| “This site contains affiliate links for which OEMDTC may be compensated” |

March 25, 2020 NHTSA CAMPAIGN NUMBER: 20V181000

Fender Liner may Damage Brake Line

Loss of brake fluid can extend the distance needed to stop the vehicle, increasing the risk of a crash.

can extend the distance needed to stop the vehicle, increasing the risk of a crash.

NHTSA Campaign Number: 20V181

Manufacturer Daimler Vans USA, LLC

USA, LLC

Components SERVICE BRAKES, AIR, STRUCTURE

Potential Number of Units Affected 48,775

Summary

Daimler Vans USA, LLC (DVUSA) is recalling certain 2019 Freightliner

USA, LLC (DVUSA) is recalling certain 2019 Freightliner Sprinter

Sprinter and Mercedes-Benz

and Mercedes-Benz Sprinter

Sprinter vehicles. The rear part of the fender liner on the front axle may contact and chafe the brake hose

vehicles. The rear part of the fender liner on the front axle may contact and chafe the brake hose , possibly resulting in a loss of brake fluid

, possibly resulting in a loss of brake fluid .

.

Remedy

DVUSA will notify owners, and Mercedes-Benz or Freightliner

or Freightliner Sprinter

Sprinter dealers will inspect and replace the brake hoses, as necessary. Additionally, the fender liners will be modified. All services will be performed free of charge. The recall began May 8, 2020. Owners may contact DVUSA customer service at 1-877-762-8267. DVUSA’s number for this recall is VS3BRADVER.

dealers will inspect and replace the brake hoses, as necessary. Additionally, the fender liners will be modified. All services will be performed free of charge. The recall began May 8, 2020. Owners may contact DVUSA customer service at 1-877-762-8267. DVUSA’s number for this recall is VS3BRADVER.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check for Daimler Vans Recalls

TO: Mercedes-Benz and Freightliner and Freightliner Dealer Principals, General Managers, Sales Managers, Service Managers, Parts Managers Dealer Principals, General Managers, Sales Managers, Service Managers, Parts Managers | FROM: Anthony Washington, Department Manager, Regulations and Certifications |

| RE: Recall Campaign Notification Model 907 (Sprinter  ) )Model Years 2019 Front Axle Brake Hose  | DATE: May 15, 2020 |

IMPORTANT CAMPAIGN INFORMATION

| Campaign | Campaign Desc. : | Front Axle Brake Hose | |

| 2020040023 | VS3BRADVER | ||

This is to notify you of the upcoming Recall Campaign concerning the front fender liners on approximately 48,804 MY19 Mercedes-Benz and Freightliner and Freightliner Sprinter Sprinter vans. The recall campaign will be visible on the www.safercar.gov website and may generate questions from customers. All affected VINs will be flagged as “Open” in VMI. vans. The recall campaign will be visible on the www.safercar.gov website and may generate questions from customers. All affected VINs will be flagged as “Open” in VMI. | |||

| Background | |||

| Issue | Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz and Freightliner and Freightliner vans, has determined that on certain Sprinter vans, has determined that on certain Sprinter vehicles the rear part of the fender liner on the front axle could contact and chafe the brake hose vehicles the rear part of the fender liner on the front axle could contact and chafe the brake hose . If the distance between the fender liner and the brake hose . If the distance between the fender liner and the brake hose is not sufficient, the front wheel suspension could contact and chafe the brake hose is not sufficient, the front wheel suspension could contact and chafe the brake hose , which could lead to the loss of brake fluid , which could lead to the loss of brake fluid . Over time, if the operator ignores the brake fluid . Over time, if the operator ignores the brake fluid warning indicator and continues to operate the vehicle until the brake fluid warning indicator and continues to operate the vehicle until the brake fluid empties, this may increase the stopping distance and increase the risk of a crash. empties, this may increase the stopping distance and increase the risk of a crash. | ||

| What We’re Doing | An authorized Mercedes-Benz or Freightliner or Freightliner Sprinter Sprinter dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side. dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side. | ||

| Parts | Parts are available. | ||

| Vehicles Affected | |||

| Vehicle Model Year(s) | Model Year 2019 | ||

| Vehicle Model | Sprinter , VS30 / Platform 907 , VS30 / Platform 907 | ||

| Vehicle Populations | |||

| Total Recall | 48,804 | ||

| Dealer Inventory | 5,974 | ||

| Given this notice, it is a violation of Federal Law for a dealer to sell or lease any new MY19 Sprinter vehicles in dealer inventory covered by this notification until the vehicle has been repaired.

