

NHTSA Campaign Number: 23E054

Manufacturer Cummins , Inc.

, Inc.

Components ENGINE AND ENGINE COOLING

Potential Number of Units Affected 59

Summary

Cummins , Inc. (Cummins

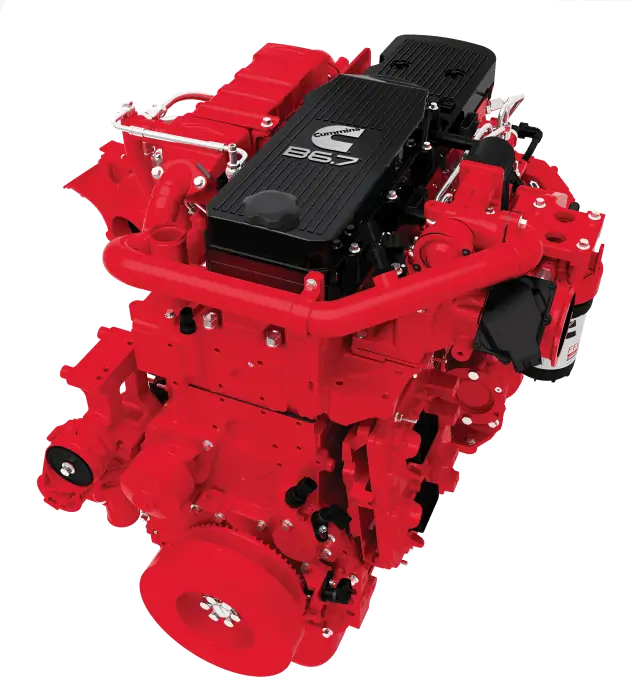

, Inc. (Cummins ) is recalling certain Model: B6.7 diesel engines, part number D313038BX03. An insufficiently tightened bolt can cause the rear lifting bracket to detach from the cylinder head.

) is recalling certain Model: B6.7 diesel engines, part number D313038BX03. An insufficiently tightened bolt can cause the rear lifting bracket to detach from the cylinder head.

Remedy

Dealers will inspect and replace the bracket, bolts, fuel lines, and cylinder heads as necessary, free of charge. Owner notification letters are expected to be mailed September 15, 2023. Owners may contact Cummins customer service at 1-800-286-6467. Cummins

customer service at 1-800-286-6467. Cummins number for this recall is C2716.

number for this recall is C2716.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.nhtsa.gov.

*** IMPORTANT SAFETY RECALL ***

NHTSA Recall No. (23E-054)

Cummins Campaign No. C2716

Campaign No. C2716

Dear Cummins OEM Customer:

OEM Customer:

We are writing to inform you that Cummins Inc. has determined that a safety-related defect exists in certain Cummins

Inc. has determined that a safety-related defect exists in certain Cummins B6.7 engines that are equipped with lifting bracket Option Number LA9181that were manufactured between March 20, 2023 and March 30, 2023. Cummins

B6.7 engines that are equipped with lifting bracket Option Number LA9181that were manufactured between March 20, 2023 and March 30, 2023. Cummins has initiated a recall of the subject B6.7 engines. Our records indicate that some of these engines were shipped to you.

has initiated a recall of the subject B6.7 engines. Our records indicate that some of these engines were shipped to you.

A copy of Cummins ’ initial Part 573 Defect Notification report is enclosed. This notification was submitted to the National Highway Traffic Safety Administration (NHTSA) on July 18, 2023. As more fully described in the Defect Notification, the subject engines may have been built with an insufficiently torqued (or loose) bolt attaching the rear lifting bracket to the cylinder head bracket that may detach from the cylinder head while the engine is being lifted, possibly causing the engine to swing or fall, potentially resulting in personal injury.

’ initial Part 573 Defect Notification report is enclosed. This notification was submitted to the National Highway Traffic Safety Administration (NHTSA) on July 18, 2023. As more fully described in the Defect Notification, the subject engines may have been built with an insufficiently torqued (or loose) bolt attaching the rear lifting bracket to the cylinder head bracket that may detach from the cylinder head while the engine is being lifted, possibly causing the engine to swing or fall, potentially resulting in personal injury.

Enclosed is a list of serial numbers for affected engines that our records indicate were shipped to your plants. For engines that have left your control, we encourage you to make a safety defect determination in accordance with 49 USC 30118 et seq. and, as appropriate, to submit a Defect Notification to NHTSA in accordance with 49 CFR Part 573. Cummins will conduct the recall, including notifying owners pursuant to 49 CFR Part 577, performing the remedy, and submitting quarterly status reports to NHTSA. Cummins

will conduct the recall, including notifying owners pursuant to 49 CFR Part 577, performing the remedy, and submitting quarterly status reports to NHTSA. Cummins is requesting that you provide the associated VINs and owner contact information to facilitate owner notification. Please work with your Cummins

is requesting that you provide the associated VINs and owner contact information to facilitate owner notification. Please work with your Cummins account team leader to ensure that the requested information is provided to Cummins

account team leader to ensure that the requested information is provided to Cummins as soon as possible.

as soon as possible.

As an equipment manufacturer, Cummins has no obligation to file a defect notification to Transport Canada for this recall. If an OEM has an obligation to report the defect to Transport Canada, we ask that you please provide the Transport Canada recall number for your vehicle recall to Cummins

has no obligation to file a defect notification to Transport Canada for this recall. If an OEM has an obligation to report the defect to Transport Canada, we ask that you please provide the Transport Canada recall number for your vehicle recall to Cummins . Cummins

. Cummins cannot mail owner letters compliant with Transport Canada regulations without the recall number assigned by Transport Canada. Cummins

cannot mail owner letters compliant with Transport Canada regulations without the recall number assigned by Transport Canada. Cummins will provide information to the OEM after mailings are completed so that the OEM can submit the required reports to Transport Canada.

will provide information to the OEM after mailings are completed so that the OEM can submit the required reports to Transport Canada.

Please note that Federal law prohibits delivery of these engines, or vehicles equipped with these engines, under a sale or lease until this condition has been remedied.

Cummins is finalizing the plan to make a field service safety campaign available to address this condition and will advise you when the schedule is known.

is finalizing the plan to make a field service safety campaign available to address this condition and will advise you when the schedule is known.

Cummins apologizes for this inconvenience, but we are initiating this action in the interest of our customers’ safety and satisfaction with our products. Thank you for your assistance.

apologizes for this inconvenience, but we are initiating this action in the interest of our customers’ safety and satisfaction with our products. Thank you for your assistance.

Chronology :

04/06/2023 – Navistar reported to Cummins

reported to Cummins that an engine had a bracket separation on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head.

that an engine had a bracket separation on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head.

