| “This site contains affiliate links for which OEMDTC may be compensated” |

Campaign No. 2020040003, March 2021

| TO: | ALL MERCEDES-BENZ and FREIGHTLINER and FREIGHTLINER SPRINTER SPRINTER CENTERS CENTERS |

| SUBJECT: | Model 906 (Sprinter ) )Model Year 2015 Modification to the emissions control system |

Daimler Vans USA, LLC (“DVUSA”) and Mercedes-Benz

USA, LLC (“DVUSA”) and Mercedes-Benz USA, LLC (“MBUSA”) are performing an emissions campaign on certain 906 Sprinter

USA, LLC (“MBUSA”) are performing an emissions campaign on certain 906 Sprinter vehicles in order to modify to the vehicles’ emissions control system. EPA and CARB have approved this emissions modification for these MY15 Sprinter

vehicles in order to modify to the vehicles’ emissions control system. EPA and CARB have approved this emissions modification for these MY15 Sprinter (Model 906) vehicles. An authorized Mercedes-Benz

(Model 906) vehicles. An authorized Mercedes-Benz or Freightliner

or Freightliner Sprinter

Sprinter dealer will replace certain emissions control system components and update certain software in the affected vehicles at no cost to the owner of the vehicle.

dealer will replace certain emissions control system components and update certain software in the affected vehicles at no cost to the owner of the vehicle.

Prior to performing this Emissions Campaign:

- Please check VMI to determine if the vehicle is involved in the emissions modification campaign and if it has been previously repaired. Always Check VMI for any open campaigns, and perform accordingly.

- Please review the entire Emissions Campaign bulletin and follow the repair procedure exactly as described.

Approximately 837 vehicles are involved.

Order No. V-RC-2020040003

This bulletin has been created and maintained in accordance with MBUSA-SLP S423QH001, Document and Data Control, and MBUSA-SLP S424HH001, Control of Quality Records.

Emissions Campaign 2020040003

Warranty Information

| Damage Code | Operation No. | Time | Operation Text |

| Denial of AEM | |||

| 49 10N 01 | use operations for labor performed | up to 2 hr | Diagnosis time for pre-inspection if client declines to reverse non-compliant modifications |

| Perform AEM | |||

| 07 970 97 | 02 1212 | 1.4 hr | Perform work package for field measure |

| Additional: Mobile AEM at customer location | |||

| 21 812 00 | 00 9627 | +50% | Mobile AEM Labor surcharge |

| sublet | $75 travel allowance | ||

| Additional: Mobile AEM at customer location requiring overnight accommodation | |||

| 21 813 00 | 00 9627 | +50% | Mobile AEM Labor surcharge |

| sublet | $100 travel allowance | ||

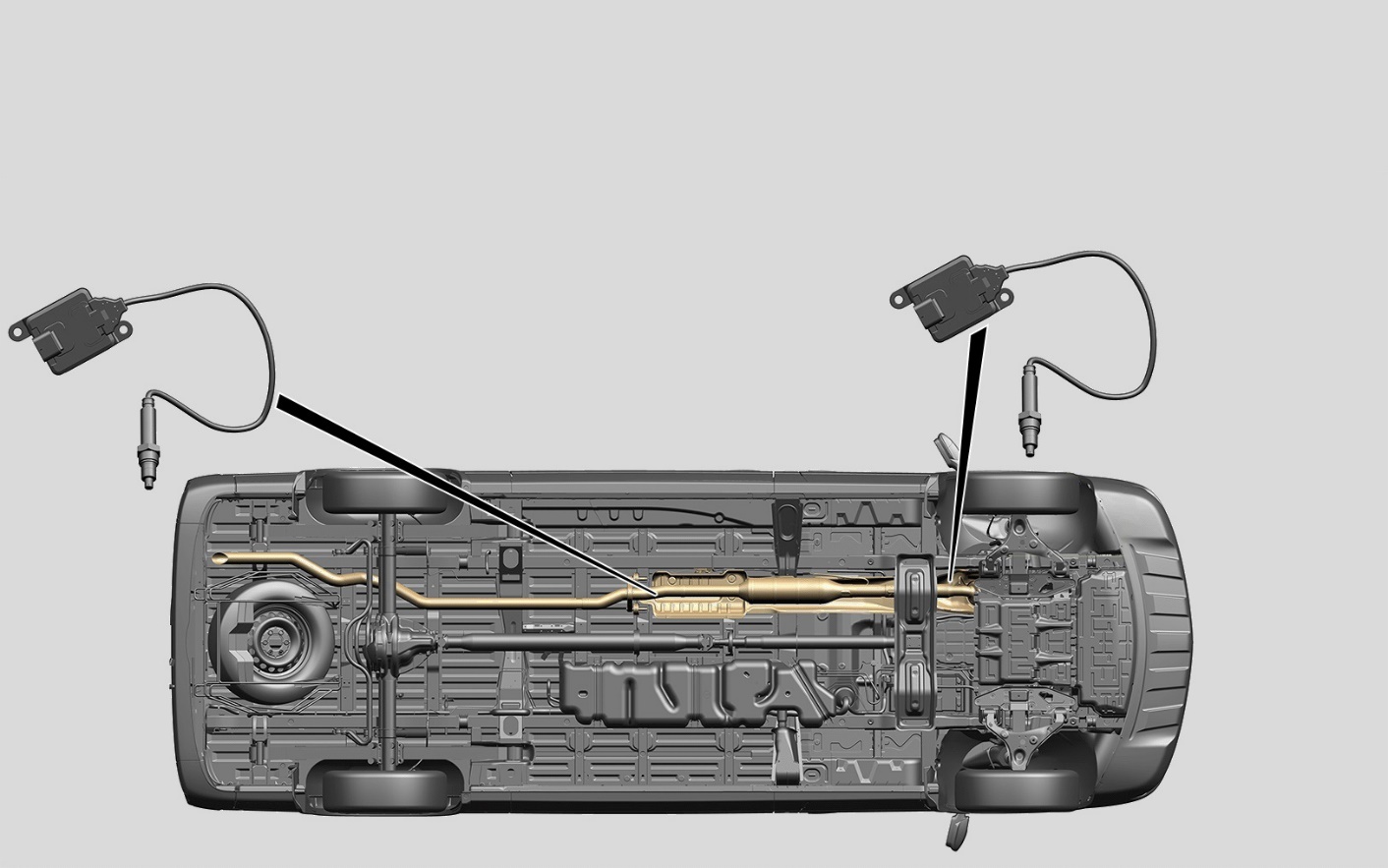

Parts Overview

| NOx sensor downstream of SCR catalytic converter | NOx sensor upstream of SCR catalytic converter |

| |

Reference last page for complete list of parts to perform AEM

Scope of Work Outline

| Read and follow all pages of work instructions completely! | Page: |

| 1. Safety Notes | 4-18 |

| 2. Lifting and Ramps | 19-21 |

| 3. Initial Quick Test | 22-28 |

|

a. Upload print-out to paperless pXD b. Evaluate pre-existing faults (see Pre-Inspection Guide below) | |

| 4. Pre-Inspection Special Procedure | 29-32 |

| a. Includes visual inspection of Exhaust Aftertreatment system (see Pre-Inspection Guide below) | |