Loaner and demonstrator vehicles may continue to be driven, but must not be retailed until repaired. Additionally, given this notice, it is a violation of Federal Law for rental companies to rent new MY19 Sprinter vehicles covered by this notification until the vehicle has been repaired. | |||

| Next Steps/Notes | |||

| Customer Notification Timeline | An owner notification letter will be mailed in late May, 2020. | ||

| AOMS/SOMS | AOMs – This recall may generate questions from your dealers. Please forward this notice to your dealers ASAP. | ||

| Rental Fleet Partners | This recall may affect vehicles in your fleet. Please contact your respective DVUSA fleet representative for further information and next steps. For repairs, please contact your preferred DVUSA dealer. | ||

| While we regret any inconvenience this may cause, we are determined to maintain a high level of vehicle quality and customer satisfaction. | |||

Campaign No. 2020040023, May 2020

| TO: | ALL MERCEDES-BENZ CENTERS CENTERS |

| SUBJECT: | Model 907 (Sprinter ), Model Year 2019 ), Model Year 2019Front Axle Brake Hose  |

Mercedes-Benz AG (“MBAG”), the manufacturer of Mercedes-Benz

AG (“MBAG”), the manufacturer of Mercedes-Benz and Freightliner

and Freightliner vans, has determined that on certain Sprinter

vans, has determined that on certain Sprinter vehicles the rear part of the fender liner on the front axle could contact and chafe the brake hose

vehicles the rear part of the fender liner on the front axle could contact and chafe the brake hose . If the distance between the fender liner and the brake hose

. If the distance between the fender liner and the brake hose is not sufficient, the front wheel suspension could contact and chafe the brake hose

is not sufficient, the front wheel suspension could contact and chafe the brake hose , which could lead to the loss of brake fluid

, which could lead to the loss of brake fluid . Over time, if the operator ignores the brake fluid

. Over time, if the operator ignores the brake fluid warning indicator and continues to operate the vehicle until the brake fluid

warning indicator and continues to operate the vehicle until the brake fluid empties, this may increase the stopping distance and increase the risk of a crash. An authorized Mercedes-Benz

empties, this may increase the stopping distance and increase the risk of a crash. An authorized Mercedes-Benz or Freightliner

or Freightliner Sprinter

Sprinter dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side.

dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side.

Prior to performing this Recall Campaign:

- Please check VMI to determine if the vehicle is involved in the Campaign and if it has been previouslyrepaired.

- Please review the entire Recall Campaign bulletin and follow the repair procedure exactly as

Please note that Recall Campaigns do not expire and may also be performed on a vehicle with a vehicle status indicator.

Approximately 48,804 vehicles are involved.

Order No. V-RC-2020040023

Please use only work instructions

SM88.10-D-0019SG,

SM88.10-D-0019-02SG, and

SM88.10-D-0019-03SG

when processing the vehicles.

Operation no. of the operation texts or standard texts and flat rates

| Op. no. | Operation text | Time (hrs.) | Acc. no. |

| 02 1773 | Operations: Check front fender liner and adjacent component parts | 0.2 | 42 960 87 |

| 02 1796 | Operations: Move vehicle onto vehicle lift for rework | 0.2 | 42 960 87 |

| 02 1777 | Operations: Replace front section of a front fender liner ….. (vehicle raised) | 0.3 | 42 960 87 |

| 02 1804 | Operations: Replace rear section of a front fender liner ….. (vehicle raised) | 0.3 | 42 960 87 |