04/13/2023 – Another OEM reported to Cummins that two engines had bracket separations on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. As a result, Cummins

that two engines had bracket separations on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. As a result, Cummins inspected and, as necessary, repaired all the engines at that OEM. Because of this action, no engines shipped to this OEM are subject to this recall. Cummins

inspected and, as necessary, repaired all the engines at that OEM. Because of this action, no engines shipped to this OEM are subject to this recall. Cummins implemented assembly process and operator training improvements at the lifting bracket assembly station.

implemented assembly process and operator training improvements at the lifting bracket assembly station.

06/09/2023 – Cummins conducted a Product Safety Hazard Analysis to evaluate the potential safety risk on fielded units. As part of this analysis, Cummins

conducted a Product Safety Hazard Analysis to evaluate the potential safety risk on fielded units. As part of this analysis, Cummins conducted a warranty search and found no claims for this issue.

conducted a warranty search and found no claims for this issue.

06/09/2023 – 07/11/2023 – Cummins escalated the issue through its Product Safety Defect Determination Process.

escalated the issue through its Product Safety Defect Determination Process.

7/11/2023 – Based upon the results of the investigation, and although Cummins has no reports that defective units have been shipped beyond the OEM assembly plants, the Cummins

has no reports that defective units have been shipped beyond the OEM assembly plants, the Cummins Product Safety Defect Board decided out of an abundance of caution to conduct a safety campaign to address this condition. To date, there have been no reports of injuries related to this issue.

Product Safety Defect Board decided out of an abundance of caution to conduct a safety campaign to address this condition. To date, there have been no reports of injuries related to this issue.

1 Affected Product

Equipment

| BRAND | PART NO. | PRODUCTION DATES |

CUMMINS | B6.7 | |

4 Associated Documents

Recall Acknowledgement

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-23E054-4013.PDF 215.345KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-23E054-4845.pdf 407.719KB

Loading...

Loading...

Recall 573 Report – 8/8/2023

RCLRPT-23E054-5279.PDF 215.287KB

Loading...

Loading...

Latest Recalls Documents

- 【Extensive Compatibility】After the upgrade, the compatibility is wider and more accurate! HD601 heavy duty truck scanner supports all major truck models that comply with standard protocols (SAE J1939, SAE J1708, ISO 14230-4, ISO 15764-4 and ISO 9141-2, ISO 27145-4 and Euro6). Fits for Cummins

, Paccar

, Paccar , Detroit, Perkins, Freightliner

, Detroit, Perkins, Freightliner , International

, International , Peterbilt

, Peterbilt , Ford

, Ford , Class 4-Class 8 trucks, etc. It also check engine diagnosis on most cars, minivans and light trucks

, Class 4-Class 8 trucks, etc. It also check engine diagnosis on most cars, minivans and light trucks - 【 Full System Diagnostic】HD601 Diesel Scanner supports all system scans of heavy trucks compliant with standard protocols SAE J1939 & J1708, such as Engine, ABS

, Transmission, Braking System, ESP, EPS, Fuel System, etc, It is a great scan tool fits for Cummins

, Transmission, Braking System, ESP, EPS, Fuel System, etc, It is a great scan tool fits for Cummins , Caterpillar

, Caterpillar , Detroit, Perkins, Maxxforce, Bendix

, Detroit, Perkins, Maxxforce, Bendix ,Wabash

,Wabash , Wabaco, Haldex

, Wabaco, Haldex , Allison, Eaton

, Allison, Eaton heavy trucks, With this truck tool, you can get deep analysis data about the system and do some repairs by yourself, saving much time and money

heavy trucks, With this truck tool, you can get deep analysis data about the system and do some repairs by yourself, saving much time and money - 【Enhanced Diesel OBD Scanner】The HD601 Diesel OBD Scanner offers unparalleled diagnostic capabilities for heavy-duty trucks. Beyond code reading, clearing, and live data display, it retrieves vehicle information, freeze frames, and DTCs. With 6, 9, and 16 pin cables, it ensures compatibility with various engines. This scanner's real-world testing prowess ensures comprehensive support for a wide array of heavy-duty truck engines, making it an indispensable tool for truck diagnostics

- 【DTC Library】+【Life Time Free Update】The built-in DTC library allows you to retrieve the codes directly without searching for the definition in the book. Whether you are a professional mechanic or a DIY car owner, HD601 diesel scanner explains the existing problem, makes it easier for you to understand the codes definition and fix the problem faster. Plus, you get a lifetime free internet updates, so you always have the latest software for diagnostics in English and Spanish languages

- 【Friendly Design, Easy of Use】This scanner is plug and play, simple and convenient, and very friendly for beginners. With improved buttons for easy menu navigation. The excellent 2.8 inch LCD color screen makes it easy to view the displayed results and gives you a better overview of your car's problem areas and the identified codes. In addition, the processor is super-fast and responds without lagging, providing maximum comfort and efficiency in diagnostic and service work.

- 【Diesel Engines】HD500 heavy duty truck scanner is tailored to vehicles equipped with cummins

, cat, detroit, paccar

, cat, detroit, paccar , international

, international , hino and more engines. This diesel scan tool come with diverse adapters, including diesel 6 & 9 pin, CAT-9 pin, CAT-14 pin, 16 pin cable. It is engineered to deliver accurate and reliable diagnostics, ensuring compatibility and effective troubleshooting for your trucks. Tip: If your truck fault code is factory custom protocol, please enter the diagnostic menu, and then select the corresponding engine to test, so that your test data will be more accurate.(Please note that the HD500 does not have bidirectional and VGT calibration.)

, hino and more engines. This diesel scan tool come with diverse adapters, including diesel 6 & 9 pin, CAT-9 pin, CAT-14 pin, 16 pin cable. It is engineered to deliver accurate and reliable diagnostics, ensuring compatibility and effective troubleshooting for your trucks. Tip: If your truck fault code is factory custom protocol, please enter the diagnostic menu, and then select the corresponding engine to test, so that your test data will be more accurate.(Please note that the HD500 does not have bidirectional and VGT calibration.) - 【Advanced DPF Management】The longer a truck is in use, the more particles accumulate in the D.P.F and the more the D.P.F becomes clogged, affecting engine performance and emissions efficiency. This HD500 diesel scanner provides you with DPF regeneration, D.P.F reset, DPD, DPR status control and more functions to achieve efficient cleaning, optimise engine performance and prolong D.P.F life. Save maintenance costs by avoiding D.P.F replacement through regular D.P.F cleaning and D.P.F regeneration. All made easy with the HD500. Warm tips: the HD500 can't do dpf function on Isuzu

.

