| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA Campaign Number: 18E088

Manufacturer AXN Heavy Duty LLC

Components SUSPENSION

Potential Number of Units Affected 1,569

Wheel End Separation from Axle

If the wheel end separates from the axle, it can increase the risk of a crash.

Summary

AXN Heavy Duty LLC (AXN) is recalling certain Trailer Axles. The wheel end nut locking device on these trailers may not be properly installed, allowing the wheel end to separate from the axle.

Remedy

AXN has notified the trailer manufacturers that purchased the axles, and dealers for those manufacturers will inspect the locking clip to ensure its proper installation, correcting it as necessary, free of charge. The recall began on August 29, 2018. Owners may contact AXN customer service at 1-502-882-9122.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Pro-Torq Inspection Procedure

ACTION PLAN: Pro-Torq Retaining Clip (Keeper) Inspection

August 29, 2018 RevC

SAFETY STATEMENT

Always consult with your Certified Safety Administrator prior to any Inspections or Procedures.

AXN Heavy Duty, LLC shall not be held liable for any actions or damage incurred during Inspections or Procedures.

REQUIRED INSPECTION PROCEDURE:

- Remove Hub Cap and discard gasket.

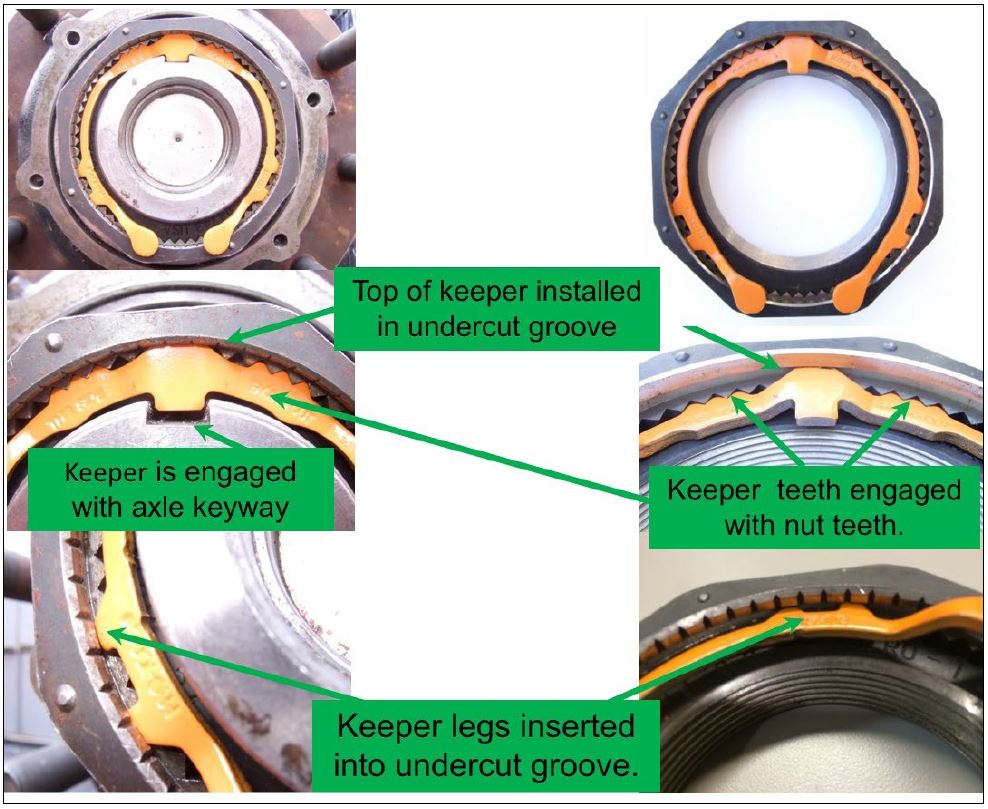

- Visually verify presence of Pro-Torq Retaining Clip (Keeper) (see Figure 1).

- Verify the mating teeth are engaged and the keeper tab and keeper arms are fully seated into the undercut groove in the Pro-Torq Wheel Nut (Figure 1). If all of these conditions are NOT met, see CORRECTIVE ACTIONS