| 02 1805 | Operations: Replace front and rear section of front fender liner ….. (vehicle raised) | 0.5 | 42 960 87 |

| 02 1808 | Operations: Replace 2 front sections of front fender liners ….. (vehicle raised) | 0.5 | 42 960 87 |

| 02 1809 | Operations: Replace 2 rear sections of front fender liner ….. (vehicle raised) | 0.4 | 42 960 87 |

| 02 1750 | Operations: Adapt one section of a front fender liner ….. (vehicle raised) | 0.2 | 42 960 87 |

| 02 1803 | Operations: Adapt both sections of a front fender liner ….. (vehicle raised) | 0.2 | 42 960 87 |

| 02 1775 | Operations: Replace brake hose of front axle (after check) of front axle (after check) | 0.4 | 42 960 87 |

| 02 1776 | Operations: Replace 2 brake hoses of front axle (after check) | 0.5 | 42 960 87 |

| 02 1806 | Operations: Bleed hydraulic brake system (brake hoses replaced) | 0.4 | 42 960 87 |

| 02 3282 | Operations: Remove underfloor paneling (vehicle on vehicle lift) | 0.2 | 42 960 87 |

| Important! |

| The following operation steps are to be performed on the right and left side of the vehicle. |

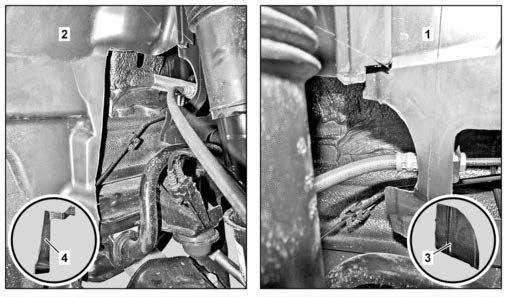

D88.10-A003-79 | |

| 1 Front section of fender liner | a Dimension (approx. 20 mm) |

| 2 Rear section on fender liner | b Dimension (approx. 5 mm) |

| Danger | Risk of death caused by vehicle slipping or toppling off of the lifting platform. | Align vehicle between vehicle lift columns and position the four support plates at the vehicle lift support points specified by the vehicle manufacturer. | AS00.00-Z-0010-01A |

| Caution | Risk of injury caused by scraping or cutting body parts on sharp vehicle parts | Always wear protective gloves when working on or near sharp and non-deburred vehicle parts.

Deburr repair panels. | AS00.00-Z-0017-01A |

| Check | |||

| 1 | Check, whether the vehicle is affected by the measure. | Affected vehicles: Subsequently modify front fender liner (code:

VS3BRADVER, acc. no.: 42 960 87) Model 907.### 1P as of 000485 up to 136806 Affected vehicles: Subsequently modify front fender liner (code: VS3BRADVER, acc. no.: 42 960 87) Model 907.### 1P as of 136807 up to 225641 Model 907.### 2P as of 000484 up to 225373 Affected vehicles: Subsequently modify front fender liner (code: VS3BRADVER, acc. no.: 42 960 87) Model 907.### 1E as of 179972 up to 188412 Model 907.### 1N as of 000264 up to 088619 Model 907.### 1T as of 000306 up to 022132 Model 907.### 2N as of 000967 up to 088558 Only the entry in the “Extended VEGA Application” (EVA) system in the “Current” tab is decisive for authorized Mercedes-Benz | SM88.10-D-0019-01AAA

SM88.10-D-0019-01AAB

SM88.10-D-0019-01AAC

|

| 2 | Check distances between rear sections of fender liner (2) and stabilizer. | To check the distances, the vehicle’s suspension must be in the compressed condition.

The distance between the rear section of the fender liner (2) and the stabilizer should be approx. 5 mm. If a rear section of the fender liner (2) is in front of the stabilizer or the distance is too small, ↓ adapt rear section of fender liner (2) (as of operation step 8). If a rear section of the fender liner (2) is deformed, damaged or the fastening points are not OK, ↓ replace rear section of fender liner (2) (as of operation step 6). | |

| 3 | Check distances between front sections of fender liners (1) and brake hoses. | To check the distances, the vehicle’s suspension must be in the compressed condition.