| 5. Replacement of AEM parts | 33-38 |

|

a. NOx Sensor Upstream of SCR Catalytic Converter b. NOx Sensor Downstream of SCR Catalytic Converter | |

| 6. Execution of AEM Special Procedure | 39-50 |

|

a. Includes guided steps to Replace CDI and Update Software of CDI, ETC, IC, and SCR b. Fill-out and Install AEM Label c. Result Report to verify successful completion of all AEM steps i. Upload print-out to paperless pXD | |

| 7. Final Quick Test | 51-56 |

|

a. Upload print-out to paperless pXD b. Erase stored faults caused by the workshop | |

| 8. Parts List | 57 |

Pre-Inspection Guide

- Pre-existing fault codes causing a Check Engine Light (CEL):

a. If component causing fault will be replaced as part of the AEM:

i. Perform AEM – No additional action is needed

b. If component causing fault will be covered by the AEM Extended Warranty:

i. Perform AEM

ii. Perform repair of pre-existing fault

iii. Submit AEM Extended Warranty claims on a separate Repair Order after AEM claim is submitted

c. If component causing fault will not be replaced as part of AEM and not covered by AEM Extended Warranty:

i. Provide client with repair estimate, advise client AEM will not resolve Check Engine Light (CEL)

ii. Document on Repair Order if client approves or declines repairs

iii. Perform AEM regardless if client approves or declines repairs

d. A list of AEM Extended Warranty covered components is available in: XENTRY / CDI / Special Procedures / Exhaust Aftertreatment Service Measure / Extended Warranty

- Non-Compliant Alterations to the Exhaust Aftertreatment system found during the visual Pre-Inspection:

a. Document all non-compliant alterations to the Exhaust Aftertreatment system on the Repair Order

b. If altered component(s) will be replaced as part of the AEM:

i. Perform AEM

c. If altered component(s) inhibit AEM installation or will sustainably affect the operation of the AEM:

i. Provide client with a repair estimate to reverse non-compliant alterations

1. If client approves repairs:

a. Reverse non-compliant alterations

b. Perform AEM

2. If client refuses repairs:

a. Do not perform AEM – Vehicle ineligible

b. Claim ‘Denial of AEM’ damage code and labor ops for diagnosis time performed

- If technical assistance is needed, create a PTSS case

Replacement parts 2020040004

| Part No. | Designation | Quantity |

| A 642 905 19 00 85 | NOx Sensor package | 1 |

| A 220 546 18 43 | Mounting Tab | 1 |

| A 000 994 32 11 | Lock Pin | 4 |

| A 007 997 56 90 | Cable Tie (with holding clip) | 2 |

| N 000000 003477 | Nut Fastener | 4 |

| A 000 584 93 13 | APPROVED EMISSION MODIFICATION LABEL | 1 |

SEOCONTENT-START

Campaign No. 2020040003, March 2021

TO: ALL MERCEDES-BENZ and FREIGHTLINER

and FREIGHTLINER SPRINTER

SPRINTER CENTERS

CENTERS

SUBJECT: Model 906 (Sprinter )

)

Model Year 2015

Modification to the emissions control system

Daimler Vans USA, LLC (“DVUSA”) and Mercedes-Benz

USA, LLC (“DVUSA”) and Mercedes-Benz USA, LLC (“MBUSA”) are performing an

USA, LLC (“MBUSA”) are performing an

emissions campaign on certain 906 Sprinter vehicles in order to modify to the vehicles’ emissions control

vehicles in order to modify to the vehicles’ emissions control

system. EPA and CARB have approved this emissions modification for these MY15 Sprinter (Model

(Model

906) vehicles. An authorized Mercedes-Benz or Freightliner

or Freightliner Sprinter

Sprinter dealer will replace certain

dealer will replace certain

emissions control system components and update certain software in the affected vehicles at no cost to

the owner of the vehicle.

Prior to performing this Emissions Campaign:

• Please check VMI to determine if the vehicle is involved in the emissions modification campaign and

if it has been previously repaired. Always Check VMI for any open campaigns, and perform

accordingly.

• Please review the entire Emissions Campaign bulletin and follow the repair procedure exactly as

described.

Approximately 837 vehicles are involved.

Order No. V-RC-2020040003

This bulletin has been created and maintained in accordance with MBUSA-SLP S423QH001, Document and Data

Control, and MBUSA-SLP S424HH001, Control of Quality Records.

Emissions Campaign 2020040003

o Model: 906 Sprinter

o Model Year: 2015 4×4

o Engine: 6-Cylinder Diesel (OM 642)

Warranty Information

Damage Code Operation No. Time Operation Text

Denial of AEM

49 10N 01 use operations for

labor performed

up to 2 hr Diagnosis time for pre-inspection if client declines

to reverse non-compliant modifications

Perform AEM

07 970 97 02 1212 1.4 hr Perform work package for field measure

Additional: Mobile AEM at customer location

21 812 00 00 9627 +50% Mobile AEM Labor surcharge

sublet $75 travel allowance

Additional: Mobile AEM at customer location requiring overnight accommodation

21 813 00 00 9627 +50% Mobile AEM Labor surcharge

sublet $100 travel allowance

Parts Overview

Reference last page for complete list of parts to perform AEM

NOx sensor upstream of

SCR catalytic converter

NOx sensor downstream

of SCR catalytic converter

a Emissions Campaign 2020040003

1

Scope of Work Outline

Read and follow all pages of work instructions completely! Page:

1. Safety Notes 4-18

2. Lifting and Ramps 19-21

3. Initial Quick Test 22-28

a. Upload print-out to paperless pXD

b. Evaluate pre-existing faults (see Pre-Inspection Guide below)

4. Pre-Inspection Special Procedure 29-32

a. Includes visual inspection of Exhaust Aftertreatment system (see Pre-Inspection Guide below)

5. Replacement of AEM parts 33-38

a. NOx Sensor Upstream of SCR Catalytic Converter

b. NOx Sensor Downstream of SCR Catalytic Converter

6. Execution of AEM Special Procedure 39-50

a. Includes guided steps: Software updates of CDI, ETC, IC, and SCR

b. Fill-out and Install AEM Label

c. Result Report to verify successful completion of all AEM steps

i. Upload print-out to paperless pXD

7. Final Quick Test 51-56

a. Upload print-out to paperless pXD

b. Erase stored faults caused by the workshop

8. Parts List 57

Pre-Inspection Guide

1. Pre-existing fault codes causing a Check Engine Light (CEL):

a. If component causing fault will be replaced as part of the AEM:

i. Perform AEM – No additional action is needed

b. If component causing fault will be covered by the AEM Extended Warranty:

i. Perform AEM

ii. Perform repair of pre-existing fault

iii. Submit AEM Extended Warranty claims on a separate Repair Order after AEM claim is submitted

c. If component causing fault will not be replaced as part of AEM and not covered by AEM Extended Warranty:

i. Provide client with repair estimate, advise client AEM will not resolve Check Engine Light (CEL)

ii. Document on Repair Order if client approves or declines repairs

iii. Perform AEM regardless if client approves or declines repairs

d. A list of AEM Extended Warranty covered components is available in: XENTRY / CDI / Special Procedures /

