| “This site contains affiliate links for which OEMDTC may be compensated” |

March 25, 2020 NHTSA CAMPAIGN NUMBER: 20V182000

Engine output shaft bearing failure could cause a sudden loss of power, increasing the risk of a crash.

NHTSA Campaign Number: 20V182

Manufacturer Indian Motorcycle Company

Motorcycle Company

Components ENGINE

Potential Number of Units Affected 616

Summary

Indian Motorcycle Company (Indian

Motorcycle Company (Indian ) is recalling certain 2020 Challenger

) is recalling certain 2020 Challenger motorcycles. The engine output shaft bearing may not have been sufficiently lubricated during assembly, possibly resulting in bearing failure at very low mileage.

motorcycles. The engine output shaft bearing may not have been sufficiently lubricated during assembly, possibly resulting in bearing failure at very low mileage.

Remedy

Indian will notify owners, and dealers will lubricate the output shaft bearings on motorcycles with less than 50 miles on the odometer, free of charge. Motorcycles with greater than 50 miles will not require a repair, and can either be inspected by a dealer, or the owner can self-report the odometer reading directly to Indian

will notify owners, and dealers will lubricate the output shaft bearings on motorcycles with less than 50 miles on the odometer, free of charge. Motorcycles with greater than 50 miles will not require a repair, and can either be inspected by a dealer, or the owner can self-report the odometer reading directly to Indian . The recall began April 9, 2020. Owners may contact Indian

. The recall began April 9, 2020. Owners may contact Indian customer service at 1-877-204-3697. Indian

customer service at 1-877-204-3697. Indian ’s number for this recall is I-20-02. Note: Owners with an odometer reading of less than 50 miles are advised to not operate their motorcycle until it is repaired.

’s number for this recall is I-20-02. Note: Owners with an odometer reading of less than 50 miles are advised to not operate their motorcycle until it is repaired.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check for Indian Motorcycle Recalls

| Release Date: April 02, 2020 |

SAFETY BULLETIN |

| Communication #: I-20-02-A/B

Model Year(s): 2020 | |

|

— Confidential and Proprietary — | |

VERSION: R01 (April 02, 2020)

IMPORTANT STOP SALE SAFETY NOTICE!

Stop selling affected vehicles immediately until the repair procedure has been completed on affected units at your dealership. Federal law prohibits the sale of products subject to a recall. Selling such products could subject the seller to substantial penalties.

IMPORTANT

If you are working with a printed copy, please verify you have the most current version of this document.

SUBJECT: OUTPUT SHAFT BEARING PURPOSE

Indian Motorcycle has identified a potential concern with the engine output shaft bearing on a small number of model year 2020 Indian

Motorcycle has identified a potential concern with the engine output shaft bearing on a small number of model year 2020 Indian Motorcycles (108 c.i.). Early model year 2020 production units may not have had adequate initial bearing lubrication during assembly which, combined with other factors, may lead to bearing failure at very low mileage. Operating a motorcycle that was assembled with an improperly lubricated output shaft bearing may result in unintended or sudden deceleration which may increase the risk of a crash.

Motorcycles (108 c.i.). Early model year 2020 production units may not have had adequate initial bearing lubrication during assembly which, combined with other factors, may lead to bearing failure at very low mileage. Operating a motorcycle that was assembled with an improperly lubricated output shaft bearing may result in unintended or sudden deceleration which may increase the risk of a crash.

To address this concern, Indian Motorcycle is instructing dealers to inspect odometers and perform the repair procedure on any motorcycles with less than 50 miles (80 km).

Motorcycle is instructing dealers to inspect odometers and perform the repair procedure on any motorcycles with less than 50 miles (80 km).

AFFECTED MODELS

| MODELYEAR | MODELS | VEHICLE IDENTIFICATION NUMBER RANGE |

| 2020 | Indian Challenger Challenger | Reference Unit Inquiry on the dealer website or the Service Communications list on the STOP site to lookup affected VINs. |

CUSTOMER NOTIFICATION

Dealers are required to review their sales records and contact customers to discuss this Bulletin. Indian Motorcycle will notify consumers by mail to inform them of the concern and how to proceed based on their odometer reading.