The distance between the front section of the fender liner (1) and the front brake hose If the distance between a brake hose ↓ adapt front section of fender liner (1) (as of operation step 8). | |

| 4 | Check front and rear sections of fender liners (1, 2) for damage and tight seating. | Adjacent components (brake hoses) must also be checked for damage and, if necessary, cleaned

using a rag before visual inspection. i Check the following points: ‑ damage to nuts – damage to mounting holes – damage to sections of fender liner – damage to brake hoses If no damage or chafe marks are found and the distances to the brake hoses and the stabilizer are sufficient, ↓ end the measure. If damage is visible on a section of the front fender liner, ↓ replace respective section of fender liner (as of operation step 6). If damage or chafe marks are present on the front brake hoses, ↓ replace affected front brake hose | AR42.10-D-0026TS |

| Replace | |||

| 5

Topical note | Raise vehicle.

Special instructions for lifting and supporting vehicle | AH00.60-N-0100-01TS

AR00.60-D-1000-04TS | |

| 6 | Replace front section of front fender liner (1). | Depending on the findings.

If front section of fender liner (1) is to be replaced, ↓ adapt front section of fender liner (1) before installation. | AR88.10-D-1322TS

SM88.10-D-0019-03SG |

| 7 | Replace rear section of front fender liner (2). | Depending on the findings.

If rear section of fender liner (2) is to be replaced, ↓ adapt rear section of fender liner (2) before installation. | AR88.10-D-1321TS

SM88.10-D-0019-03SG |

| Adjust | |||

| 8 | Subsequently adapt front fender liner in installed state. | If front or rear sections of fender liners (1, 2) were not replaced. | SM88.10-D-0019-02SG |

| 9 | Lower vehicle. |

Parts ordering note

| Part no. | Designation | Quantity |

| A 907 684 27 02 | Front section of left front fender liner | As Needed |

| A 907 684 28 02 | Front section of right front fender liner | As Needed |

| A 907 684 02 00 | Rear section of left front fender liner | As Needed |

| A 907 684 03 00 | Rear section of right front fender liner | As Needed |

| A 002 990 53 50 | Nuts | As Needed |

| A 000 990 54 92 | Expansion rivet | As Needed |

| A 907 428 42 00 | Front brake hose | As Needed |

| A 907 428 29 00 | Front brake hose (4×4 Vehicles only) (4×4 Vehicles only) | As Needed |

Note: The expected parts replacement rate is approximately 1% for the fender liners and approximately 5% of the brake hoses of the affected population.

| SM88.10-D-0019-02SG | Subsequently modify front fender liner in installed state (code: VS3BRADVER, acc. no.: 42 960 87) | ||

| Danger | Risk of death caused by vehicle slipping or toppling off of the lifting platform. | Align vehicle between vehicle lift columns and position the four support plates at the vehicle lift support points specified by the vehicle manufacturer. | AS00.00-Z-0010-01A |

| Caution | Risk of injury caused by scraping or cutting body parts on sharp vehicle parts | Always wear protective gloves when working on or near sharp and non-deburred vehicle parts.

Deburr repair panels. | AS00.00-Z-0017-01A |

Model 907

The following operation steps are shown on the right side of the vehicle and must be performed in the same way on the left side of the vehicle.

1 Turn steering.

Turn steering to left if right fender liner is to be processed.

Turn steering to right if left fender liner is to be processed.

Adapt front section of fender liner (1) i

2 Mark separation lines on front section of Clean area on front section of fender liner fender liner (1) as shown. (1) using a rag.

Observe dimension (C).

Clean area on front section of fender liner (1) using a rag.

D88.10-A001-75

Adapt front section of fender liner (1)

3 Detach front section of fender liner (1).

To do so, separate front section of fender liner (1) at separation line using a suitable tool (e.g. carpet blade).