Exhaust Aftertreatment Service Measure / Extended Warranty

2. Non-Compliant Alterations to the Exhaust Aftertreatment system found during the visual Pre-Inspection:

a. Document all non-compliant alterations to the Exhaust Aftertreatment system on the Repair Order

b. If altered component(s) will be replaced as part of the AEM:

i. Perform AEM

c. If altered component(s) inhibit AEM installation or will sustainably affect the operation of the AEM:

i. Provide client with a repair estimate to reverse non-compliant alterations

1. If client approves repairs:

a. Reverse non-compliant alterations

b. Perform AEM

2. If client refuses repairs:

a. Do not perform AEM – Vehicle ineligible

b. Claim ‘Denial of AEM’ damage code and labor ops for diagnosis time performed

3. If technical assistance is needed, create a PTSS case

a Emissions Campaign 2020040003

2

AEM installation Videos

Exemplary videos of the AEM installation are available via the following:

o XENTRY Workshop (XiW) / VAN / Emissions Modification Program

o Scan the QR code below with a mobile device and log-in with your XENTRY credentials

a Emissions Campaign 2020040003

3

????????????????????????????????????????????????????????????????????????????????????????????????????????

Risk of injury. Skin or eye

injuries may result when

handling hot or glowing objects.

Wear protective gloves,

protective clothing and safety

glasses, if necessary.

aWarning

Risk of injury

Contact with hot or glowing objects without suitable

protective clothing causes severe burns to skin and eyes.

When glowing objects come into contact with water, they

produce hot steam or cause the water to splash, which can

cause serious burns to skin or eyes.

If hot or glowing objects come into contact with unprotected

skin or eyes, they can cause serious and even permanent

injuries.

i

There is a risk of fire when glowing objects come into

contact with combustible material.

Safety precautions/instructions

• Wear protective clothing, safety glasses and heatresistant

gloves.

• Only transport hot or glowing objects with suitable aids.

• Avoid the formation of sparks and contact with

combustible material when handling glowing objects.

First aid measures

• Treat affected areas of skin with plenty of cold water

and cover with sterile dressings.

• Consult a physician immediately.

Risk of injury. Skin or eye injuries may result when handling hot or glowing objects.

a Emissions Campaign 2020040003

4

Risk of accident from vehicle

starting off by itself when engine

running. Risk of injury (bruises

and burns) resulting from

working on the engine while it is

being started or when it is

running.

Secure vehicle to prevent it from

starting off by itself. Wear

closed and snug-fitting work

clothes. Do not touch hot or

rotating parts.

aWarning

Potential risks

Risk of accident

Caused by the vehicle starting off by itself during the

starting procedure

(e.g. during compression test) due to engaged gear or

with the engine running and vehicles with automatic

transmission due to selector lever position “P” or

“N” not being engaged (except for vehicles that do not

have selector lever position “P”).

Risk of injury

Severe injuries can be caused by freely rotating parts in

the area of the running engine.

Because the engine heats up when operating, serious

burns can be caused by touching unshielded parts.

Safety instructions/precautions

• In general, only work on a running engine when it is

absolutely necessary.

• Apply parking brake before starting the engine.

• The vehicle is to be secured against moving forwards or

backwards.

• The person performing tests on a vehicle with the

engine running must sit in the driver’s seat to be able to

prevent the vehicle from moving.

• It is not permitted for persons to be in the danger zone

in front of or behind the vehicle while tests are being

performed.

• Shift the gearshift lever to neutral on vehicles with

manual transmission.

• On vehicles with automatic transmission, move selector

lever into position “P” or “N” (except for vehicles that

do not have selector lever position “P”).

• On vehicles that do not have selector lever position “P”,

the selector lever is to be secured against

unauthorized access.

• Wear closed and snug-fitting work clothes.

• Remove all jewelry such as necklaces, rings, etc.

• Wear suitable head wear to cover long hair.

• Before commencing any work on the running engine,

familiarize yourself with the location of potentially hot

parts.

• When carrying out work when starting the engine or

when the engine is running, do not touch any hot or

rotating parts.

• Use the exhaust extraction system.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

First aid measures in the event of burns

• Do not rub the skin areas affected; rinse with plenty of

cold water and cover skin with sterile dressings.

• Consult a physician immediately.

Risk of accident from vehicle starting off by itself when engine running. Risk of injury (bruises and burns) resulting from

working on the engine while it is being started or when it is running.

a Emissions Campaign 2020040003

5

Risk of injury. Moving parts

can pinch, crush or, in extreme

cases even sever extremities.

No parts of the body or limbs

should be within the operating

area of mechanical components

when moving components.

aWarning

Risk of injury

When working on components that can be moved either by

hand, by means of electric motors, or hydraulically/

pneumatically via a connecting mechanism, serious injuries

can occur due to body parts being cut, pinched or crushed.

Safety instructions/precautions

• Monitor hazard area.

• Secure the operating area of mechanical components

against interference when parts are in motion.

• Never touch the mechanism of a component while it is

being actuated by electric motors via the diagnosis or by

direct actuation (terminal 30).

• Choose a test cable of sufficient length.

Risk of injury. Moving parts can pinch, crush or, in extreme cases even sever extremities.

a Emissions Campaign 2020040003

6

Risk of death caused by

vehicle slipping or toppling off of

the lifting platform.

Align vehicle between vehicle lift

columns and position the four

support plates at the vehicle lift

support points specified by the

vehicle manufacturer.

aDanger

Risk of accident and injury

Ensure that the vehicle is ideally aligned and secured

against tilting according to the general safety specifications

and regulations.

Non-observance of the safety specifications can cause the

vehicle to slip off the lift system and thereby result in life

threatening or fatal injuries.

i

This list of hazards is not complete.

The safety specifications of the respective country are

always valid. The user is personally responsible for

complying with these.

Risk of death caused by vehicle slipping or toppling off of the lifting platform.

a Emissions Campaign 2020040003

7

Risk of burn injuries and

scalding when working at

AdBlue® lines and the

components attached to them.

Risk of injury to skin and eyes

when handling AdBlue®. Risk

of poisoning caused by

swallowing AdBlue®

Pour AdBlue® into suitable

containers only. Wait until the

pressure is released before

starting any work on the

exhaust aftertreatment system.

aWarning

Potential risks

Risk of burn injuries and scalding

The AdBlue® lines and all components attached to them

are under pressure during operation and remain so after

the engine is switched off and may be hot. There is a risk of

burn injuries. There is a risk of scalding caused by

escaping hot AdBlue® when the line system is opened.

Risk of injury

There is a risk of skin irritation and eye damage on contact

with AdBlue®.

Risk of poisoning

There is a risk of poisoning if AdBlue® is swallowed.

Rules of conduct

On vehicles with a compressed air system, individual

lines are flushed with compressed air after the engine is

switched off. The engine must therefore be switched off

for at least 5 minutes before work on the exhaust

aftertreatment system may begin.

• Open connections and plugs on the system components

slowly. Cover the connecting point with rags when

opening.

•

•

Only pour AdBlue® into marked containers specially

designated for the purpose. Do not pour AdBlue® into

drinking containers.

Wipe up any AdBlue® spills immediately as there is a

high risk of someone slipping.