Motorcycle will notify consumers by mail to inform them of the concern and how to proceed based on their odometer reading.

Consumers with an odometer reading of 50 miles (80 km) or more will be given the option to submit an electronic web-form with mileage verification to complete the I-20-02-A inspection. No further action will be required.

If a consumer has more than 50 miles (80 km) on their odometer but does not wish to self-report using the electronic form, they may have the inspection and bulletin completed by a dealer. Consumers with an odometer reading of 49 miles (79km) or less will be asked to have their motorcycle transported to a dealer for completion of I-20-02-B. Instructions for dealer reimbursement of travel/transport are included in this Bulletin. Dealers are required to correct any affected units in their inventory.

WARRANTY CLAIM PARTS INFORMATION

| ODOMETER INSPECTION – 50+ MILES (80+ KM) | |

| Bulletin # | I-20-02-A |

| Claim Type | SB (Service Bulletin) |

| Labor Allowance | 0.2 hours (12 minutes) |

| Part Number / Description | 0000541 (QTY 1) Bulletin Misc Labor |

| Parts Availability | NA |

Universityof Polaris Video Training Required Video Training Required | NO |

| ODOMETER INSPECTION – LESS THAN 50 MILES (80 KM) – & OUTPUT SHAFT BEARING LUBRICATION | |

| Bulletin # | I-20-02-B |

| Claim Type | SB (Service Bulletin) |

| Labor Allowance | 1.3 hours (78 minutes) |

| Part Number / Description | 0000541 (QTY 1) Bulletin Misc Labor |

| Parts Availability | NA |

Universityof Polaris Video Training Required Video Training Required | Yes1 |

1Polaris requires two people from a dealership to be certified before warranty claims may be processed.

requires two people from a dealership to be certified before warranty claims may be processed.

US & CANADA TRANSPORT & MOBILE SERVICE REIMBURSEMENT

Polaris will authorize travel or transport up to 1.0 hour of labor to perform the bulletin. Wholegood stock vehicles are not eligible for travel / transport coverage reimbursement. Polaris

will authorize travel or transport up to 1.0 hour of labor to perform the bulletin. Wholegood stock vehicles are not eligible for travel / transport coverage reimbursement. Polaris recommends that dealers work with vehicle owners to determine the best solution for their situation. To obtain travel / transport reimbursement, enter the actual labor time up to 1.0 hour, into the Travel Hours or Travel Minutes on the bulletin claim.

recommends that dealers work with vehicle owners to determine the best solution for their situation. To obtain travel / transport reimbursement, enter the actual labor time up to 1.0 hour, into the Travel Hours or Travel Minutes on the bulletin claim.

ACCESSORY LABOR

Polaris will cover labor for the removal and installation of accessories required to complete the bulletin work. Follow the steps below to obtain reimbursement.

will cover labor for the removal and installation of accessories required to complete the bulletin work. Follow the steps below to obtain reimbursement.

- Start a new Ask Polaris Case, Service &Warranty Question > Authorization: In Warranty or Polaris

ESC or Authorization: Out of Warranty.

ESC or Authorization: Out of Warranty. - Enter your contact information and VIN, along with miles and hours into the applicable fields.

- Enter Indian

Motorcycle® I-20-02 in the CONCERN and CAUSE fields. In the CORRECTION field, enter “ACCESSORY REMOVAL AND INSTALLATION”.

Motorcycle® I-20-02 in the CONCERN and CAUSE fields. In the CORRECTION field, enter “ACCESSORY REMOVAL AND INSTALLATION”. - Enter warranty fail codes 127/277/132.

- Add part 0000541, quantity 1.

- Attach photos of the vehicle and accessories sufficient to support the labor time requested.

- Submit the case to Polaris

.

.

BULLETIN CONTACT LIST & SCHEDULING TOOL

A scheduling tool is available for dealers to keep a record of customers contacted and scheduled for this bulletin. This optional tool provides visibility for your dealership and will be helpful to track the status of scheduled service. For more information, log in to https://www.universityofpolaris.com.