The remaining piece (3) can be reused as a template.

Make sure that no adjacent components are damaged when cutting out.

If components or anti-corrosion protection have been damaged,

↓

replace corresponding vehicle parts or repair anti-corrosion protection.

4 Use suitable tool to deburr edges.

Adapt rear section of fender liner (2)

5 Mark separation lines on rear section of fender liner (2) as shown.

Observe dimensions (A, B).

Clean area on rear section of fender liner (2) using a rag.

D88.10-A001-75

Adapt rear section of fender liner (2)

6 Detach rear section of fender liner (2).

To do so, separate rear section of fender liner (2) at separation line using a suitable tool (e.g. carpet blade).

The remaining piece (4) can be reused as a template.

Make sure that no adjacent components are damaged when cutting out.

If components or anti-corrosion protection have been damaged,

↓

replace corresponding vehicle parts or repair anti-corrosion protection.

7 Use suitable tool to deburr edges.

| SM88.10-D-0019-03SG | Subsequently modify front fender liner in removed state (code: VS3BRADVER, acc. no.: 42 960 87) | ||

| Caution | Risk of injury caused by scraping or cutting body parts on sharp vehicle parts | Always wear protective gloves when working on or near sharp and non-deburred vehicle parts.

Deburr repair panels. | AS00.00-Z-0017-01A |

Model 907

The following operation steps are shown on components on the right side of the vehicle and must be performed in the same way on components on the left side of the vehicle.

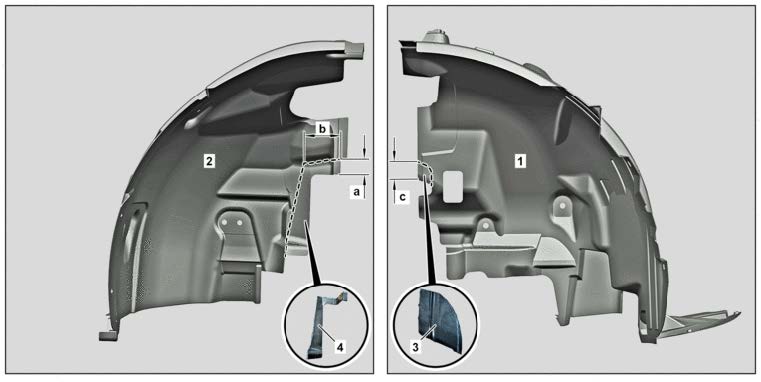

D88.10-A002-79 | |

| 1 Front section of fender liner | b Dimension (70 mm) |

| 2 Rear section on fender liner | c Dimension (14 mm) |

| a Dimension (21 mm) | |

Adapt front section of fender liner (1)

1 Mark separation lines on front section of fender liner (1) as shown. i

Observe dimension (C).

2 Detach front section of fender liner (1).

To do so, separate front section of fender liner (1) at separation line using a suitable tool (e.g. carpet blade).

The remaining piece (3) can be reused as a template.

3 Use suitable tool to deburr edges.

Adapt rear section of fender liner (2)

4 Mark separation lines on rear section of fender liner (2) as shown.

Observe dimensions (A, B).

5 Detach rear section of fender liner (2).

To do so, separate rear section of fender liner (2) at separation line using a suitable tool (e.g. carpet blade).

The remaining piece (4) can be reused as a template.

6 Use suitable tool to deburr edges.

IMPORTANT SAFETY RECALL #2020040023

This notice applies to your vehicle, VIN:

Front Axle Brake Hose

NHTSA Recall #20V181

May, 2020

2020040023

|

Dear Freightliner Sprinter

Sprinter Owner or Lessee,

Owner or Lessee,

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act.