. - 【Cylinder Cut-off Services】The cylinder cut-off test can diagnose engine failure problems. The HD500 heavy duty truck scan tool sends a command to the ECU to cut off the injector of a cylinder to check if the injector of that cylinder is not working properly. If the engine speed drops more, the better the cylinder works; if the speed drop is not obvious or does not drop then the cylinder may be faulty; touch the high-pressure pipe between the common rail tube to the injector with your hand, the stronger the pulsation, the better the injection effect. This diesel scanner provides clear guidance for maintenance.

- 【Speed Limit Reset & ABS

】Limit setting enables you can check and set the engine speed and the vehicle road speed limit when the vehicle is stationary, which ensures driving safety. And this diesel scanner also can make you achieve a firm brake pedal by removing air from the ABS

】Limit setting enables you can check and set the engine speed and the vehicle road speed limit when the vehicle is stationary, which ensures driving safety. And this diesel scanner also can make you achieve a firm brake pedal by removing air from the ABS module. HD500 truck scanner helps you maintain commercial vehicle breakdowns at all times, saving you money efficiently and winning more business for you! Please note that the adjust the speed limit is supported by fewer vehicles (eg: the cummins

module. HD500 truck scanner helps you maintain commercial vehicle breakdowns at all times, saving you money efficiently and winning more business for you! Please note that the adjust the speed limit is supported by fewer vehicles (eg: the cummins engine cannot support speed limit adjust), please confirm the vehicke VIN with us before purchase.

engine cannot support speed limit adjust), please confirm the vehicke VIN with us before purchase. - 【Access All Major Systems with Ease】The HD500 heavy duty scanner truck diesel provides full diagnostic capabilities, covering the engine, ABS

, SRS, EPB, Park Brake Controller, DPF, etc. Comes with full HD OBD/EOBD/ OBD2 service modes, including read codes, erase codes, live data, etc. Allows you to quickly identify issues and perform necessary solutions.

, SRS, EPB, Park Brake Controller, DPF, etc. Comes with full HD OBD/EOBD/ OBD2 service modes, including read codes, erase codes, live data, etc. Allows you to quickly identify issues and perform necessary solutions.

- WHY NEXAS NL102+ Diagnostic Tool: Compared with many other heavy duty truck scanner, NL102+ diagnostic tool has more comprehensive diagnostic capabilities, supporting all system diagnostics for all major trucks that comply with standard protocols and full OBD2 functionality. In addition to read/clear codes, displaying live data, it also supports retrieving vehicle information, freezing frames, and DTC lookup. NL102+ OBD2 scanner comes with 6-pin, 9-pin, 16-pin connectors are available to ensure compatibility with a wide range of trucks. You'll get f-ree updates for life, so you always have the latest diagnostic software in English, Spanish and French

- Wide Compatibility: The NEXAS NL102+ heavy duty truck diagnostic scanner is compatible with all heavy-duty trucks that adhere to standard protocols (J1587, J1939, J1708). It covers a wide range of vehicle models, including Cummins

, Detroit, Caterpillar

, Detroit, Caterpillar , Freightliner

, Freightliner , International

, International , Kenworth

, Kenworth , John Deere, Peterbilt

, John Deere, Peterbilt , Sterling, Mack

, Sterling, Mack , Paccar

, Paccar , Western Star

, Western Star , Mercedes-Benz

, Mercedes-Benz , Volvo

, Volvo , Scania, MAN, Renault, ERF, Foden, Seddon-Atkinson, Iveco, DAF, SISU, STEYR, and ISUZU

, Scania, MAN, Renault, ERF, Foden, Seddon-Atkinson, Iveco, DAF, SISU, STEYR, and ISUZU . Additionally, it supports 10 modes of OBD testing for complete diagnostics and battery voltage monitoring on passenger cars and light vehicles (from Europe, America, and Asia) manufactured after 1996

. Additionally, it supports 10 modes of OBD testing for complete diagnostics and battery voltage monitoring on passenger cars and light vehicles (from Europe, America, and Asia) manufactured after 1996 - Save Up to Hundreds Money for All Heavy Duty Trucks: NEXAS NL102+ diesel scan tool supports accurate full system scanning for all heavy-duty trucks that comply with standard protocols (J1587, J1939, and J1708). This includes vehicle systems such as the engine, transmission, instrument panel, drivetrain, brake system, suspension, ABS

, ESP, EPS, fuel system, etc. The diagnostic scan tool communicates with the vehicle's computer to retrieve data stream information, allowing it to accurately pinpoint issues. This reduces the waste caused by blind part replacements, saving your time and hundreds or thousands of money

, ESP, EPS, fuel system, etc. The diagnostic scan tool communicates with the vehicle's computer to retrieve data stream information, allowing it to accurately pinpoint issues. This reduces the waste caused by blind part replacements, saving your time and hundreds or thousands of money - All OBD2 Function & Battery Health Monitoring: Compared with other products on the market that only support partial OBD2 functions, this OBD2 scanner supports all OBD2 functions: read/clear codes, live data, freeze frame data, I/M readiness, EVAP test, on-board monitor, O2 sensor test, vehicle information, and DTC lookup, this providing more analysis basis for professional technicians. By regularly detecting the status of the vehicle battery with NL102+ OBD scan tool, it helps to take measures before the battery completely fails to avoid the situation that the vehicle suddenly fails to start. It can accurately diagnose the battery's condition thus saving on repair costs

- Plug and Play & One-click for DTC: NEXAS NL102+ diesel scanner is user-friendly. It comes with an intuitive screen and easy-to-understand interface, making it accessible even for non-professionals to get started. And the built-in DTC library in the code reader allows you to directly retrieve codes without searching for definitions in books, making it easier to understand the code definitions and solve problems more quickly

- 【2025 NEWEST LAUNCH 1st Advanced Scan Tool Compatible With 12V&24V Vehicles】Design for Passenger&Commercial Vehicles 2 in1,work for Cars/Trucks/buses/trailers/excavators/diesel engine/pick-up/etc.

- 【J2534 Reprogramming with Smartlink C】Advanced OEM J2534 reprogramming,Helps access direct data online, replace existing software/firmware in ECU,program new ECUs and fix software-controlled issue.

- 【Over 60 Service Reset Functions + Bi-Directional + ECU Coding 】This scan tool can support ECU Coding,60+ reset service functions like SAS/EPB/TPMS/DPF/Oil/Brake/ABS

Bleed, Injector coding, etc.