• On vehicles with electrical delivery pump, the AdBlue®

is pumped from the line back into the AdBlue® tank

after the engine is switched off.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Safety precautions for handling removed parts and

working under the vehicle

• Wear suitable protective gloves

• Wear protective clothing

• Wear safety glasses

First aid measures

Contact with skin: Wash the affected skin areas with plenty

of clean water. Change wetted clothing as quickly as

possible.

Contact with eyes: In the event of contact with eyes,

immediately rinse eyes thoroughly with plenty of clear

water; contact an eye doctor if necessary.

Ingestion: rinse mouth with clean water and drink large

quantities of water. Immediately seek medical assistance.

Firefighting measures

AdBlue® is not combustible. NH3 (ammonia) can be

released in the event of fire, causing a risk of poisoning.

Firefighting measures must therefore be suited to the

surroundings.

Risk of burn injuries and scalding when working at AdBlue® lines and the components attached to them. Risk of injury

to skin and eyes when handling AdBlue®. Risk of poisoning caused by swallowing AdBlue®

a Emissions Campaign 2020040003

8

Risk of burn injuries,

suffocation and poisoning when

working on the exhaust system

and the components connected

to it. Risk of suffocation and risk

of poisoning caused by

inhalation of gaseous and solid

components of the exhaust.

Risk of poisoning caused by

skin contact with solid

components of the exhaust.

Wear protective clothing and

safety glasses. Use the

extraction system. Move people

out of the hazard area.

aWarning

Risk of burn injuries

The exhaust system and all components connected to it

are very hot during operation and remain so after the

engine is switched off. Do not touch hot parts.

Risk of suffocation and poisoning

Exhaust gases may also cause cancer.

At higher concentrations, irritation of mucous membranes

and headaches may occur. Carbon monoxide may cause

damage to unborn children.

Avoid inhalation of exhaust gases; wear respiratory

protection.

Use the exhaust extraction system.

Risk of injury

Risk of injury to the eyes, skin, and respiratory paths due to

contact with exhaust residues such as diesel particulates

and diesel soot. To prevent skin contact on hands, wear

nitrile gloves.

First aid measures

In the event of inhalation:

Move victim from the hazard area to fresh air without

endangering yourself and consult a physician immediately.

After contact with skin:

Immediately wash affected areas of the body with plenty of

soap and water. Employees who have experienced skin

contact must consult a physician immediately.

After contact with eyes:

Rinse eyes thoroughly with running water for at least ten

minutes with the eyelids wide open and contact an eye

doctor immediately.

Risk of burn injuries, suffocation and poisoning when working on the exhaust system and the components connected to it.

Risk of suffocation and risk of poisoning caused by inhalation of gaseous and solid components of the exhaust. Risk of

poisoning caused by skin contact with solid components of the exhaust.

a Emissions Campaign 2020040003

9

Risk of explosion from

explosive gas. Risk of

poisoning and caustic burns

from swallowing battery

electrolyte. Risk of injury

through burns to skin and eyes

from battery acid or when

handling damaged lead-acid

batteries

No fires, sparks, open flames or

smoking. Wear acid-resistant

gloves, clothing and glasses.

Only pour battery acid into

suitable and appropriately

marked containers.

aDanger

Potential risks

Risk of explosion

When charging lead batteries with battery electrolyte

containing sulfuric acid, a highly explosive oxyhydrogen

gas mixture is created that ignites by means of fire, sparks,

open flames and smoking.

Risk of injury

The battery electrolyte contains diluted sulfuric acid that

causes caustic burns to the skin, eyes and mucous

membranes in the event of contact. Bonded electrolyte is

just as caustic as liquid electrolyte. Battery electrolyte mist

causes caustic burns to the eyes. If inhaled, this can result

in caustic burns to the mucous membranes and respiratory

paths. In the event of a short circuit from the battery

positive to ground, battery terminals and conductive objects

causing short circuit, e.g. tool or jewelry (watch band or

ring), become hot in seconds and red hot/liquid metal

sprays are released.

Risk of burn injuries

In the event of a short circuit from the battery positive to

ground, battery terminals and conductive objects causing

short circuit, e.g. tool or jewelry (watch band or ring),

become hot in seconds and cause burns.

Risk of poisoning

If battery electrolyte is swallowed, this can result in

symptoms of poisoning such as headache, dizziness,

stomach ache, respiratory paralysis, unconsciousness,

vomiting, caustic burns and cramps. Absorption of lead in

the body through contact with leaded components (battery

terminals, lead plates in damaged batteries) damages the

blood, nerves and kidneys; lead compounds are also toxic

for reproduction.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Safety precautions/instructions

• Wear acid-resistant gloves and clothing and safety

glasses with side guards.

• Only charge lead batteries in well ventilated rooms with

appropriate voltage and appropriate current with

approved chargers, taking into account the instructions

of the battery and battery charger manufacturers.

• No fire, sparks, open flames and smoking.

• Switch on the battery charger only after connecting to

the terminals; switch off the battery charger before

disconnecting from the terminals.

• Do not place any conductive objects on the battery and

do not wear any conductive jewelry (risk of short circuit).

• Always disconnect the negative terminal first; always

connect the positive terminal first (risk of short circuit

caused by tool).

• Strict caution is required when handling damaged

batteries (removing from vehicle damaged in accident)

because of the sharp edges on the fractured housing

and escaped electrolyte.

• Keep batteries and battery electrolyte away from

unauthorized persons (especially children).

• Only fill liquid battery electrolyte into suitable and

appropriately marked containers.

• Only store, transport and install batteries with liquid

battery electrolyte horizontally, otherwise battery

electrolyte can escape from the degassing holes.

• Ensure that at least one degassing hole at the battery is

not sealed, as otherwise overpressure builds that leads

to bursting of the battery.

• Ensure proper connection of the degassing line to the

degassing hole.

• Ensure the degassing line does not have any kinks and

is not blocked at any point.

• Observe the instructions for use for the respective lead

batteries and the operator’s manual of the vehicle.

• The battery housing may become brittle over time,

therefore do not expose the battery to direct sunlight.

• Discharged batteries may freeze and are thereby

damaged, therefore always store batteries at a location

protected against frost.

Risk of explosion from explosive gas. Risk of poisoning and caustic burns from swallowing battery electrolyte. Risk of

injury through burns to skin and eyes from battery acid or when handling damaged lead-acid batteries

a Emissions Campaign 2020040003

10

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

First aid measures

Contact with eyes

• Rinse eyes immediately with plenty of water.

Contact with skin

• Remove wet clothing.

• Immediately neutralize battery electrolyte on the skin or

clothing with acid neutralizer or soapy water and rinse

off with plenty of water.

• Wash off lead on the skin immediately with water and

soap.

Inhalation of battery electrolyte mist

• Take the affected person out into the fresh air.

Swallowing battery electrolyte

• Have the person affected drink plenty of water with

activated charcoal supplement.

As a general rule, the person affected should consult a

medical service or physician after first aid has been

rendered.

