| “This site contains affiliate links for which OEMDTC may be compensated” |

June 21, 2019 NHTSA CAMPAIGN NUMBER: 19V484000

Hydraulic Tank Overpressurize and Rupture

If the tank ruptures it may cause hydraulic fluid to spill. The ruptured tank can cause injuries from plastic debris. The spilled hydraulic fluid could be hot which could cause burn injuries. If the vehicle is on the road when the tank ruptures, the tank pieces or spilled hydraulic fluid may cause a road hazard which could increase the risk of a crash.

NHTSA Campaign Number: 19V484

Manufacturer Oshkosh Corporation

Components EQUIPMENT

Potential Number of Units Affected 137

Summary

Oshkosh Corporation (Oshkosh) is recalling certain 2018 McNeilus Bridgemaster V Concrete Mixer

Bridgemaster V Concrete Mixer vehicles previously recalled under 18V-322. The vehicles may have received an incorrect replacement part during the recall remedy. The filler neck check valve may seal the tank too tightly, causing the tank to overpressurize and possibly rupture.

vehicles previously recalled under 18V-322. The vehicles may have received an incorrect replacement part during the recall remedy. The filler neck check valve may seal the tank too tightly, causing the tank to overpressurize and possibly rupture.

Remedy

Oshkosh will notify owners, and instruct owners to inspect the vehicle to determine which filler neck was received and installed as part of 18V-322. If found to be incorrect, dealers will replace the filler neck, free of charge. The recall began August 9, 2019. Owners may contact Oshkosh customer service at 1-888-686-7278.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

SAFETY NOTICE

VSR-TSB-024

NHTSA Campaign Number: 19V-484

Vehicle Safety Recall – Technical Service Bulletin

PROMPT ACTION REQUIRED

| Attention: | McNeilus Product Owner Product Owner |

| Subject: | Bridgemaster V nylon reservoir filler neck replacement |

| Model Affected: | Bridgemaster V 93 |

| Model Years: | 2008-2018 |

| Date: | June 2019 |

Purpose:

McNeilus Truck and Manufacturing, Inc. has been alerted from our supplier that a concern affecting safety exists in some parts that were sent to customers to correct the issue in VSRTSB-018. It is possible that customers may have received the incorrect filler neck part during the initial safety recall for this issue. This bulletin outlines how to determine if you received the incorrect part and how to install the correct part once you have it.

Truck and Manufacturing, Inc. has been alerted from our supplier that a concern affecting safety exists in some parts that were sent to customers to correct the issue in VSRTSB-018. It is possible that customers may have received the incorrect filler neck part during the initial safety recall for this issue. This bulletin outlines how to determine if you received the incorrect part and how to install the correct part once you have it.

As a reminder, VSR-TSB-018 discussed a concern affecting safety that existed in some McNeilus Bridgemaster V vehicles. Changing the filler neck component on certain nylon hydraulic oil reservoirs will improve venting of the reservoir which will help prevent failure/ leaking of the reservoir.

Bridgemaster V vehicles. Changing the filler neck component on certain nylon hydraulic oil reservoirs will improve venting of the reservoir which will help prevent failure/ leaking of the reservoir.

Affected Vehicles:

The affected vehicle population is McNeilus Bridgemaster V mixers with nylon hydraulic oil reservoirs, produced between 2008-2018. Please refer to the list of affected part orders.

Bridgemaster V mixers with nylon hydraulic oil reservoirs, produced between 2008-2018. Please refer to the list of affected part orders.

Time Completion:

Upon receipt of the parts, complete the enclosed Bridgemaster filler neck replacement procedure for each affected unit. The time of accomplishment may vary due to a number of factors; however, the estimated time for completion of the procedure is 1.0 hour under normal circumstances.

Required Action:

Review and verify your ownership of all affected serial numbers of McNeilus vehicles. If McNeilus

vehicles. If McNeilus records indicate that you are the owner of one or more affected units, a Serial Number List is enclosed. Please be reminded that it is a violation of Federal law for you to sell or lease the trucks covered by this notification until this recall has been performed on these vehicles. Substantial civil penalties apply to violations of this law.

records indicate that you are the owner of one or more affected units, a Serial Number List is enclosed. Please be reminded that it is a violation of Federal law for you to sell or lease the trucks covered by this notification until this recall has been performed on these vehicles. Substantial civil penalties apply to violations of this law.