COVERAGE PERIOD

Coverage will begin on April 02, 2020. This bulletin has no expiration date.

UNIVERSITY OF POLARIS TRAINING REQUIREMENT

TRAINING REQUIREMENT

Each member of your service department team must complete the training on University of Polaris prior to completing ANY work, or submitting ANY warranty claim for this Bulletin. You must complete the entire course on University of Polaris

prior to completing ANY work, or submitting ANY warranty claim for this Bulletin. You must complete the entire course on University of Polaris in order to get credit. www.universityofpolaris.com

in order to get credit. www.universityofpolaris.com

FEEDBACK FORM

A feedback form has been created for the technician to provide Polaris with an overall satisfaction rating for the instructions, provide comments on your experience or upload pictures/video. This feedback form is viewable on a mobile device by scanning the QR code or by clicking HERE if viewing this document electronically.

with an overall satisfaction rating for the instructions, provide comments on your experience or upload pictures/video. This feedback form is viewable on a mobile device by scanning the QR code or by clicking HERE if viewing this document electronically.

I-20-02-A ODOMETER READING

- Power on the motorcycle.

- Check the mileage on the odometer.

- If the odometer reads MORE than 50 miles (80 km), the repair procedure does not need to be performed. File Bulletin I-20-02-A

- If the odometer reads LESS than 50 miles (80 km), proceed to I-20-02-B to complete the repair procedure.

I-20-02-B OUTPUT SHAFT BEARING LUBRICATION

TOOLS REQUIRED:

- 1/4”, 1 7/8” socket

- 3/8”ratchet, 3/8” flex joint

- 10” extension

- 8 mm, 15 mm, 27 mm sockets

- 6 mm, 8 mm allen

- 8 mm wrench

- in-lb and ft-lb torque wrenches

- 3 mL of clean full-synthetic, 15W60 Indian

Motorcycle engine oil

Motorcycle engine oil - Magnet

- Syringe (10 mL slip-tip or similar)

- Loctite 262 (red)

- Motorcycle Jack

- Gates 507C Sonic Tension Meter or equivalent, OR Belt Tension Gauge PV-43532

OUTPUT SHAFT BEARING ACCESS, DISASSEMBLY

1. Park the motorcycle on a lift table with the wheel clamped in a wheel vise.

2. Turn the ignition off.

3. Remove the saddlebags.

4. Remove three clamps and rear head pipe heat shield.

WARNING

Engine and exhaust components get hot and remain hot for a period of time after the engine is stopped. Wear insulated protective clothing or wait for components to cool sufficiently before working on the machine.

IMPORTANT

Note orientation of exhaust clamps for reinstallation.

5. Remove right-hand passenger foot peg.

6. Pull straight out to remove upper side cover. Remove lower side cover fastener and remove lower side cover.

IMPORTANT

When removing the upper side cover, pull the cover straight out to avoid damage.

7. Remove left muffler.

8. Remove fasteners and drive sprocket cover.

9. Remove fasteners and locking plate from drive sprocket.

10. Place the motorcycle in gear or apply the rear brake.

11. Using a 1 7/8” socket, loosen and remove the drive sprocket nut.

12. Remove two fasteners and lower heat shield.

13. Loosen rear axle nut and belt adjuster nuts to allow slack in the belt.

14. Jack up rear of the motorcycle.

15. Remove belt from drive sprocket.

16. Working from driven sprocket, pull drive belt back far enough to contact the swingarm pivot.

17. Remove drive sprocket from output shaft.

18. Using a magnet, work around the diameter of the spacer and remove from output shaft.

NOTICE

If spacer cannot be removed with a magnet, an adjustable pliers can be used with a shop rag around the spacer to protect the sealing.

19. Fill syringe with 3 mL of Indian Motorcycle engine oil.

Motorcycle engine oil.

NOTICE

The use of a plastic syringe to inject oil into the bearing gallery is the preferred method. However, It is acceptable to use an alternate tool that allows the transfer of 3mL clean oil into the gallery without damaging the oil seal.