Fire protection measures

Suitable extinguishing agents

• CO2 and dry extinguishing agent

Warning notes for lead batteries with battery electrolyte containing sulfuric acid

1 No fire, sparks, open flames or

smoking

4 Risk of caustic burns 6 Keep away from children

2 Risk of explosion 5 Wear eye protection 7 First aid

3 Observe operating instructions

Risk of explosion from explosive gas. Risk of poisoning and caustic burns from swallowing battery electrolyte. Risk of injury

through burns to skin and eyes from battery acid or when handling damaged lead-acid batteries

a Emissions Campaign 2020040003

11

Risk of injury caused by

contact with battery gel when

handling damaged leadgelbatteries

No fires, sparks, open flames or

smoking. Wear acid-resistant

gloves, clothing and glasses.

aWarning

Potential risks

Risk of poisoning

Swallowing battery gel can cause symptoms of poisoning

such as headaches, dizziness, stomach aches, respiratory

paralysis, unconsciousness, vomiting, caustic burns and

cramps.

The absorption of lead in the body can cause damage to

blood, nerves and kidneys; in addition, lead compounds are

considered to represent a reproductive hazard.

Risk of injury

The bonded electrolyte set free is just as caustic as a

liquid electrolyte that can cause heavy caustic burns to skin

and eyes. Strict caution is required when handling

damaged lead-gel batteries (e.g. removing from vehicle

damaged in accident) because of the sharp edges on the

fractured housing and direct contact with the lead plates.

Safety precautions and rules of conduct

• No fires, sparks, open flames or smoking.

• Do not place any tool or other conductive object on the

lead-gel battery (risk of short circuit!).

• Disconnect and remove lead-gel batteries for charging.

• Always disconnect the negative terminal first and

always connect the positive terminal first .

• Only switch on the battery charger after connecting to

the terminals and switch off before disconnecting.

• Keep lead-gel batteries away from unauthorized

persons (especially children).

• Pay attention to instructions for use of the particular

lead-gel battery and the operator’s manual for the

vehicle.

• Wear acid-resistant clothing and safety glasses with

side guards.

• Only pour acid gel into suitable and appropriately

marked containers.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

First aid measures

Contact with eyes

• Rinse out eyes immediately with plenty of water.

Contact with skin

• Remove moistened clothing.

• Immediately neutralize drops of acid or gel on skin or

clothing with acid neutralizer or soapy water and rinse

off with plenty of water.

Swallowing battery gel

• Have the person affected drink plenty of water

supplemented with activated charcoal.

After performing first aid, always consult medical

service or a physician.

Fire protection measures

Suitable extinguishing agents

• CO2 and dry extinguishing agent

Risk of injury caused by contact with battery gel when handling damaged lead-gelbatteries

a Emissions Campaign 2020040003

12

Notes on avoiding damage

through contamination and

foreign objects

Topical note

Information on affected component parts

With each maintenance and repair work to the engine as

well as to the ancillary assemblies and detachable parts

comes the danger of property damage caused by

contamination and foreign bodies.

Particularly at risk are:

• Exhaust gas turbocharger

• Hot film mass air flow sensor

• Compressor

• Emission control system

• All components involved in gas exchange

Notes on removal/installation

Openings through which soiling or foreign objects are

introduced into the engine, its ancillaries or detachable

parts, must be sealed immediately.

For this purpose, suitable, clean covers and plugs or clean,

lint-free rags are to be used.

p

Do not forget to remove all covers, plugs or rags when

assembling or when finalizing the work.

This avoids any damage and complaints about engine

running characteristics.

g

Before assembling or finalization work all components

are to be checked for soiling, left-over foreign objects and

any fluids, and if any are found they are to be removed.

Information on cleaning

For cleaning, use only clean tools and clean, lint-free rags.

Residues of cleaning agents and removed contaminants

must be cleared from the engine, ancillary assemblies and

detachable parts.

p

Do not use compressed air for removing any soiling.

Otherwise, components (e.g. the hot-wire element of the

hot film mass air flow sensor) could be damaged or

contamination could enter the engine, ancillary assemblies

and detachable parts without being noticed.

Notes on avoiding damage through contamination and foreign objects

a Emissions Campaign 2020040003

13

Notes on use, material

properties and handling of

AdBlue®

Topical note

Tasks of AdBlue®

AdBlue® serves to convert nitrogen oxides into water vapor

and nitrogen.

Chemical characterization and composition of

AdBlue®

The urea content is 32.5%. AdBlue® consists of urea

dissolved in demineralized water. AdBlue® is not an

additive.

Chemical formula: H2N-CO-NH2

Molecular weight (urea): 60.06 g/mol

CAS (Chemical Abstracts Service) no.: 57-13-6

Marking

AdBlue® dispensers are marked with the standard

designation ISO 22241 or with the trade designations

AdBlue® or Diesel Exhaust Fluid (DEF).

Transport

In vehicles with BlueTEC technology, AdBlue® is carried in

a tank.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Physical and chemical properties of AdBlue®

State: Liquid

Color: Colorless, clear, light-yellow

Odor: Slight ammonia odor

pH value: 10 (aqueous solution, 10 %)

Crystallization temperature: –11 °C / 12 °F

Boiling point: 103 °C / 217 °F

Auto-ignition temperature: Not spontaneously inflammable

Density: approx. 1.09 g/cm3 at 20 °C / 68 °F

Viscosity (dynamic): approx. 1.4 mPa*s at 25 °C / 77 °F

Handling contaminated operating fluids

It is essential that AdBlue® be kept separate from other

operating fluids, fuels and lubricants such as coolant,

engine oil, transmission oil, fuel, hydraulic fluid and brake

fluid and not used in the same containers and collecting

bowls. The smallest amounts of AdBlue® can damage

thermostats or temperature sensors.

Operating fluids which contain traces of AdBlue® must not

be used again.

Handling contaminated AdBlue®

AdBlue® must be checked as per the repair instructions

before every fill. Individual components of the exhaust

aftertreatment system already react very sensitively with

even the smallest traces of contaminants in AdBlue®.

When handling AdBlue® it is important, therefore, to

always use clean containers and collecting bowls which are

only reserved for this purpose. Contaminated AdBlue®

must not be used again.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Handling contaminated materials

It is essential that AdBlue® does not come into contact with

materials used in the interior of the vehicle. AdBlue®

exposed to air passes within just a few hours from a liquid

state into the crystalline state and can therefore damage

and destroy contaminated surfaces.

Textiles, e.g. the reversible mat in the luggage

compartment, which have been fouled with AdBlue®

should be alternately cleaned and then rinsed with water

several times.

It must be ensured that there are no further traces of

AdBlue® in the textiles.

Handling contaminated tools

All tools coming into contact with AdBlue® must be

thoroughly cleaned with water immediately after use!

Only fully dried measuring instruments and filling tools

should be used so as not to dilute the AdBlue®

concentration.

Protecting components when working with AdBlue®

AdBlue® leads to corrosion on electronic components and

strong fouling on all other materials. It is therefore

necessary to cover up all components in the vicinity over

the whole surface with plastic foil when working in

circumstances where AdBlue® could leak out.

Storage and packaging

Storage at temperatures between 0°C/32°F and 25°C/77°F

should be ensured in order to avoid crystallization occurring

Notes on use, material properties and handling of AdBlue®

a Emissions Campaign 2020040003

14

in AdBlue®. To avoid deterioration in quality due to

contamination, AdBlue® must only be handled in storage

and filling systems intended exclusively for AdBlue®.

Suitable container materials are alloyed steel, various

plastics and plastic coatings in metal containers.