Mercedes-Benz AG (“MBAG”), the manufacturer of Freightliner

AG (“MBAG”), the manufacturer of Freightliner Sprinter

Sprinter vans, has decided that a defect which relates to motor vehicle safety exists in certain Model Year 2019 Freightliner

vans, has decided that a defect which relates to motor vehicle safety exists in certain Model Year 2019 Freightliner Sprinter

Sprinter vehicles. Our records indicate that your vehicle is included in the affected population of vehicles.

vehicles. Our records indicate that your vehicle is included in the affected population of vehicles.

| What is the CONCERN? | MBAG determined that on certain Freightliner Sprinter Sprinter vehicles vans, the rear part of the fender liner on the front axle could contact and chafe the brake hose vehicles vans, the rear part of the fender liner on the front axle could contact and chafe the brake hose . If the distance between the fender liner and the brake hose . If the distance between the fender liner and the brake hose is not sufficient, the front wheel suspension could contact and chafe the brake hose is not sufficient, the front wheel suspension could contact and chafe the brake hose , which could lead to the loss of brake fluid , which could lead to the loss of brake fluid . Over time, if the operator ignores the brake fluid . Over time, if the operator ignores the brake fluid warning indicator and continues to operate the vehicle until the brake fluid warning indicator and continues to operate the vehicle until the brake fluid empties, this may increase the stopping distance and increase the risk of a crash. empties, this may increase the stopping distance and increase the risk of a crash. |

| What will your DEALER DO? | An authorized Mercedes-Benz Sprinter Sprinter dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side. This service will be provided free of charge. While the minimum repair time is approximately 4 hours, your dealer can provide you with a better estimate of the overall time for this service visit. As a matter of normal service process, an authorized Freightliner dealer will check the condition and clearance of the brake hoses and, if necessary, to replace them. Additionally, the corresponding fender liner will be modified accordingly on the respective side. This service will be provided free of charge. While the minimum repair time is approximately 4 hours, your dealer can provide you with a better estimate of the overall time for this service visit. As a matter of normal service process, an authorized Freightliner dealer will also check for other repair measures which might be applicable to your vehicle and this may increase the required working time. You will not be charged for other service or repairs unless so requested. dealer will also check for other repair measures which might be applicable to your vehicle and this may increase the required working time. You will not be charged for other service or repairs unless so requested. |

Schedule an appointment immediately at your preferred authorized Freightliner Sprinter

Sprinter Dealer. See www.freightlinersprinterusa.com/freightliner/owners-resources/recall for the Dealer Locator. Please mention you are scheduling an appointment to check the brake hoses under Recall Campaign # 2020040023. You may be asked for your 17digit Vehicle Identification Number (VIN) which for your convenience is located above your name at the top of this letter.

Dealer. See www.freightlinersprinterusa.com/freightliner/owners-resources/recall for the Dealer Locator. Please mention you are scheduling an appointment to check the brake hoses under Recall Campaign # 2020040023. You may be asked for your 17digit Vehicle Identification Number (VIN) which for your convenience is located above your name at the top of this letter.

We encourage you to sign up for recall alerts at www.nhtsa.gov/alerts. In the event that you are no longer the vehicle owner, or have had a change of address, please complete the reverse side and return the updated information in the enclosed envelope.

If this is a leased vehicle and the lessor and registered owner receive this notice, please forward this information by first class mail to the lessee within 10 business days to comply with Federal Regulations.

Should you have any questions difficulty regarding this Recall Campaign, please contact an authorized Freightliner Sprinter

Sprinter dealer. If for any reason a dealer is unable to remedy your situation, we are always happy to hear from you. Please contact us at 1-877-762-8267.

dealer. If for any reason a dealer is unable to remedy your situation, we are always happy to hear from you. Please contact us at 1-877-762-8267.

If an authorized Freightliner dealer for any reason is unable to remedy the situation without charge, or within a reasonable amount of time, pursuant to law 49 U.S.C. Chapter 301, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue, S.E., Washington, D.C. 20590 or call the toll-free Auto Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153); or go to https://www.safercar.gov.

dealer for any reason is unable to remedy the situation without charge, or within a reasonable amount of time, pursuant to law 49 U.S.C. Chapter 301, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue, S.E., Washington, D.C. 20590 or call the toll-free Auto Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153); or go to https://www.safercar.gov.