NOTE! Do not use the mixer truck until the correct filler neck has been installed.

Reimbursement of Costs:

Affected units shall be repaired using the customer’s own qualified service technicians – at no cost to the owner. The repairs should take approximately 1.0 hour.

Labor Reimbursement:

In order to receive credit, claims are to be submitted through the normal warranty claim system. Claims must be received within 30 days of the repair. Claims must include the McNeilus serial number of the truck, the customer asset number, and the number of this bulletin.

serial number of the truck, the customer asset number, and the number of this bulletin.

Parts Reimbursement:

Parts and ground shipping will be reimbursed to the customer. Parts necessary for this repair must be ordered from McNeilus Parts at 888-686-7278.

Parts at 888-686-7278.

Claims are to be submitted through the normal warranty claim system. Claims must be received within 30 days of the repair. Claims must include the McNeilus serial number of the truck, the customer asset number, and this bulletin’s number.

serial number of the truck, the customer asset number, and this bulletin’s number.

Contacts:

If you have questions or need further information, please contact a McNeilus National Service Representative at 888-686-7278.

National Service Representative at 888-686-7278.

Enclosures:

Filler neck replacement procedure

| SAFETY NOTICE |

| Perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate. |

| SAFETY NOTICE |

| Use appropriate Personal Protective Equipment (PPE) as required by your company. |

PROCEDURE: Filler neck inspection for correct part replacement

Tools and Equipment Required (Customer to supply own):

- 7/16” wrench

- Hydraulic oil collection container (if needed)

Parts Required (Purchase from McNeilus ):

):

| Item | Part Number | Description | Qty. |

|---|---|---|---|

| 1 | 1570075 | NECK, NYLON RESERVOIR, BREATHER/FILL PORT | 1 |

NOTE! Do not use the mixer truck until the correct filler neck has been installed.

- Place unit on a flat surface, block truck tires, and perform your company’s Lockout/Tagout procedure. If your company does not have a Lockout/Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate.

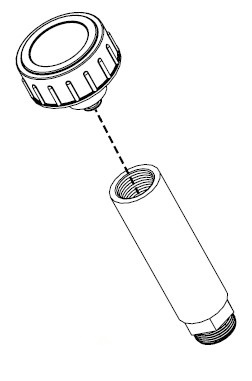

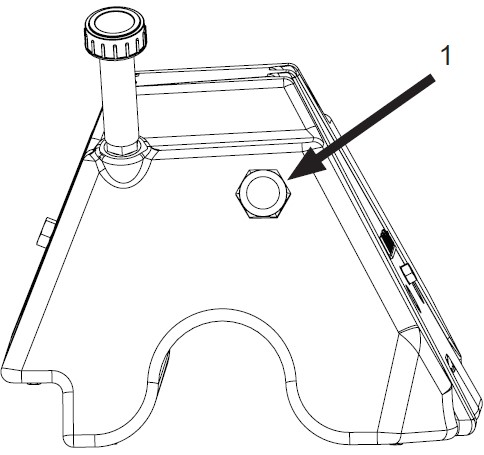

- Unscrew the cap from the installed filler neck (Figure 1). The filler neck itself may be removed from the reservoir using a 7/16” wrench if access to it is hindered.

Figure 1

- Inspect the filler neck.

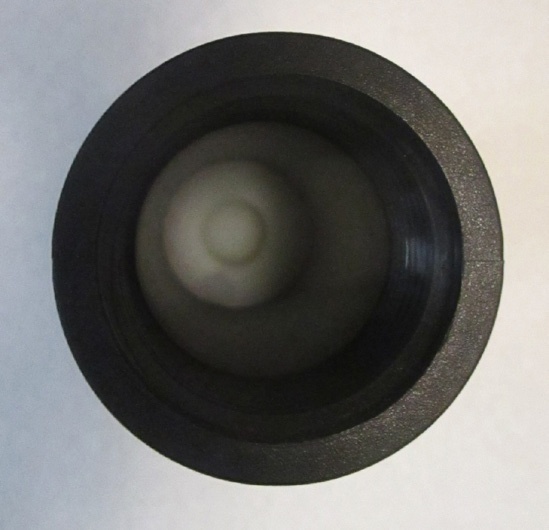

- If it has one visible hole when looking at it from the top (Figure 2), then it is the incorrect Continue with the rest of this bulletin to replace the incorrect part with the correct part.