Bleed, Injector coding, etc. - 【2025 BEST Advanced Hardware & All Systems Diagnosis+Topology Display 】Support All systems Diagnostic including ENG, AT, ECM, TCM, ABS

, SRS, BCM, BMS, TPMS, SAS, Fuel System, Light System and more.

, SRS, BCM, BMS, TPMS, SAS, Fuel System, Light System and more. - 【Wider Vehicle Coverage of 12V & 24V Vehicles + 25 Languages】LAUNCH X431 PRO3S+SMARTLINK HD automotive scanner is ALL-IN-ONE Scan Tool for 12V cars and 24V Heavy-duty trucks support CANFD & DOIP.

- Extend DPF Life and Avoid Costly Repairs: Enhance your truck's performance with focused DPF care; featuring DPF regeneration, reset, and DPR state control for engines like Cummins

, Detroit, Caterpillar

, Detroit, Caterpillar , and more; save $10,000 to $30,000 in potential repairs; improve fuel efficiency and extend engine life; maintain reliable operation and reduce maintenance costs over time

, and more; save $10,000 to $30,000 in potential repairs; improve fuel efficiency and extend engine life; maintain reliable operation and reduce maintenance costs over time - Designed for Cummins

Engine Vehicles: Fits almost all Cummins

Engine Vehicles: Fits almost all Cummins engines (ISB

engines (ISB , ISC, ISD, ISG, ISK, ISL, ISX, ISM, ISN, QSB, X12, X15

, ISC, ISD, ISG, ISK, ISL, ISX, ISM, ISN, QSB, X12, X15 , B6.7, L9

, B6.7, L9 , L9N, QSM11, and more) commonly found in trucks like Freightliner

, L9N, QSM11, and more) commonly found in trucks like Freightliner , Kenworth

, Kenworth , International

, International , Peterbilt

, Peterbilt , Mack

, Mack , Volvo

, Volvo , Western Star

, Western Star , Autocar, Terex, and school buses like Thomas/Blue Bird, It's also compatible with Komatsu/Sany machinery, Agrifac vehicles, RVs, and more. Note: For RVs with non-Cummins

, Autocar, Terex, and school buses like Thomas/Blue Bird, It's also compatible with Komatsu/Sany machinery, Agrifac vehicles, RVs, and more. Note: For RVs with non-Cummins engines, please confirm engine type to verify compatibility

engines, please confirm engine type to verify compatibility - Maximize Caterpillar

Engine Performance: Diesel scanner designed for Caterpillar

Engine Performance: Diesel scanner designed for Caterpillar engines (C7, C9, C11, C13, C15, C32, and more) in trucks like Caterpillar

engines (C7, C9, C11, C13, C15, C32, and more) in trucks like Caterpillar , Freightliner

, Freightliner , Peterbilt

, Peterbilt , and Kenworth

, and Kenworth . Features include code reading/clearing, live data streaming, ECU retrieval, DPF regeneration, and more; unlock your engine's full potential with enhanced diagnostics and maintenance

. Features include code reading/clearing, live data streaming, ECU retrieval, DPF regeneration, and more; unlock your engine's full potential with enhanced diagnostics and maintenance - Designed for Detroit Engine Trucks: This heavy duty truck scan tool is compatible with a wide range of heavy duty commercial trucks – class 7 and class 8, medium duty trucks, light duty trucks and semi-trucks equipped with Detroit engines, including DD13, DD15, DD16, Series 50, Series 60, MBE 900, MBE 4000, OM501, OM502, DDDL 6, and DDDL 7

- Designed for Paccar

Engine Trucks: This heavy-duty truck scanner diagnostic tool is specifically designed for Paccar

Engine Trucks: This heavy-duty truck scanner diagnostic tool is specifically designed for Paccar engines, including Paccar

engines, including Paccar PX-7, PX-9, MX-11, MX-13

PX-7, PX-9, MX-11, MX-13

- 🔥🔥🔥2025 New Functions Making X7 HD the Top Dog - Big Surprise!!! ANCEL X7 HD truck scanner 10 major functional advantages .✅>Full HDOBD/OBD2 Function ✅>ALL System Diagnostic ✅>42+ Reset Function ✅>Active Test / Bi-Directional Control✅>ECU Coding✅>Graphing Live Data✅>Wide Compatibility ✅>2 Yrs Free Update✅>Remote Operation✅>Bluetooth 5.0 & Wifi In addition, 8 major hardware advantages: ✅>6000 mAh✅>10.1 inch Tablet✅>2G RAM✅>32G ROM (Expandable to 128GB)✅>Data Record & Replay & Print✅>Android 10.0✅>Bluetooth 5.0 & Wifi✅>14 Languages

- 🚛OEM DPF Forced Regen & Cylinder Cutout Test & more - ANCEL X7 HD diesel scanner diagnostic tool not only supports DPF regeneration, DPF reset, DPF related information reset, DPR state reset, DPD forced regeneration etc, which helps you better solve the exhaust aftertreatment system problems, but also supports activate motor to do exhaust air in ABS

Automatically. Moreover, it features TPMS activation, cylinder cut-off and learning functions.

Automatically. Moreover, it features TPMS activation, cylinder cut-off and learning functions. - 🚛Advanced ECU Coding & Programming - ANCEL X7 HD 10.1inch truck scanner diagnostic tool is equipped with advanced ECU coding, supports Level calibration, Idle speed learning and Adjustment, Camshaft timing control learning, Control unit adaptations, Injector Codes, Read/Write VIN, Road speed limit optional vehicle speed set, etc... PLEASE NOTE that ECU codes are not compatible with all vehicles, please send us your VIN# to check vehicle compatibility.

- 🚛42+ Reset Functions & Bidirectional Control - 2025 newest top heavy duty truck scan tool, comes with 42+ special services (ECU, Speed Limit and Idle Reset, Oil Reset, Injector Coding, EPB, ABS

, SRS, Suspension, Throttle, etc. and always keep growing), which meet all your various needs for service and maintenance. Please send your VIN# to our 💌 amazon@anceltech.com 💌 to check compatibility.

, SRS, Suspension, Throttle, etc. and always keep growing), which meet all your various needs for service and maintenance. Please send your VIN# to our 💌 amazon@anceltech.com 💌 to check compatibility. - 🚛10 Inch All Systems Diesel Scanner & Full HDOBD/OBD2 Modes - ANCEL X7 HD diesel truck scan tool supports all systems scan, such as Engine, Brake, Retarder, TECU Transmission, Tachograph, ABS

, SRS, TPMS, EPB, SAS, ESP, and other vehicle systems, comes with 10 obd2 service modes: read/erase error codes, Data Stream, I/M Readiness, Vehicle Information, Actuations, DTC Lookup, EVAP, view freeze frame, etc.