Not to be used are unalloyed steel, aluminum, copper,

copper-containing alloys and zinc-dipped steel.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Service life and durability

AdBlue® breaks downs during storage into ammonium

hydroxide and carbon dioxide and then no longer fulfills the

requirements of standard ISO 22241.

If the recommended storage temperature of a maximum of

25°C/77°F is maintained, the AdBlue® will fulfill the

requirements of this standard for at least 18 months after

manufacture. If this recommended storage temperature is

exceeded then this period is reduced. Duration of storage

and the temperatures to be used are given as guideline

values at the end of the document. At temperatures below

-11°C/12 °F, the AdBlue® freezes and becomes solid.

On warming up again the frozen AdBlue® becomes liquid

again and can be reused without any loss of quality.

The maximum permissible service life of AdBlue® can be

taken from the MB Specifications for Operating Fluids.

Disposal and degradability

Disposal of AdBlue®:

When disposing of AdBlue® the legal requirements of the

country in which the AdBlue® is used must be observed.

Contaminated packaging/materials:

Packaging which contains residues of AdBlue® is to be

handled like the substance itself. Packaging should

emptied as well as possible; it can then be reused after

appropriate cleaning with water.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Constant ambient conditions

Storage temperature in °C/°F – Durability in months

≤10 / 50 – 36

≤25 / 77 – 18

≤30 / 86 – 12

≤35 / 95 – 6

>35 / 95 – —

Notes on use, material properties and handling of AdBlue®

a Emissions Campaign 2020040003

15

Information on preventing

damage to electronic

components due to electrostatic

discharge

Topical note

Electrostatic charge

Every contact and every physical separation of materials or

every movement of solids, liquids or charged particlecontaining

gases can generate electrostatic charge.

Plastics generally produce the highest electrostatic charge.

We come across electrostatic charge or discharge in lots of

everyday situations, e.g. with:

• Combs

• Walking on carpets or plastic floors

• Putting on and taking off textiles with synthetic fiber

content

• Disembarking from the vehicle

• Contact between various electrostatically chargeable

packaging materials in shelves or in the transport

container

The resulting electrostatic discharge (Electrostatic

Discharge (ESD)) can be so strong that a small electric

shock is detected. Even the smallest discharges which

people cannot detect can cause lasting damage to

electronic components and control units.

Effects and consequences of ESD

Electronic components and control units are very sensitive

to ESD. The damage is often not immediately obvious, but

becomes apparent some time later. In order to avoid

failures and damage due to ESD in vehicle electronics,

various procedures and safety precautions must be taken

into account and followed.

Risk of damage arises during the transportation, handling,

testing, removal and installation of electronic components

during production and repair work.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

The following electronic components listed as an example

can be damaged by ESD:

• Airbag components

• Control units, in particular their bus connections

Controller Area Network (data bus/CAN bus) (CAN),

Local Interconnect Network (LIN) etc.

• Sensors

• Mechatronic component parts (actuators etc.)

• Antenna amplifier

• Receivers and displays (Radio, TV, GPS, telephone

etc.)

Modes of behavior and safety precautions

• Electrostatic discharge of the technician (e.g. by briefly

touching the vehicle body).

• Suitable clothing, e.g. made of cotton.

• Wear ESD safety shoes with conductive soles.

• Keep workplace clean and clear away unnecessary

objects such as conventional plastics.

• Special antistatic seat cushion protectors should be

used when performing repair work inside a vehicle.

• Leave replacement parts in the original packing for as

long as possible, do not tear open seals but cut them

open carefully.

• The ESD workplace must conform to the ESD

guidelines.

• The operation-specific documentation in the WIS must

be observed and the specified special tools and/or

workshop equipment must be used in each case.

• Before unpacking, discharge ESD protective packaging

at the ESD workplace.

• Avoid any contact with electrostatic chargeable

materials such as, e.g. polyethylene, PVC, styrofoam.

• Use only original packaging or specially labeled and

defined packaging and transport materials.

• Electronic components which have been removed must

be put down on an ESD workplace.

• Electrical connectors on electronic component parts and

in the wiring harness should be touched by their

housing only. Do not touch pins or contacts!

• Electronic components must be installed before they are

connected so that potential equalization with the body

can take place.

• Shelves and worktables must stand directly on the floor,

there must not be any insulating materials between the

base of the shelves/feet and the floor. If the above

mentioned insulators cannot be removed, the shelves

and work tables must be grounded (e.g. low-resistance

electrical connection/line from metal shelf to a coolant

pipe).

• Do not put down conductive containers/crates when

insulated,

(e.g. on a wooden pallet), as otherwise potential

equalization will not take place.

Information on preventing damage to electronic components due to electrostatic discharge

a Emissions Campaign 2020040003

16

• Do not place control units and electronic components

removed from the vehicle on electrostatically

chargeable materials, such as PE, PVC, styrofoam. The

electrostatic charge is transferred to the control unit or

electronic component. An ESD service kit or a

connected ESD table mat must be used.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Training

It is strongly recommended that every company has an

ESD officer trained in accordance with DIN EN 61340-5-1.

The ESD officer can carry out staff training courses.

The aim of the training measures is to communicate the

main problems and effects of ESD to staff:

• Discharge generation

• Reasoning for safety precautions

• Effects and consequences of ESD

• ESD rules of conduct and safety precautions

Return of electronic components in warranty and

goodwill cases

When returning electronic components it is absolutely

essential to observe the procedure and safety precautions

listed. The original fault may be falsified or hidden by

electrostatic charge/discharge.

This can lead to distorted fault symptoms in the case of the

fault analysis of the component concerned.

Information on preventing damage to electronic components due to electrostatic discharge

a Emissions Campaign 2020040003

17

Notes on carrying out repair

work in the vehicle interior

Topical note

In order to prevent soiling or damage, the following

information must be observed:

• Before starting repairs in the vehicle interior, the

corresponding protective covers must be provided in the

repair area for the floor coverings, seats, steering

wheel, etc. to prevent them from becoming dirty.

• Persons performing work in the vehicle interior should

ensure they have clean work clothes, clean shows and

clean hands.

• When removing bulky or difficult to handle parts (e.g.

bench seat, roof lining, instrument panel etc.), always

work with aid of at least a second person.

• Do not use dirty or unapproved tools. This prevents any,

e.g. scratching or crazing of interior parts etc.

• Always place removed interior parts on a clean and soft

surface.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Further information:

• Repair or replace damaged interior parts (particularly

mounts such as retaining clips, Velcro fasteners etc.).

• When installing interior parts at the intended locations,

install insulation material and/or protective foils, or,

replace insulation material/protective foils as required in

order to dampen vibrations and noise.

• Many equipment parts in the area of the vehicle interior

have been installed or made specifically to the

customer’s request, and cannot be replaced easily if

damaged or soiled; for this reason, utmost care must be

ensured when carrying out operations in the vehicle

interior.

• Remove any dirt present with cleaners approved by

Daimler and suitable for corresponding surfaces. When

doing so, where possible, the compatibility of the

cleaning agent should be tested at a concealed area of

the part to be cleaned.