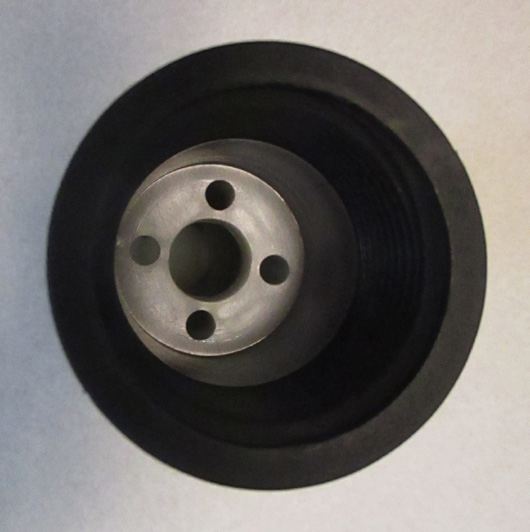

- If it has five visible holes (Figure 3), then it is the correct part and there is no need to replace it.

Screw the cap back onto the filler neck. Proceed to Step 8 to finish the bulletin.

Incorrect Neck – 1 hole

Figure 2

Correct Neck – 5 holes

Figure 3

- Inspect all additional filler neck parts you have on hand that are not installed on a vehicle.

- Order the new, correct filler neck part from McNeilus

by calling 888-686-7278 or visiting streetsmartparts.com. The part number of the filler neck is 1570075. Order as many filler neck parts you need to replace all incorrect filler neck parts.

by calling 888-686-7278 or visiting streetsmartparts.com. The part number of the filler neck is 1570075. Order as many filler neck parts you need to replace all incorrect filler neck parts. - When you have received the correct filler neck, install it according to the following steps.

- Remove the existing filler neck from the reservoir. Keep the existing filler neck to be returned to McNeilus

Warranty following the normal warranty claim process.

Warranty following the normal warranty claim process. - Remove the cap from the existing filler neck.

- Screw the cap onto the new filler neck (Figure 4).

Figure 4

- Ensure the o-ring is installed on the filler neck at the bottom threads.

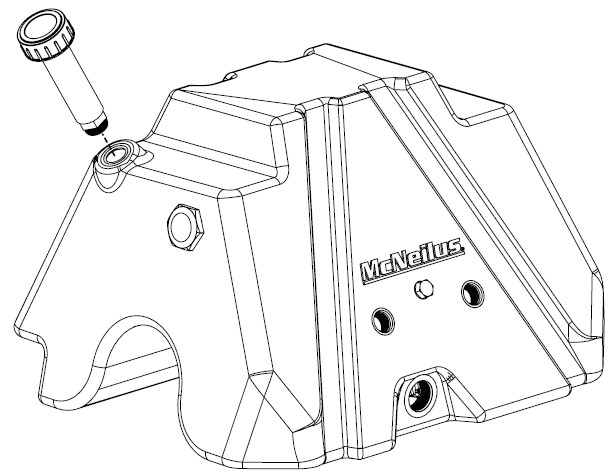

- Screw the filler neck onto the nylon reservoir and use the wrench to tighten the filler neck until snug. Then turn a 1/4 turn past snug. (See Figure 5)

Figure 5

- Remove your company’s Lockout/Tagout procedure. If your company does not have a Lockout/ Tagout procedure, follow OSHA 1910.147 and 1910.146 Confined Space as appropriate.

- Check the oil level in the nylon reservoir sight glass (Figure 6, Item 1). The oil level should be visible in the middle of the sight glass.

- For an accurate oil level reading, the Bridgemaster axle must be in the up position and the chute should be in the down position.

- If the oil level is higher, place an oil collection container under reservoir and drain oil from bottom plugs until the level is visible in the middle of the sight glass. Dispose of oil according to proper regulations.

- If the oil level is lower, refer to the operator’s or service manuals for filling instructions.

Figure 6

- Reference the Mixer Mechanical Seminar and Training Manual (PN 1468111) for information on checking the nitrogen level and the nitrogen cylinder accumulator and filling if necessary. The Mixer Mechanical Seminar and Training Manual may be downloaded from streetsmartparts.com.

- Return the incorrect filler neck part(s) to McNeilus

Warranty by following the normal warranty claim process.

Warranty by following the normal warranty claim process. - The procedure is complete.

- The vehicle can be returned to service.