, SRS, TPMS, EPB, SAS, ESP, and other vehicle systems, comes with 10 obd2 service modes: read/erase error codes, Data Stream, I/M Readiness, Vehicle Information, Actuations, DTC Lookup, EVAP, view freeze frame, etc.

- 👨⚕️D.P.F Cleaner Doctor: As a long-term truck user, do you still struggle with clogged filters and engine slowdowns? The HD3300 PLUS+ professional DPF regeneration scanner offers complete D.P.F reset/forced regen, DPR status monitoring, and DPD regeneration capabilities to enhance engine performance and emission control efficiency. Compatible with Cummins

, Detroit, Cat, International

, Detroit, Cat, International , Volvo

, Volvo , Mack

, Mack , Paccar

, Paccar , Isuzu

, Isuzu , Hino, and Fuso major diesel engine brands. This heavy duty truck scanner effectively prevents soot and particulate buildup, helping you avoid costly ($4000 -$8000 ) D.P.F replacements.

, Hino, and Fuso major diesel engine brands. This heavy duty truck scanner effectively prevents soot and particulate buildup, helping you avoid costly ($4000 -$8000 ) D.P.F replacements. - 🌐Widely Compatible: This heavy duty truck scanner includes adapters like CAT-9 PIN, DIESEL 6&9 PIN, and OBD 16 PIN, supporting protocols such as J1587, J1939, J1708, J27145, ISO9141-2, ISO14230-2, and ISO15765-4. Built for heavy duty trucks or semi trucks with Cummins

, Caterpillar

, Caterpillar , Detroit, and Paccar

, Detroit, and Paccar . So, this truck scanner diagnostic tool fit for Freightliner

. So, this truck scanner diagnostic tool fit for Freightliner , Peterbilt

, Peterbilt , Volvo

, Volvo HD, Mack

HD, Mack , International

, International , Ford

, Ford HD trucks. ANCEL HD3300 PLUS+ truck scanner ensures precise diagnostics and seamless problem-solving for an unparalleled user journey.

HD trucks. ANCEL HD3300 PLUS+ truck scanner ensures precise diagnostics and seamless problem-solving for an unparalleled user journey. - 🐋Full System Diesel Diagnostic Tool: HD3300 Plus+ diesel scanner diagnostic tool provides depth diagnostics for all major systems, including Engine, Transmission, ABS

, EBS, ESC, ASR, Airbag, BCM, SCR, Instrument, Air Suspension, and DPF. As an ALL-IN-ONE diesel scanner, it supports HD OBD & OBD2 service modes, such as read/erase codes, and live data stream, ensuring quick and precise issue identification for optimal performance.

, EBS, ESC, ASR, Airbag, BCM, SCR, Instrument, Air Suspension, and DPF. As an ALL-IN-ONE diesel scanner, it supports HD OBD & OBD2 service modes, such as read/erase codes, and live data stream, ensuring quick and precise issue identification for optimal performance. - 💦Anvanced Oil Light Reset Function: Changing oil is the most important part of routine maintenance for vehicle. HD3300 PLUS+ obd2 scanner for diesel trucks support OEM level oil reset for ISUZU

& FUSO &HINO, help reset the Oil Life Reminder (turn off the Oil Service Light) when the replacement of engine oil is done in case of the impurities in oil may damage the engine. So vehicles can recalculate another optimal oil life change interval depending on the vehicle driving conditions and climate, makes your driving safety gets ensuring.

& FUSO &HINO, help reset the Oil Life Reminder (turn off the Oil Service Light) when the replacement of engine oil is done in case of the impurities in oil may damage the engine. So vehicles can recalculate another optimal oil life change interval depending on the vehicle driving conditions and climate, makes your driving safety gets ensuring. - 🏅Economize Your Budget: NO HIDDING UPDATE FEES!! The ANCEL HD3300 Plus+ diesel mechanic tools offers one-click Lifetime F*ree Update, keeping you up-to-date with the latest features. Expert technical support for you a hassle-fr*ee experience. With this scanner, it can keep an eye on your truck condition in time!

- 🚜【2025 Top-level Diagnostic Tool, Ideal for Commercial Vehicles】: LAUNCH 129HD heavy duty truck scanner is supports more than 50+ vehicle models, such as light/heavy truck, pickup, buses, trailer, tractor, dumper, agricultural and construction vehicles. It delivers such as DPF regen, speed limit adjustment. 129HD also includes 7+ special services, full system functions, EOBD/HDOBD/OBD2 functions, graphing live data, data screenshot/feedback/Email, 2 year free-update and 24/7 customer service.

- 🚚【7+ Special Service Cover 99% Commercial Vehicles】: LAUNCH 129HD diesel truck obd2 scanner is designed for commercial vehicles, it contain 7+ special service for mechanics to do daily auto maintenance in workshops, such as DPF Regen, Oil Reset, Speed Limit Adjustment, ABS

bleeding, Injector Coding, Cylinder Deactivation Compression, Clutch Relearn and so on. It can help you handle faults for commercial vehicles, save your money, quickly & efficiently, and win more business!

bleeding, Injector Coding, Cylinder Deactivation Compression, Clutch Relearn and so on. It can help you handle faults for commercial vehicles, save your money, quickly & efficiently, and win more business! - 🚛【Wide Vehicle Range of Compatibility】:LAUNCH 129HD diagnostic tool is designed to work with OBD2/CAN, J1587, J1708 and J1939 compatible vehicles. It support 99% commercial vehicles and 300+ vehicle models. It fit for Cummins

, Caterpillar

, Caterpillar , Detroit, International

, Detroit, International , Paccar

, Paccar , Volvo

, Volvo , Freightliner

, Freightliner , Kenworth

, Kenworth , Isuzu

, Isuzu , Hino, Western Star

, Hino, Western Star , Sterling, Peterbilt

, Sterling, Peterbilt , Maxxforce, Peterbilt

, Maxxforce, Peterbilt , Maxxforce, Scania, Man, DAF, Mercedes-Benz

, Maxxforce, Scania, Man, DAF, Mercedes-Benz , USAFORD,Aisin, Allison, Case, Credo, Deutz and so on.

, USAFORD,Aisin, Allison, Case, Credo, Deutz and so on. - 🚌【OE-Level Full System Diagnostic &Remote Diagnose】:LAUNCH 129HD heavy truck scanner offers full system functions to make the comprehensive diagnostic. It works on Engine, ABS, SRS, SAS, Transmission, TPMS, ESP, EPB, Brake, Park Brake Controller, DPF, Immobilizer, etc, allows you to quickly and comprehensively identify fault problems. You can send the diagnostic report and feedback to remote system or service center, enabling real-time monitoring of multiple vehicles and proactive maintenance scheduling.