Notes on carrying out repair work in the vehicle interior

a Emissions Campaign 2020040003

18

Lift mounting points on the vehicle

in the area of the front axle

01 spring clamp plate

02 longitudinal member

08 bracket

011 arm of hydraulic lift

012 support plate

013 long support plate

017 support drift

Lift mounting points on the vehicle in the area of the rear axle

07 014

011 016

v-block

prop

03

04

06

front rear spring bracket

longitudinal member

front rear spring bracket 013

crossmember

arm of hydraulic lift

long support plate

Lift point locations

i

When performing procedure on a vehicle lift

i

Vehicle must be in a ready to lift position

before procedure is started.

i

Read the operating instructions for

the vehicle lift.

a Emissions Campaign 2020040003

19

Picture reference Pick-up point

Information

03 Support at rear to front rear spring

bracket.

04 Rear support at longitudinal member. ‑ If possible, always support at rear

Install at longitudinal member (4).

06 Install on front rear spring bracket.

012 Support plate. ‑ For front support to spring clamp plate

(1). Unscrew support plate (012) at right

and left an equal distance.

‑ In vehicles with vehicle lift support

point at integral carrier (5).

(5).

013 Long support plate. ‑ For front support at longitudinal

member (2) and support at front rear

spring bracket (6). Can be used

alternatively to front support to spring

clamp plate (1). Pull out long support

plates (013) at right and left an equal

distance.

‑ In vehicles without a vehicle lift

support point at the integral carrier (5)

(5)

in the vicinity of the inner mounts of the

semi-trailing arms.

014 V-block ‑ For rear support at front rear spring

bracket (3) and rear support at

longitudinal member (4). Pull v-block

(014) at right and left rear out an equal

distance.

016 Ram ‑ Vehicles with heavy bodies and panel

‑ Vehicles with heavy bodies and panel

vans/crewbuses with a long wheelbase

at the crossmember (7) should be

supported with a prop (016).

017 Support drift ‑ With soundproofing Ensure that

support drift (017) does not make

contact with bracket (8) of rear

soundproofing. If necessary, loosen

bracket (8), push towards the front as

far as possible and retighten it.

Otherwise the brackets (8) of the rear

soundproofing and the longitudinal

members may be damaged.

‑ For front support to longitudinal

member (2). Unscrew support drift

(017) at right and left an equal distance.

Secure vehicle on lift.

p

Heavily loaded vehicles, vehicles with a heavy body and

vehicles with unfavorable load distribution must be

secured.

Otherwise these may fall.

a Emissions Campaign 2020040003

20

Instructions for driving onto ramps

Read the operating instructions provided by the manufacturer

of the ramps. Since these are ramps that have not been built

or tested by Mercedes Benz, no information can be given on

Benz, no information can be given on

safety. Mercedes Benz excludes all liability when using these

Benz excludes all liability when using these

ramps.

1

2

Place the vehicle on a clean, firm and

level surface.

i

Make sure that there is enough space to

the front.

Place ramps in the middle (arrows A) of

the front wheels.

i

The ramps must be aligned parallel to

each other.

3

4

Drive the vehicle onto the ramps until it is

positioned in the end position specified by

the manufacturer of the ramps.

p

Drive the vehicle slowly and at a constant

speed onto the ramps.

Otherwise the vehicle may be damaged.

i

If necessary, include a helper to instruct

you.

Secure the vehicle against rolling away.

i

For example, by applying the parking

brake and by placing a wheel chock

(arrow B) on the rear wheels.

i

Vehicle must be driven onto ramps

before procedure is started, and

may remain on ramps for the

entire procedure.

i

Race Ramps are available for

order from MBUSA Standard

Service Equipment Program

(SSEP): www.mbusassep.com

Part number:

784-RR-HTVR-RC-KIT

i

i

When performing procedure on

ramps.

a Emissions Campaign 2020040003

21

Initial Quick Test

1

2

3

Switch off the ignition.

Disconnect Geotab, Omni Track, Navigation

or any aftermarket devices that are connected

to the X11/4 diagnostic socket.

Open the hood.

a

4 Connect the battery charger to the

vehicle’s jump posts as indicated.

(arrows)

p

A sufficient power supply to the

vehicle on-board system must be

ensured throughout the entire work

procedure.

Otherwise any undervoltage that

occurs may damage the control

units.

i

Do not connect the battery charger to

the auxiliary battery in the engine

compartment.

i

Follow the operating instructions for

the battery charger.

i

Use a Mercedes-Benz recommended

recommended

battery charger to ensure an

adequate voltage supply (min. 12.5 V)

is provided for the on-board electrical

system battery.

Emissions Campaign 2020040003

22

5

6

7

Ensure XENTRY is fully updated with the

latest release and all available add-ons.

Connect the diagnostic system. Make sure

that the OBD2 connection cable is

connected directly to the factory X11 / 4

diagnostic socket and not via an adapter

cable.

Switch on the ignition.

i

The diagnostic system remains connected to

the vehicle throughout the work procedure!

Do not disconnect the diagnostic system’s

online connection.

Start the diagnostic system.

9

10

Run XENTRY and perform Quick Test.

Upload Initial Quick Test print-out to

paperless pXD.

i

Pre-existing faults causing a Check Engine

Light must be evaluated. Reference Pre-

Inspection Notes on page 2.

i

The procedure via the diagnostic system

is shown on the following pages.

Perform Emissions Modification Pre-

Inspection.

8

a Emissions Campaign 2020040003

23

First

Second

Third

a Emissions Campaign 2020040003

24

wait

a Emissions Campaign 2020040003

25

a Emissions Campaign 2020040003

26

wait

a Emissions Campaign 2020040003

27

First

Fourth

Name file:

QT 1

Third

Second

a

i

Pre-existing faults causing a Check Engine Light must be

evaluated. Reference Pre-Inspection Guide on page 2.

Emissions Campaign 2020040003

28

First

Second

a

Pre-Inspection Special Procedure

Emissions Campaign 2020040003

29

a

i

If ????on-Compliant alterations are found???? reference the

Pre-Inspection Guide on page 2 for next steps.

Emissions Campaign 2020040003

30

11 End the XENTRY session.

a Emissions Campaign 2020040003

31

a

12

13

14

Switch off the ignition.

Disconnect the diagnostic system.

Disconnect battery charger.

Emissions Campaign 2020040003

32

16 Spray penetrating oil

on the threads of the

NOx sensor upstream

(3) and downstream

(5) of SCR catalytic

converter, as shown.

p

Exhaust system

should be cold in

order to carry out

the next steps.

This avoids injuries.

i

Observe the wait

period and details

provided by the

manufacturer of the

penetrating oil!

Replacement of AEM Parts

a

15 Lift:

Raise the vehicle.

i

A description of the lift points is

available on pages 19-20.

Ramps:

Vehicle may remain on ramps.

Emissions Campaign 2020040003

33

a

17

18

19

20

21

22

23

i

This is done by bending up the individual locking

fins with a screwdriver and unscrew the clamping

nut (48) in a counter-clockwise direction with a

screwdriver.

i

To do this, unlock the gray retaining tab by moving

in the direction of the arrow.

i

To do this, remove and dispose nuts (46)

i

Observe state-specific regulations for disposal.

Loosen the heat shield (47).

Bend the heat shield (47) down until the NOx

sensor control unit upstream of the SCR catalytic

converter (23) is accessible.