1 Affected Product

Vehicle

MCNEILUS | BRIDGEMASTER V MIXER | 2018 |

9 Associated Documents

Defect Notice 573 Report

RCLRPT-19V484-6549.PDF 213.478KB

Loading...

Loading...

Recall Acknowledgement

RCAK-19V484-9083.pdf 244.863KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V484-6266.pdf 594.802KB

Loading...

Loading...

Recall Quarterly Report #2, 2019-4

RCLQRT-19V484-8270.PDF 211.226KB

Loading...

Loading...

Recall 573 Report- Amendment 1

RCLRPT-19V484-1181.PDF 213.474KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V484-0659.pdf 594.802KB

Loading...

Loading...

Recall 573 Report- Amendment 2

RCLRPT-19V484-1469.PDF 213.525KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-3

RCLQRT-19V484-6792.PDF 211.122KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-1

RCLQRT-19V484-3467.PDF 211.305KB

Loading...

Loading...

Latest Recalls Documents

- Premium Anti-Wear Protection: Formulated with specially selected anti-wear agents to safeguard modern hydraulic systems.

- Optimal Performance: High viscosity index ensures stable operation across a wide temperature range.

- Extended Service Life: Robust oxidation inhibitors and corrosion protection extend oil life up to 8,000 hours.

- Efficient Air Release: Rapid entrained air release enhances hydraulic system efficiency.

- Anti-Foam Formulation: Anti-foamants minimize foaming for reliable performance.

- Anti-Wear Protection: Designed to reduce wear on hydraulic components, extending equipment lifespan.

- Viscosity: Has a viscosity grade of 32, suitable for moderate temperature operations.

- Temperature Range: Effective in a wide temperature range, maintaining performance in varying conditions.

- Oxidation Stability: Offers good resistance to oxidation, helping to prevent sludge and varnish formation.

- Corrosion Inhibition: Contains additives that protect against rust and corrosion in metal components.

- 6,000 HOUR SEVERE SERVICE - Extremely long life fluid, with very long oxidation life. 3 times the life of most other fluids.

- ANTI-WEAR BOOSTER PACK

- Contains a built-in severe service anti-wear booster pack

- Contains a built-in severe service anti-wear booster pack . Three times the zinc of most other hydraulic oils.

. Three times the zinc of most other hydraulic oils. - HIGH VISCOSITY INDEX - Ultimate durability in all types of service. It does not overheat, prevents hydraulic cavitation, maintains fluid seals on pistons, and does not shear.

- ZERO FOAMING - Virtually zero foaming on all industry-standard tests and ultra-rapid air release.

- SAVES 50%- 80% on fluid costs annually vs regular or economy hydraulic oils.

- Premium Quality: AW 46 hydraulic oil is a premium quality product with anti-wear and anti-foam properties.

- Rust Inhibition: It contains rust oxidation and corrosion inhibitors for enhanced protection.

- Versatile Application: Suitable for use in hydraulic systems requiring an ISO VG 46 viscosity grade oil.

- Reliable Performance: Formulated to provide reliable performance in hydraulic equipment.

- Convenient Packaging: Available in a 5 gallon/18.9 liter container for easy handling and storage.

- Multi-Purpose Fluid: Recommended for hydraulic, final drive, transmission, differential, and wet brake systems in Kubota equipment

- Superior Performance: Improved transmission performance and protection at extreme temperatures

- Friction Characteristics: Enables smoother start-off, drive control, and PTO connection

- Corrosion Resistance: Provides superior corrosion resistance and efficient filterability

- Improved Efficiency: Reduces power loss, leading to improved transmission efficiency

- Reduces the operating temperature of hydraulic systems

- Conditions old seals and O-rings to stop and prevent future leaks

- Well suited for use in equipment with wet brakes

- Removes varnish and restores pressure for more efficient operation

- Compatible with both synthetic and conventional hydraulic fluids

- Anti-Wear Properties: Formulated to provide superior protection against wear, extending the life of hydraulic components.

- Viscosity Grade: Has a viscosity rating of 46, making it suitable for a wider range of operating temperatures than AW 32.

- Temperature Performance: Effective in high-temperature environments, maintaining performance and fluidity.

- Oxidation Resistance: Enhanced stability to prevent oxidation and degradation, reducing the risk of sludge formation.

- Corrosion Protection: Contains additives that inhibit rust and corrosion, protecting metal surfaces in hydraulic systems.

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.