- 🚎【Adcanced DPF Regeneration & Speed Limited Adjust Function】: The DPF function of 129HD integrates monitoring, control, analysis and fault diagnosis capabilities to ensure that the DPF system can operate effectively under various operating condition. It applied to 50+ engine models such as Cummins

Caterpillar

Caterpillar Detroit International

Detroit International Paccar

Paccar Volvo

Volvo Peterbilt

Peterbilt . Remote diagnose will transmittethe diagnostic report/feedback to a remote system or service center, which will offer a professional suggestion for your vehicles.

. Remote diagnose will transmittethe diagnostic report/feedback to a remote system or service center, which will offer a professional suggestion for your vehicles.

- 【Wide Compatibility】HD430 supports 12V 24V trucks, equipped with diesel connectors (CAT-9, Diesel 6pin & 9pin) and OBDII 16pin, with strong truck adaptation and compatibility. Product supports SAE J1939, SAE J1708, SAE J1850 PWM, SAE J1850 VPW, ISO 14230-4, ISO 9141-2, ISO 15765-4, ISO 27145-4 truck protocols, provides complete scan & fast scan, and available in English and Spanish, it is suitable for DIY enthusiasts, old-school mechanics, truck owners or small repair shops.

- 【 D.P.F Regen For Cunmmis & Caterpillar

】HD430 supports Cummins

】HD430 supports Cummins and Caterpillar

and Caterpillar engines for D.P.F reset & regeneration, helping to remove diesel particles from truck D.P.F & meet maintenance schedules, thereby avoiding fault codes, maintaining engine performance, and extending DPF & truck life. Even if you aren't a professional mechanic, you can easily perform D.P.F regen using HD430 according to clear instructions, which can help your truck avoid roadside obstacles while reducing your repair time & cost. ❕Note: Not compatible with pickups.

engines for D.P.F reset & regeneration, helping to remove diesel particles from truck D.P.F & meet maintenance schedules, thereby avoiding fault codes, maintaining engine performance, and extending DPF & truck life. Even if you aren't a professional mechanic, you can easily perform D.P.F regen using HD430 according to clear instructions, which can help your truck avoid roadside obstacles while reducing your repair time & cost. ❕Note: Not compatible with pickups. - 【Diesel Full System Diagnostic Tool】HD430 has excellent diagnostic performance, quickly scanning truck systems, detecting truck faults, while supporting the engine, ABS, transmission, fuel system and more. Read the fault code and DTC Lookup help you understand the cause of the fault, quickly clear the fault code after maintenance, so provide you with good maintenance assistance and convenience. HD430 heavy duty truck scanner will provide efficient, fast scanning of your truck system.

- 【Enhanced Diesel & Gasoline Scanner】HD430 has full HD OBD/EOBD/OBDII functions and supports heavy duty trucks with Cummins

, Caterpillar

, Caterpillar , Detroit and Paccar engines. In addition to read & clear fault codes, view live data, ECUs, vehicle information, it also supports functions such as freeze frame, I/M readiness, on-board monitor test, etc. At the same time, the built-in DTC Lookup can help you quickly query and understand the specific definition of the fault code & solve the problem, providing strong support & convenience for your vehicle maintenance.

, Detroit and Paccar engines. In addition to read & clear fault codes, view live data, ECUs, vehicle information, it also supports functions such as freeze frame, I/M readiness, on-board monitor test, etc. At the same time, the built-in DTC Lookup can help you quickly query and understand the specific definition of the fault code & solve the problem, providing strong support & convenience for your vehicle maintenance. - 【Advanced Hardware & Design】4.3-inch screen, 8G memory, 8G TF, 2.4G Wifi & other hardware, your truck repair process will be more stable. Wifi Lifetime Free Update, you can always keep up with the latest diagnostic functions and optimized performance of HD430, compared with others, you can avoid expensive update subscription fees. The imperial conversion to meet your needs for the use of the unit of measurement. Unique horizontal screen button design, your operation will be more comfortable and convenient.

- PLEASE NOTE: If you encounter any quality issues or notice signs of use upon receiving your product, please e-m ail us at toptool-service@outlook.com with your order number and photos. We will gladly provide FREE replacements to ensure your satisfaction. Thank you for your cooperation

- 【DPF Reset & Forced Regen for Cummins

& Cat】 ANCEL HD100 heavy duty truck scanner supports DPF reset and forced regeneration for Cummins

& Cat】 ANCEL HD100 heavy duty truck scanner supports DPF reset and forced regeneration for Cummins (X15, X12, ISX, etc.) and Caterpillar

(X15, X12, ISX, etc.) and Caterpillar (C7, C9, C13, etc.) diesel engines. This professional DPF regeneration tool helps you save on costly DPF replacements and improve fuel efficiency. Confirm your vehicle’s VIN with us before purchase (toptool-service@outlook.com)

(C7, C9, C13, etc.) diesel engines. This professional DPF regeneration tool helps you save on costly DPF replacements and improve fuel efficiency. Confirm your vehicle’s VIN with us before purchase (toptool-service@outlook.com) - 【One-Click DPF Management – No Dealer Required】 Perform DPF regeneration and reset in just one click, avoiding expensive repair shop visits. Frequent short trips cause DPF clogs, leading to reduced fuel efficiency or even truck breakdowns. With ANCEL HD100 truck scanner, resolve these aftertreatment issues in 30 minutes, getting your semi truck or diesel truck back on the road fast

- 【Full-System Diesel Scanner for Heavy Duty Trucks】This ANCEL HD100 provides mechanic-level diagnostics for Freightliner

, Paccar, Kenworth

, Paccar, Kenworth , Peterbilt

, Peterbilt , International

, International , Volvo

, Volvo , Mack, Western Star

, Mack, Western Star , semi trucks, and buses. Read and clear codes for engine (Cummins

, semi trucks, and buses. Read and clear codes for engine (Cummins , Caterpillar

, Caterpillar , Detroit, Paccar), ABS, and transmission (Allison, Bendix, Eaton, Wabco, ZF). Supports SAE J1939, SAE J1708, SAE J1850 PWM, SAE J1850 VPW, ISO 14230-4, ISO 9141-2, ISO 15765-4, ISO 27145-4 standard protocols