#1 – CORRECTIVE ACTION – if Pro-Torq Keeper is present and mating teeth are engaged properly, but a keeper arm does NOT seem to be engaged in groove:

| #2 – CORRECTIVE ACTION – if Pro-Torq Keeper is missing or mating teeth are NOT engaged:

|

Figure 1: Pro-Torq Wheel-end Nut and Retaining clip Proper Installation

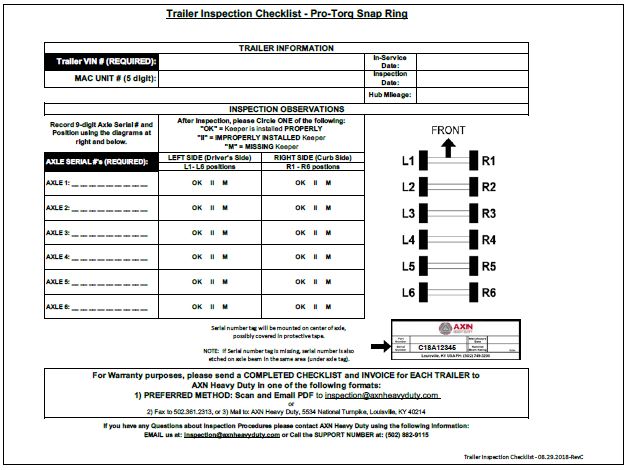

Figure 2: Trailer Inspection Checklist

STEMCO PRO-Torq Instructions

Step 1: Remove the Keeper from the nut

Use a small screwdriver to carefully pry the keeper arm from the undercut groove on each side until the keeper is released.

Step 2:

Thread the nut onto the axle until hand tight against the bearing

Step 3: Seat the Bearing

With hub/drum only:

Using a torque wrench:

A.

(1) Tighten the Nut to 200 ft-lbs. Spin the wheel at least one full rotation.

(2) Tighten the Nut to 200 ft-lbs. Spin the wheel at least one full rotation.

(3) Tighten the nut to 200 ft-lbs. B. Back the nut off until it is loose.

B. Back the nut off until it is loose.

With hub/drum/wheels:

A. Tighten the nut to 200 ft-lbs while the wheel is rotating.

B. Back the nut off until it is loose.

Step 4: Adjust the Bearing

With hub/drum only:

Using a torque wrench:

A.

(1) Tighten the Nut to 100 ft-lbs. Spin the wheel at least one full rotation.

(2) Tighten the Nut to 100 ft-lbs. Spin the wheel at least one full rotation.

(3) Tighten the nut to 100 ft-lbs.

B. Back the nut off one raised face mark.

With hub/drum/wheels:

Using a torque wrench:

A. Tighten the nut to 100 ft-lbs while the wheel is rotating.

B. Back the nut off one raised face mark.

WARNING! Failure to follow this instruction could cause the wheel to come off and cause bodily injury. Failure to back off the nut will cause the bearing to run hot and be damaged.

Step 5: Install the Keeper

ORANGE SIDE FACING OUT

A. Insert the keeper tab into the undercut groove of the nut and engage the keyway tang in the axle keyway. Insert keeper tab with the orange side facing out.

B. Engage the mating teeth.

C. Compress and insert the keeper arms, one at a time, into the undercut groove with a small screwdriver.

NOTE: Recommended practice is to replace the keeper each time the Pro-Torq nut assembly is removed for maintenance purposes.

Step 6:

If the inner tang does not line up with the keyway, back the nut off slightly until it does. Using a small screwdriver, compress and insert the keeper arms, one at a time, into the undercut groove. The orange painted side of the keeper must be facing out

Step 7:

Failure to follow this instruction could cause the wheel to come off and cause bodily injury. Make sure that the keeper tab and keeper arms are fully seated into the undercut groove.

Step 8:

Inspect keyway tang to ensure it does not contact the bottom of the keyway. If contact exists, immediately notify your PRO-TORQ® representative.

Step 9: Acceptable End Play

The dial indicator should be attached to the hub or brake drum with its magnetic base. Adjust the dial indicator so that its plunger is against the end of the spindle with its line of action approximately parallel to the axis of the spindle.

Grasp the wheel or hub assembly at the 3 o’clock and 9 o’clock positions. Push and pull the wheel-end assembly in and out while oscillating the wheel approximately 45 degrees. Stop oscillating the hub so that the dial indicator tip is in the same position as it was before oscillation began. Read the bearing end-play as the total indicator movement.

*Acceptable end-play is .001” – .005”

Please refer to TMC RP 618A “Wheel Bearing Adjustment Procedures”

Agreement for Allowable Standard Repair Times (SRT) for Pro-Torq Inspection Program

The following Terms of Service are effective August 29, 2018:

| BETWEEN: | Owner, Operator, Dealer, Repair Facility (Service Provider) performing the Inspection Procedures |

| AND: | AXN Heavy Duty (Company) 5534 National Turnpike Louisville, KY 40214 |

BILLING AGREEMENT for SRT:

Service Provider is prepared to provide the following professional services to Company.

- A qualified Service Provider will have to precisely follow the INSPECTION PROCEDURE – Pro-Torq Retaining Clips-RevC.pdf.