We apologize for any inconvenience this situation may cause you, but your safety is of utmost concern to Freightliner .

.

Sincerely,

Daimler Vans USA, LLC

USA, LLC

One Mercedes-Benz Drive

Drive

Sandy Springs, GA 30328

Phone (770) 705-0600

IMPORTANT VIN:

If for any reason YOU NO LONGER OWN THIS VEHICLE OR have a CHANGE OF ADDRESS, please COMPLETE THE SECTION BELOW, place in the ENCLOSED ENVELOPE, and DROP IN ANY MAIL BOX. If possible, provide the name and address of the present owner so that we may contact them.

9 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

FREIGHTLINER | SPRINTER 1500 1500 | 2019 |

FREIGHTLINER | SPRINTER 2500 2500 | 2019 |

FREIGHTLINER | SPRINTER 3500 3500 | 2019 |

FREIGHTLINER | SPRINTER 4500 4500 | 2019 |

MERCEDES BENZ BENZ | SPRINTER (VS30) (VS30) | 2019 |

MERCEDES-BENZ | SPRINTER 1500 1500 | 2019 |

MERCEDES-BENZ | SPRINTER 2500 2500 | 2019 |

MERCEDES-BENZ | SPRINTER 3500 3500 | 2019 |

MERCEDES-BENZ | SPRINTER 4500 4500 | 2019 |

11 Associated Documents

Recall Acknowledgement

RCAK-20V181-2106.pdf 245.141KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-20V181-6190.PDF 214.421KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-20V181-1972.pdf 188.738KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

RCMN-20V181-6692.pdf 1653.948KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-20V181-2532.pdf 108.952KB

Loading...

Loading...

Recall 573 Report- Amendment 2

RCLRPT-20V181-1699.PDF 216.375KB

Loading...

Loading...

Recall 573 Report-Amendment 1

RCLRPT-20V181-4979.PDF 215.518KB

Loading...

Loading...

Recall 573 Report- AMENDMENT 3

RCLRPT-20V181-6779.PDF 215.666KB

Loading...

Loading...

Recall Quarterly Report #1, 2020-2

RCLQRT-20V181-0561.PDF 211.143KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-4

RCLQRT-20V181-9948.PDF 211.33KB

Loading...

Loading...

Recall Quarterly Report #2, 2020-3

RCLQRT-20V181-7752.PDF 211.245KB

Loading...

Loading...

Latest Recalls Documents

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS

, disc and drum brake systems

, disc and drum brake systems - Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100 percent longer than DOT 3, 50 percent longer than DOT 4, and 10 percent longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid

has a recommended change interval of 2 years. The recommended change interval for Bosch

has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

ESI6 is 3 years.

- The 336⁰F wet boil point and 521⁰F dry boil point exceeds common characteristics for DOT 4 brake fluids

- Provides corrosion protection in brake components

- Matches needs of all DOT 4 manufacturer recommendations

- Compatible with all DOT 3 and DOT 4 applications

- Helps provide protection against brake failure from vapor lock

- Helps prevent corrosion in brake system

- Works with all brake system requiring DOT 3 fluids

- Exceeds federal motor vehicle safety standard No. 116

- Meets SAE spec. J1703.

- Premium DOT 3 Brake Fluid

has a minimum boiling point of 450°F

has a minimum boiling point of 450°F - Meets and exceeds DOT 3 and all other Federal and SAE specifications and standards for motor vehicle brake fluids

- Mixes with all DOT 3 approved brake fluids

- Designed for use in disc, drum and ABS brake systems

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid

boiling and vapor lock

boiling and vapor lock - Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

- Maintains proper movement for safe, effective stopping performance

- Helps deliver a quieter braking system

- Produces smoother pedal travel

- Provides longer brake life and performance

- Install Wagner with total confidence

- An exclusive European formula with an exceptionally high boiling point and superior anti-vapor lock characteristics

- Superior braking during arduous conditions like racing and rallying

- Typical wet boiling point is 270deg. C

Last update on 2025-04-17 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.