, Detroit, Paccar), ABS, and transmission (Allison, Bendix, Eaton, Wabco, ZF). Supports SAE J1939, SAE J1708, SAE J1850 PWM, SAE J1850 VPW, ISO 14230-4, ISO 9141-2, ISO 15765-4, ISO 27145-4 standard protocols - 【2-in-1 OBD2 Scanner for Diesel Trucks】 ANCEL HD100 functions as both a heavy-duty truck diagnostic tool and an OBD2 code reader. Diagnose truck engines, ABS, and transmission or check car engine codes with freeze frame data, real-time data, and I/M readiness. Ensure your truck or car passes its annual inspection with ease

SEOCONTENT-START

OMB Control No.: 2127-0004 Part 573 Safety Recall Report 23E-054 The information contained in this report was submitted pursuant to 49 CFR §573 Manufacturer Name : Cummins, Inc. Submission Date : JUL 18, 2023 NHTSA Recall No. : 23E-054 Manufacturer Recall No. : C2716 Manufacturer Information : Manufacturer Name : Cummins, Inc. Address : Box 3005 Mail Code COB118 Columbus IN 47202-3005 Company phone : 812-377-5000 Population : Number of potentially involved : 59 Estimated percentage with defect : 45 % Equipment Information : Brand / Trade 1 : Cummins Inc Model : B6.7 Part No. : D313038BX03 Size : N/A Function : Diesel Engine Descriptive Information : This recall covers certain Cummins B6.7 engines that are equipped with lifting bracket Option Number LA9181 and were built during the identified product date range and sold exclusively to Navistar for installation in trucks and buses. The production “Begin” and “End” dates provided herein are based on the dates list on the affected engines’ dataplates (the engine “build date”.) Production Dates : MAR 20, 2023 – MAR 30, 2023 Description of Defect : Description of the Defect : The subject engines may have been built with an insufficiently torqued (or loose) bolt attaching the rear lifting bracket to the cylinder head. FMVSS 1 : NR FMVSS 2 : NR Description of the Safety Risk : The rear lifting bracket may detach from the cylinder head while the engine is being lifted, possibly causing the engine to swing or fall, potentially resulting in personal injury. Description of the Cause : The lower bolt that attaches the rear lifting bracket to the cylinder head may not have been properly torqued due to assembly operator error. Part 573 Safety Recall Report 23E-054 Page 2 The information contained in this report was submitted pursuant to 49 CFR §573 Identification of Any Warning that can Occur : None. Involved Components : Component Name : Bracket, Engine Lifting Component Description : Rear Lifting Bracket Component Part Number : 4933232 Component Name : Screw, Hex Flange Head Component Description : Lower Bolt Component Part Number : 3903990 Supplier Identification : Component Manufacturer Name : N/A Address : NR NR Country : NR Chronology : 04/06/2023 – Navistar reported to Cummins that an engine had a bracket separation on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. 04/13/2023 – Another OEM reported to Cummins that two engines had bracket separations on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. As a result, Cummins inspected and, as necessary, repaired all the engines at that OEM. Because of this action, no engines shipped to this OEM are subject to this recall. Cummins implemented assembly process and operator training improvements at the lifting bracket assembly station. 06/09/2023 – Cummins conducted a Product Safety Hazard Analysis to evaluate the potential safety risk on Part 573 Safety Recall Report 23E-054 Page 3 The information contained in this report was submitted pursuant to 49 CFR §573 fielded units. As part of this analysis, Cummins conducted a warranty search and found no claims for this issue. 06/09/2023 – 07/11/2023 – Cummins escalated the issue through its Product Safety Defect Determination Process. 7/11/2023 – Based upon the results of the investigation, and although Cummins has no reports that defective units have been shipped beyond the OEM assembly plants, the Cummins Product Safety Defect Board decided out of an abundance of caution to conduct a safety campaign to address this condition. To date, there have been no reports of injuries related to this issue. Description of Remedy : Description of Remedy Program : The remedy is to inspect the rear lifting bracket bolts, rear lifting bracket, fuel lines and cylinder head for damage. If any bolt is observed loose or insufficiently torqued, the bracket and both bolts will be replaced. Fuel lines or cylinders heads found damaged will also be replaced. Cummins requests that it be exempt from providing notification of a reimbursement plan. Any pre-notification product failure would have been corrected under the manufacturer’s limited warranty. Accordingly, no person would be eligible for reimbursement pursuant to 573.13. How Remedy Component Differs from Recalled Component : The remedy components are the same as the recalled components because the issue is an assembly error. Identify How/When Recall Condition was Corrected in Production : Assembly process and operator training improvements at the lifting bracket assembly station were implemented on 4/13/2023. Recall Schedule : Description of Recall Schedule : Cummins expects to notify Navistar, the only affected OEM, by 07/28/2023. Subject to consultation and agreement with Navistar, Cummins will conduct the recall, including sending owner notifications. The timing of owner notification will be determined in consultation with Navistar. The notification and remedy schedule is still being developed, and Cummins will revise the “planned notification” dates when a more precise schedule is known. In any event, Cummins expects to notify owners no later than 9/15/2023, pending availability of owner addresses from Navistar. Planned Dealer Notification Date : NR – NR Planned Owner Notification Date : SEP 15, 2023 – SEP 15, 2023 Part 573 Safety Recall Report 23E-054 Page 4 The information contained in this report was submitted pursuant to 49 CFR §573 Purchaser Information : The following manufacturers purchased this defective/noncompliant equipment for possible use or installation in new motor vehicles or new items of motor vehicle equipment: Name : Navistar International Address : 2701 Navistar Dr Lisle IL 60532 Country : US Company Phone : 2606155684 * NR – Not Reported

Address : 2701 Navistar Dr Lisle IL 60532 Country : US Company Phone : 2606155684 * NR – Not Reported