- For the Inspection Procedure, the Service Provider will charge the allowable rate of:

- Service Provider will fill in all fields on the Trailer Inspection Checklist.pdf and then submit to AXN per the instructions on the checklist, along with the final Service Provider Repair Invoice.

- Bills are payable by Company to Service Provider within 30 days of the receipt date of Invoice.

- Any Questions, or Repairs or Fees OUTSIDE of the scope of Inspection Procedures will need to be discussed with AXN Heavy Duty by emailing inspection@axnheavyduty.com or calling the Support Number at (502) 882-9115.

AXN Heavy Duty

inspection@axnheavyduty.com

502.882.9122

ACTION PLAN: Pro-Torq Retaining Clip (Keeper) Inspection

August 29, 2018 RevC

Loading...

Loading...

Trailer Inspection Checklist – Pro-Torq Snap Ring

08.29.2018-RevC

Loading...

Loading...

Agreement for Allowable Standard Repair Times (SRT) for Pro-Torq Inspection Program

Loading...

Loading...

Manufacturer Notice

Loading...

Loading...

Recall Acknowledgement

September 25, 2018

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- 71" Hubface 58" Spring Center / 5x4.5 Bolt Pattern

- Specs: 2,000 lb Capacity, 1 3/4" Tube | Internal Components: 2k (2000 lb Capacity) Bearing Kit (2 sets), 2k TK Axle Hub- 4 lug Idler, 2k TK Axle Beam - 2k Tube, 2k TK Axle Studs - 1/2"

- How to Measure Your Trailer Axle - Hubface: Measure from one face of hub (where the studs start coming out of hub) to the face of hub on opposite side. Spring Center: Measure from center of one spring seat, to the center of spring seat on opposite side (see image in gallery for more details).

- Fully Assembled High Strength Straight Steel Axle Tube - Underslung: Axle is welded with spring seats on the bottom allows from lower ride height).For optimal usage, use with double eye springs. EZ Lube Design: Removable rubber plug on the hub cap with easy access to a grease-able zerk fitting. Grease your axle without pulling off your whole entire hub.

- Designed for use on Light Duty Trailers: Utility, Boat, Car Haulers, ATV, Lawn & Landscape, Motorcycle, BBQ Pit, Cargo, Enclosed, RV Trailers and more

- 61" Hubface 46" Spring Center / 5x4.5 Bolt Pattern | Specs: 3,500 lbs Idler Trailer Axle (Capacity 3.5K), 5 Lug, Tube: 2 3/8"

- Internal Components: 3.5k (3500 lb Capacity) Bearing Kit, 3.5k TK Axle Hub - 5 lug Brake, 3.5k TK Axle Beam - 3.5k Tube, 3.5k TK Axle Studs - 1/2"

- How to Measure Your Idler Trailer Axle - Hubface: Measure from one face of hub (where the studs start coming out of hub) to the face of hub on opposite side. Spring Center: Measure from center of one spring seat, to the center of spring seat on opposite side (see image in gallery for more details).

- High Strength Straight Steel Axle Tube Construction - Ensures even tire wear and a better highway experience | Underslung - Axle is welded with spring seats on the bottom. Allows for lower ride height. For optimal usage, use with double eye springs. | EZ Lube Design - Removable rubber plug on the hub cap with easy access to a grease-able zerk fitting. Grease your axle without pulling off your whole entire hub.

- Replaces Dexter

, AL-KO, Hayes

, AL-KO, Hayes , and Lippert

, and Lippert Axles. Design for use on Light Duty Trailers: Utility, Boat, Car Haulers, ATV, Lawn & Landscape, Motorcycle, BBQ Pit, Cargo, Enclosed, RV & More

Axles. Design for use on Light Duty Trailers: Utility, Boat, Car Haulers, ATV, Lawn & Landscape, Motorcycle, BBQ Pit, Cargo, Enclosed, RV & More

- All-in-One Bundle: This 3.5K LD Single Axle trailer kit includes everything you need for a quick and easy installation, such as a 3.5k Idler Axle, double eye hanger kit, 4-Leaf Double Eye Springs, and 2 1.75k U-Bolt Kits

- High Strength Construction - The high strength steel axle tube construction ensures a durable and long-lasting performance for small utility trailers, cargo trailers, ATV trailers, and more

- High-Quality Parts - Made with OEM grade trailer axles and suspension, this kit is packed with high-temp axle grease for reliable performance

- Low Ride Height - With an underslung design, the axle is welded with spring seats on the bottom, allowing for a lower ride height and improved stability

- EZ Lube Design - Removable rubber plug allows for easy access to a grease-able zerk fitting, allowing you to grease your axle without having to remove the entire hub

- 2,000 lbs capacity

- Stub axles can be bolted (hardware not included) or welded to trailer frame

- 45 degree downward starting angle

- Perfect item to easily build your own custom motorcycle trailer

- Read product description below for more detailed information.