20. In the gap between the output shaft and the seal, inject all 3 mL of the engine oil into the bearing gallery.

NOTICE

Small amounts of extra oil may spill over the lower seal lip. Make sure to clean any spilled oil prior to assembly

ASSEMBLY

1. Install the spacer to the output shaft.

IMPORTANT

Make sure the chamfer is inward toward the engine during installation.

2. Install the drive sprocket to the output shaft.

3. Using a soft wire brush, clean output shaft threads and nut threads.

4. Apply Loctite 262 to the output shaft threads. Install the drive sprocket nut.

5. Install the belt onto the sprocket.

6. With the motorcycle in gear and rear brake applied. Torque drive sprocket nut t to specification.

TORQUE

Drive Sprocket Nut: 165 ft-lbs (224 N·m)

7. Install locking plate to the drive sprocket. Torque fasteners to specification.

TORQUE

Lock Plate Fastener: 84 in-lbs (10 N·m)

8. Rotate the drive sprocket three full revolutions first clockwise, then counter-clockwise to distribute the oil in the bearing.

IMPORTANT

Ensure the drive sprocket spins smoothly and quietly, indicating the bearing is in good condition.

IMPORTANT — AUDIT STEP

A secondary dealer representative must spin the drive sprocket to ensure it spins smoothly and quietly.

9. Install lower heat shield. Torque fasteners to specification.

TORQUE

Drive Sprocket Cover Fastener: 84 in-lbs (10 N·m)

10. Install lower side panel and fastener. Torque fasteners to specification.

TORQUE

Side Panel Fasteners: 18 ft-lbs (24 N·m)

11. Install upper side panel.

12. Install drive sprocket cover and fasteners. Torque fasteners to specification.

TORQUE

Drive Sprocket Cover Fastener: 84 in-lbs (10 N·m)

13. Install passenger foot peg. Torque fastener to specification.

TORQUE

Foot Peg Fastener: 35 ft-lbs (47 N·m)

14. Install the rear head pipe heat shield. Torque clamps q to specification.

TORQUE

Heat Shield Clamp: 31 in-lbs (3 N·m)

15. Perform the following procedures in the MAINTENANCE chapter of the Service Manual.

- DRIVE BELTADJUSTMENT

- DRIVE BELT TENSION MEASUREMENT

16. Install left muffler and saddlebags.

17. Field Test the motorcycle to verify proper operation.

18. File Bulletin I-20-02-B

IMPORTANT SAFETY NOTICE

This notice applies to your vehicle

Recall Campaign: 20V-182

Subject: 2020 Challenger Output Shaft Bearing

Output Shaft Bearing

PLEASE READ IMMEDIATELY

VIN: I-20-02

First Name Last Name

Address

City, State ZIP

Dear Indian Motorcycle Owner,

Motorcycle Owner,

This notice is sent to you in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Indian Motorcycle has decided that a defect which relates to motor vehicle safety exists in certain 2020 Challenger

Motorcycle has decided that a defect which relates to motor vehicle safety exists in certain 2020 Challenger motorcycles (108 c.i.) This is to inform you that your vehicle could contain a defect that could affect the safety of a person. Our records show you have purchased an affected vehicle.

motorcycles (108 c.i.) This is to inform you that your vehicle could contain a defect that could affect the safety of a person. Our records show you have purchased an affected vehicle.

The reason for this notice:

Indian Motorcycle has identified a potential concern with the engine output shaft bearing on some of model year 2020 Indian

Motorcycle has identified a potential concern with the engine output shaft bearing on some of model year 2020 Indian Challenger

Challenger Motorcycles (108 c.i.). Early model year 2020 production units may not have had adequate initial bearing lubrication during assembly which, combined with other factors, may lead to bearing failure at very low mileage. Operating a motorcycle that was assembled with an improperly lubricated output shaft bearing may result in unintended or sudden loss of power which may increase the risk of a crash. If your vehicle has already been ridden 50 or greater miles it has demonstrated that it was built with adequate assembly lubrication.