**************************************************************************************************************

*** IMPORTANT SAFETY RECALL *** NHTSA Recall No. (23E-054) Cummins Campaign No. C2716 July 21, 2023 Dear Cummins OEM Customer: We are writing to inform you that Cummins Inc. has determined that a safety-related defect exists in certain Cummins B6.7 engines that are equipped with lifting bracket Option Number LA9181that were manufactured between March 20, 2023 and March 30, 2023. Cummins has initiated a recall of the subject B6.7 engines. Our records indicate that some of these engines were shipped to you. A copy of Cummins’ initial Part 573 Defect Notification report is enclosed. This notification was submitted to the National Highway Traffic Safety Administration (NHTSA) on July 18, 2023. As more fully described in the Defect Notification, the subject engines may have been built with an insufficiently torqued (or loose) bolt attaching the rear lifting bracket to the cylinder head bracket that may detach from the cylinder head while the engine is being lifted, possibly causing the engine to swing or fall, potentially resulting in personal injury. Enclosed is a list of serial numbers for affected engines that our records indicate were shipped to your plants. For engines that have left your control, we encourage you to make a safety defect determination in accordance with 49 USC 30118 et seq. and, as appropriate, to submit a Defect Notification to NHTSA in accordance with 49 CFR Part 573. Cummins will conduct the recall, including notifying owners pursuant to 49 CFR Part 577, performing the remedy, and submitting quarterly status reports to NHTSA. Cummins is requesting that you provide the associated VINs and owner contact information to facilitate owner notification. Please work with your Cummins account team leader to ensure that the requested information is provided to Cummins as soon as possible. As an equipment manufacturer, Cummins has no obligation to file a defect notification to Transport Canada for this recall. If an OEM has an obligation to report the defect to Transport Canada, we ask that you please provide the Transport Canada recall number for your vehicle recall to Cummins. Cummins cannot mail owner letters compliant with Transport Canada regulations without the recall number assigned by Transport Canada. Cummins will provide information to the OEM after mailings are completed so that the OEM can submit the required reports to Transport Canada. Please note that Federal law prohibits delivery of these engines, or vehicles equipped with these engines, under a sale or lease until this condition has been remedied. Cummins is finalizing the plan to make a field service safety campaign available to address this condition and will advise you when the schedule is known. Cummins apologizes for this inconvenience, but we are initiating this action in the interest of our customers’ safety and satisfaction with our products. Thank you for your assistance. Please confirm receipt of this communication. Sincerely, OEM Service and Quality Manager Enclosures: 1. Cummins Part 573 Defect Notification 2. List of ESNs

**************************************************************************************************************

OMB Control No.: 2127-0004 Part 573 Safety Recall Report 23E-054 The information contained in this report was submitted pursuant to 49 CFR §573 Manufacturer Name : Cummins, Inc. Submission Date : AUG 08, 2023 NHTSA Recall No. : 23E-054 Manufacturer Recall No. : C2716 Manufacturer Information : Manufacturer Name : Cummins, Inc. Address : Box 3005 Mail Code COB118 Columbus IN 47202-3005 Company phone : 812-377-5000 Population : Number of potentially involved : 59 Estimated percentage with defect : 45 % Equipment Information : Brand / Trade 1 : Cummins Inc Model : B6.7 Part No. : D313038BX03 Size : N/A Function : Diesel Engine Descriptive Information : This recall covers certain Cummins B6.7 engines that are equipped with lifting bracket Option Number LA9181 and were built during the identified product date range and sold exclusively to Navistar for installation in trucks and buses. The production “Begin” and “End” dates provided herein are based on the dates list on the affected engines’ dataplates (the engine “build date”.) Production Dates : MAR 20, 2023 – MAR 30, 2023 Description of Defect : Description of the Defect : The subject engines may have been built with an insufficiently torqued (or loose) bolt attaching the rear lifting bracket to the cylinder head. FMVSS 1 : NR FMVSS 2 : NR Description of the Safety Risk : The rear lifting bracket may detach from the cylinder head while the engine is being lifted, possibly causing the engine to swing or fall, potentially resulting in personal injury. Description of the Cause : The lower bolt that attaches the rear lifting bracket to the cylinder head may not have been properly torqued due to assembly operator error. Part 573 Safety Recall Report 23E-054 Page 2 The information contained in this report was submitted pursuant to 49 CFR §573 Identification of Any Warning that can Occur : None. Involved Components : Component Name : Bracket, Engine Lifting Component Description : Rear Lifting Bracket Component Part Number : 4933232 Component Name : Screw, Hex Flange Head Component Description : Lower Bolt Component Part Number : 3903990 Supplier Identification : Component Manufacturer Name : N/A Address : NR NR Country : NR Chronology : 04/06/2023 – Navistar reported to Cummins that an engine had a bracket separation on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. 04/13/2023 – Another OEM reported to Cummins that two engines had bracket separations on their production line due to a loose bolt attaching the rear lifting bracket to the cylinder head. As a result, Cummins inspected and, as necessary, repaired all the engines at that OEM. Because of this action, no engines shipped to this OEM are subject to this recall. Cummins implemented assembly process and operator training improvements at the lifting bracket assembly station. 06/09/2023 – Cummins conducted a Product Safety Hazard Analysis to evaluate the potential safety risk on Part 573 Safety Recall Report 23E-054 Page 3 The information contained in this report was submitted pursuant to 49 CFR §573 fielded units. As part of this analysis, Cummins conducted a warranty search and found no claims for this issue. 06/09/2023 – 07/11/2023 – Cummins escalated the issue through its Product Safety Defect Determination Process. 7/11/2023 – Based upon the results of the investigation, and although Cummins has no reports that defective units have been shipped beyond the OEM assembly plants, the Cummins Product Safety Defect Board decided out of an abundance of caution to conduct a safety campaign to address this condition. To date, there have been no reports of injuries related to this issue. Description of Remedy : Description of Remedy Program : The remedy is to inspect the rear lifting bracket bolts, rear lifting bracket, fuel lines and cylinder head for damage. If any bolt is observed loose or insufficiently torqued, the bracket and both bolts will be replaced. Fuel lines or cylinders heads found damaged will also be replaced. Cummins requests that it be exempt from providing notification of a reimbursement plan. Any pre-notification product failure would have been corrected under the manufacturer’s limited warranty. Accordingly, no person would be eligible for reimbursement pursuant to 573.13. How Remedy Component Differs from Recalled Component : The remedy components are the same as the recalled components because the issue is an assembly error. Identify How/When Recall Condition was Corrected in Production : Assembly process and operator training improvements at the lifting bracket assembly station were implemented on 4/13/2023. Recall Schedule : Description of Recall Schedule : Cummins expects to notify Navistar, the only affected OEM, by 07/28/2023. Subject to consultation and agreement with Navistar, Cummins will conduct the recall, including sending owner notifications. The timing of owner notification will be determined in consultation with Navistar. Cummins expects to release a safety campaign by August 24, 2023. In any event, Cummins expects to notify owners no later than 9/15/2023, pending availability of owner addresses from Navistar. Planned Dealer Notification Date : AUG 24, 2023 – AUG 24, 2023 Planned Owner Notification Date : SEP 15, 2023 – SEP 15, 2023 Part 573 Safety Recall Report 23E-054 Page 4 The information contained in this report was submitted pursuant to 49 CFR §573 Purchaser Information : The following manufacturers purchased this defective/noncompliant equipment for possible use or installation in new motor vehicles or new items of motor vehicle equipment: Name : Navistar International Address : 2701 Navistar Dr Lisle IL 60532 Country : US Company Phone : 2606155684 * NR – Not Reported

**************************************************************************************************************

**************************************************************************************************************

SEOCONTENT-END

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.