- Perfect fit for any RV - No matter what type or size of RV you have, our straight idler axle is a perfect match. With a spring center to spring center distance of 58 inches and 25 ¼ inch long springs, it's designed to provide optimum support and stability while on the road.

- Built to last - Rest easy knowing that our axles are made from high-quality materials and are built to withstand the wear and tear of frequent travel. The 5 lug design with a 4 ¼ inch bolt pattern and durable ½ inch lug studs ensure a secure fit for your wheels.

- Easy installation - Don't waste time struggling with complicated equipment. Our straight idler axle comes fully assembled and ready to install on your RV. Just measure, bolt on, and hit the road! No hassle, no fuss.

- Description: This Dual Axle Fender is made of Q235 steel. Most commonly this style of fender is welded to the trailers frame at several points, or to brackets that are welded to the trailers frame. Both sides of this fender are able to be used as a welding surface to protect the tires from road debris or impacted by the equipment. For example, cargo trailer,utility trailer, car hauler

trailer, landscape trailer

trailer, landscape trailer - Size: 10-1/4" Wide x 72-7/8" Long x 13" Tall. Fits Most 13"-15" Tires

- Heavy Duty: Rugged and Tough. Made of 14 Gauge Steel. Built to strict quality control standards

- Surface: Based on the feedback, we added a new electrophoretic surface treatment, effective rust prevention

- Package Included: 2 x Diamond Tread Plate Trailer fenders

- This Trailer Axle Kit (pack of 2) with 4 on 4" Bolt Idler 1" Hub & Round BT8 Spindle .

- Each hub is rated to 1,250 lbs , when used together can support up to 2,000 lbs. This hub fits standard length spindles, not "short spindles" .

- Specifications:Axle Shaft Dia: 1-1/4" Steps down to 1" at Bearings,Axle Shaft Overall Length: 8-3/4",Hub Stud Length: 1-3/16",Stud Size: 7/16",Hub Dia: 5-1/2",C to C Bolt Pattern: - 2-7/8".

- Package Includes:2 x BT8 4-4" Trailer Hub,2 x BT8 1" Trailer Spindle,4 x L44643 Bearing,2 x Cotter Pin,2 x 1" Spindle Nut & Washer,2 x 1-1/4" ID x 2" OD Grease Seal,2 x Dust Cap,10 x Cone Style Lug Nut.

- 100% Brand New Aftermarket Replacement , Made of high quality stainless steel . If you have any question please feel free to contact us , we will reply you in 24 hours .

- Trailer Axle Kits with 4 on 4" Bolt Idler Hub & 1"

- 1,250 lb Hub Capacity, Used On 2,000 lb Axle Shaft 1 Diameter: 1 1/4" Shaft 2 Diameter: 1" Shaft Length: 8 3/4" (4" Long Stub) Hub A Diameter.: 2 1/2" Hub B Diameter: 5 1/2" Bolt Pattern: 4"

- 2) Idler Hub with Lug Nuts, (2) 1" BT8 Round Spindle with Castle Nut, Pin & Washer, (4) Inner/Outer Bearings, (2) Double-lip Grease Seal (1 1/4" I.D. / 2" O.D.), (2) 2" Grease/Dust Cap

- Assembly with 4 on 4" bolt idler hub & 1" round BT8 spindle. Rated to 1,250 lbs. each or 2,000 lbs. for the pair

- 2 X Trailer Idler Hub Kits 5 on 5" for 3500 lbs Trailer Axle Fits 1-1/16'' to 1-3/8" with 2 X #84 Trailer Axle Spindles

- #84 Spindle with a 1.75" Diameter at Biggest end, Overall length: 8.25", Application: 3500 lbs Trailer Axles, Spindle Capacity: 1750 lbs Per Wheel

- The Package Contains 2 pcs 3500 lbs Trailer Axle Spindle, 2 pcs Cotter Pin, 2 pcs Spindle Nut, 2 Spindle Washers,2 pcs 5 on 5" Trailer Hub, 2 pcs L68149 Inner Cone Bearings, 2 pcs L44649 Outer Cone Bearings, 2 pcs 1.719” I.D X 2.565” O.D Grease Seal,2 pcs E Z Lube Grease Cap with Rubber Plugs, 10 pcs Cone Wheel Nuts 1/2”-20 Thread

- RigsNParts Trailer Idler Hub Kits Using Alloy Steel Materials, It Has Superior Corrosion Resistance and Durability.Trailer Hub Packaged in Bubble Boxes, Which can Effectively Avoid Zero Level Collision and Wear During Transportation

- If You Purchase Trailer Hub Spindle Kit That does Not Meet Your Requirements, Please Contact Us in a Timely Manner

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.