Motorcycles (108 c.i.). Early model year 2020 production units may not have had adequate initial bearing lubrication during assembly which, combined with other factors, may lead to bearing failure at very low mileage. Operating a motorcycle that was assembled with an improperly lubricated output shaft bearing may result in unintended or sudden loss of power which may increase the risk of a crash. If your vehicle has already been ridden 50 or greater miles it has demonstrated that it was built with adequate assembly lubrication.

What you should do:

OPTION 1: Your vehicle has 50 miles (80 km) or greater on the odometer:

You may choose to inspect the odometer and report mileage to Indian Motorcycle.

Motorcycle.

Enter the URL information https://www.polaris.com/en-us/i-20-02/ into a web browser or scan the QR code to complete the required information. Providing this information will mark completion of this safety recall, and ensure your vehicle’s records are up to date. If you are uncomfortable with self-reporting, your dealer can also complete the odometer inspection for you.

OPTION 2: Your vehicle has less than 50 miles (80 km) on the odometer:

Contact your local Indian Motorcycle dealer to arrange transport and repair of your motorcycle prior to operation. Do not attempt repairs yourself. Repairs must only be done by an authorized Indian

Motorcycle dealer to arrange transport and repair of your motorcycle prior to operation. Do not attempt repairs yourself. Repairs must only be done by an authorized Indian Motorcycle dealer. This repair should take approximately 60 minutes. When making contact with your dealer, discuss dealership hours, their schedule, and how long they will need to keep your vehicle.

Motorcycle dealer. This repair should take approximately 60 minutes. When making contact with your dealer, discuss dealership hours, their schedule, and how long they will need to keep your vehicle.

What your dealership will do:

If you select Option 1, Indian Motorcycle will update your vehicle’s records to reflect this safety bulletin as complete.

Motorcycle will update your vehicle’s records to reflect this safety bulletin as complete.

If you select Option 2, your Indian Motorcycle dealer has been authorized to complete transport, inspection, and repair, free of charge. Your dealership will apply direct lubrication to the affected bearing on vehicles that have less than 50 miles (80 km) on the odometer. This work will be performed by your dealer at no cost to you.

Motorcycle dealer has been authorized to complete transport, inspection, and repair, free of charge. Your dealership will apply direct lubrication to the affected bearing on vehicles that have less than 50 miles (80 km) on the odometer. This work will be performed by your dealer at no cost to you.

This notice was mailed to you according to our most current registration information. If you no longer own this vehicle, or if some of the contact information in this notice is incorrect, please contact your dealer to complete a transfer of ownership. Federal law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within 10 days.

If you need assistance contacting or locating an Indian Motorcycle dealer, or if you have questions your Indian

Motorcycle dealer, or if you have questions your Indian Motorcycle dealer is not able to address, contact our Indian

Motorcycle dealer is not able to address, contact our Indian Motorcycle Owner Connections Department at 1-877-204-3697, scan the QR code, or go to https://www.indianmotorcycle.com/en-us/self-help/.

Motorcycle Owner Connections Department at 1-877-204-3697, scan the QR code, or go to https://www.indianmotorcycle.com/en-us/self-help/.

If you believe that Indian Motorcycle has failed to remedy this defect without charge or is unable to do so within a reasonable time, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE., Washington, D.C. 20590; or call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153); or on the web go to www.safercar.gov.

Motorcycle has failed to remedy this defect without charge or is unable to do so within a reasonable time, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue SE., Washington, D.C. 20590; or call the toll-free Vehicle Safety Hotline at 1-888-327-4236 (TTY: 1-800-424-9153); or on the web go to www.safercar.gov.

We apologize for this inconvenience and assure you that we are committed to customer satisfaction and providing world-class products for riders to enjoy.

Sincerely,

Indian Motorcycle Company

Motorcycle Company

For the latest updates to this safety recall, or to check if your vehicle is part of another safety recall, scan the QR code, or go to www.polaris.com/en-us/on-road-recalls/.

1 Affected Product

Vehicle

| MAKE | MODEL | YEAR |

INDIAN | CHALLENGER | 2020 |

9 Associated Documents

Defect Notice 573 Report

RCLRPT-20V182-8900.PDF 214.29KB

Loading...

Loading...

Recall Acknowledgement

RCAK-20V182-9671.pdf 244.877KB

Loading...

Loading...

Recall 573 Report – Amendment 1

RCLRPT-20V182-7474.PDF 216.414KB

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-20V182-0730.pdf 349.498KB

Loading...

Loading...

Recall 573 Report – Amendment 2

RCLRPT-20V182-5503.PDF 215.804KB

Loading...

Loading...

Recall Quarterly Report #1, 2020-2

RCLQRT-20V182-5900.PDF 211.222KB

Loading...

Loading...

Recall Quarterly Report #2, 2020-3

RCLQRT-20V182-4447.PDF 211.222KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-4

RCLQRT-20V182-1377.PDF 211.309KB

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-20V182-3893.pdf 8653.882KB

Loading...

Loading...

Latest Recalls Documents

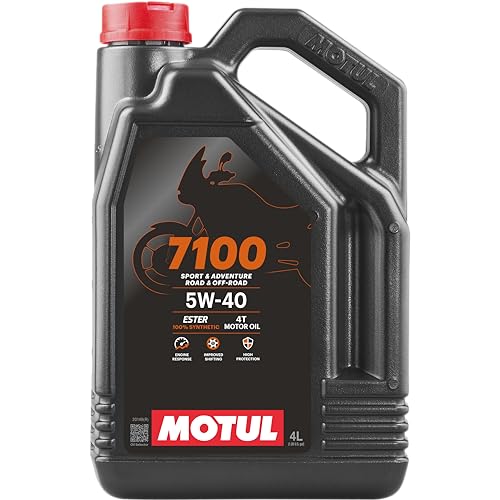

- Formulated with Trizone technology to protect all 3 critical zones: engine, clutch and gearbox

- Race derived technology for maximum engine acceleration

- Extreme high temperature air-cooled performance and water-cooled engine performance

- Excellent shear stability to prevent viscosity breakdown

- Exceeds API SL and JASO MA-2

- 100% Synthetic Ester

- Formulated To Meet The Latest Manufacturers' Specifications

- Improved High Temperature Deposit Protection And Sludge Control

- Ensures Optimum Clutch Performance At Start-Up, Acceleration, And Full Speed

- Standards: Ape Sn, Jasso Ma2

- Optimal lubrication in all operating conditions, ensures low oil consumption

- Very high shear and ageing stability, highest levels of wear protection

- Tested and approved for catalytic converters, optimal engine cleanliness

- Ideally suited for wet clutches

- Specifications and Approvals: API, SM, ACEA A3-04, JASO, MA2

- Full synthetic 5W-40 diesel engine oil with Triple Protection Plus technology protects against wear, deposits, and oil breakdown

- Improved wear performance with significantly increased level of protection against harmful engine wear (compared to previous generation API CJ-4 engine oils)

- Enhanced fuel economy capability of 1.5% without compromising engine protection or durability (compared to 15W-40 oils)

- Multi-functional dispersant additives provide an enhanced level of protection against the effects of soot, dirt, and other contaminants

- Resists breakdown by heat to provide continuous protection throughout the service interval, and also provides improved low-temperature flow compared to conventional 15W-40 oils

- The information below is per-pack only

- ADVANCED PROTECTION IN EUROPEAN VEHICLES agains the four main causes of engine breakdown: wear friction heat and deposits

- EXTRA WEAR PROTECTION vs. industry and OEM standards with advanced anti-wear additives

- SUPERIOR PERFORMANCE FOR EUROPEAN gasoline and diesel engines

- EXCEPTIONAL HIGH/LOW TEMPERATURE PROTECTION defends your engine no matter the climate or driving conditions

- 100% Synthetic Double Ester

- Designed for highly modified engines

- Electrochemical bonding to metal parts

- Up to 5x higher film strength

- 0% shear loss on Bosch

ASTM D6278 test

ASTM D6278 test

Last update on 2025-04-18 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.