Disconnect the electrical plug connection (24)

NOx sensor control unit upstream of the SCR

catalytic converter (23).

Remove the NOx sensor control unit upstream of

the SCR catalytic converter (23) from the frame.

Remove and dispose the cable ties and retaining

clips (arrows) from harness (22) of the NOx

sensor control unit upstream of the SCR catalytic

converter (23).

Remove NOx sensor upstream (3) of the SCR

catalytic converter.

i

The control unit and the NOx sensor upstream

(3) of the SCR catalytic converter are a single

unit.

i

Return the NOx sensor upstream of SCR catalytic

converter (3) to the originating parts department.

Clean the threads and the contact surfaces on the

exhaust pipe.

Removal of Upstream NOx Sensor

Emissions Campaign 2020040003

34

a

27

25

26

24 Remove and dispose mounting tab

(34) from harness (32).

i

Observe state-specific regulations

for disposal.

Remove and dispose of the

clamping nuts (26).

i

This is done by bending up the

individual locking fins with a

screwdriver and unscrew the

clamping nuts (26) in a counterclockwise

direction with a

screwdriver.

Remove the heat shield (25).

28

Disconnect the electrical plug connection (30) at the NOx

sensor control unit downstream of the SCR catalytic

converter (27).

Remove the NOx sensor control unit downstream of the

SCR catalytic converter (27).

Remove the NOx sensor downstream of the SCR catalytic

converter (5).

i

The control unit and the NOx sensor downstream of the

SCR catalytic converter (5) are a single unit.

i

Return the NOx sensor downstream of the SCR catalytic

converter (5) to the originating parts department.

i

To do this unlock the gray locking device (29)

by moving in the direction of the arrow.

i

To do this, remove and dispose the nuts (28)

and cable tie (31).

i

Observe state-specific regulations for disposal.

29

Removal of Downstream NOx Sensor

Emissions Campaign 2020040003

35

30

31

32

33

Installation of Upstream NOx Sensor

34 Bend the heat shield (47) back into

old position and install a new clamping nut

(48).

A 000 994 32 11

i

To do this, place the clamping nut (48)

centrally on the pin, as shown, and slide up

to the stop using a socket wrench.

Install new NOx sensor

upstream of SCR catalytic

converter (3).

i

A 000 905 85 11 80

(included in package

A 642 905 19 00 85)

NOx sensor upstream of SCR

catalytic converter: Torque to

60 Nm / 44.3 ft·lb

Install the NOx sensor control

unit upstream of the SCR

catalytic converter (23) on the

frame.

i

Use new nut fasteners (46):

N 000000 003477

NOx sensor control unit:

Torque to 9 Nm / 6.6 ft·lb

Connect the electrical plug

connection (24).

i

Push the gray retaining tab

(24.1) in the direction of the

arrow to lock.

Secure the harness (22) with

a cable tie.

i

A 007 997 56 90 (1x)

a Emissions Campaign 2020040003

36

35

37

36

Install new NOx sensor control unit

downstream of the SCR catalytic

converter (27).

i

A 000 905 84 11 80 (included in

package A 642 905 19 00 85)

Use new nut fasteners:

N 000000 003477

NOx sensor control unit: Torque to

9 Nm / 6.6 ft·lb

Install the new NOx sensor

downstream of the SCR catalytic

converter (5) on the new SCR catalytic

converter.

i

NOx sensor downstream of catalytic

converter: Torque to 60 Nm / 44.3 ft·lb

38

Connect and lock the electrical plug

connection (30).

i

Push the gray locking piece (29) in the

direction of the arrow to lock.

Secure harness (32) with cable tie (31).

i

A 007 997 56 90 (1x)

a

p

Do not route the harness (32) under tension.

Otherwise damage could occur.

Installation of Downstream NOx Sensor

Emissions Campaign 2020040003

37

39 Install the heat shield (25).

i

To do this, place the new

clamping nuts (26) centrally

on the pin, as shown, and

slide up to the stop using a

socket wrench.

i

A 000 994 32 11

40

41

Install the new mounting tab (34) on the heat shield (25).

i

A 220 546 18 43

Clip the harness (32) into the mounting tab (34).

p

Do not kink the harness (32) and make sure it is not routed

so as to be abraded.

This prevents damage.

p

The harness (32) must not touch heat shield (25).

This prevents damage.

i

The layout schematic of the harness (32) has changed on

account of the changed position of the NOx sensor

downstream of the SCR catalytic converter (4).

Lift:

Lower the vehicle.

Ramps:

Vehicle may remain on ramps

42

a Emissions Campaign 2020040003

38

Execution of the AEM Special Procedure

43

a

Connect the battery charger to the

vehicle’s jump posts as indicated.

(arrows)

p

A sufficient power supply to the

vehicle on-board system must be

ensured throughout the entire work

procedure.

Otherwise any undervoltage that

occurs may damage the control

units.

i

Do not connect the battery charger to

the auxiliary battery in the engine

compartment.

i

Follow the operating instructions for

the battery charger.

i

Use a Mercedes-Benz recommended

recommended

battery charger to ensure an

adequate voltage supply (min. 12.5 V)

is provided for the on-board electrical

system battery.

Emissions Campaign 2020040003

39

a

Connect the diagnostic system.

i

The diagnostic system remains connected to the vehicle

throughout the work procedure!

Do not disconnect the diagnostic system’s online connection.

Switch on the ignition.

Start the diagnostic system.

44

46

45

47

Emissions Campaign 2020040003

40

Run XENTRY and start special procedure of

customer service measure.

i

To do this, select the following menu items: N3/35 –

Motor electronics ‘CDI60’ for combustion engine

‘OM642’ (CDI) (Code: MH3|MH5|MH7) → Special

procedures → Service measure “Exhaust gas aftertreatment”

i

The process starts automatically after starting the

special procedure. The operation steps must be

performed exactly as per the diagnostic system.

If a fault arises during the special procedure,

repeat the procedure. If the fault persists, create a

PTSS case or XSF-ticket including the following:

A result report is displayed at the end of the

special procedure. Upload this report to

paperless pXD. The report must indicate “OK” for

all items. Otherwise, the procedure must be

repeated. The vehicle can only be returned to the

customer after successfully completing the

special procedure.

i

Parts of the procedure via the diagnostic system

are shown on the following pages.

•Initial Quick test

•Current Quick test

•Control unit log

•AEM Result Report

•Support Packag

i

i

First

Second

Third

a Emissions Campaign 2020040003

41

wait

a Emissions Campaign 2020040003

42

a Emissions Campaign 2020040003

43

wait

a Emissions Campaign 2020040003

44

First

Second

First

Third

Second

a Emissions Campaign 2020040003

45

a Emissions Campaign 2020040003

46

Make sure it’s unchecked

a Emissions Campaign 2020040003

47

48 Complete the information on the

APPROVED EMISSION

MODIFICATION LABEL and attach it to

the hood near the hood lock.

p

The attachment areas must be entirely

free from dust and grease.

Otherwise, adequate adhesion cannot

be ensured.

i

Fill in Emission Modification Program

No., your dealer code, the date of the

repair and mark the components that

have been installed or modified. Use a

black ultra fine point permanent marker.

i

A 000 584 93 13

Failure to comply may result in dealer

debit and/or possible fines.

a Emissions Campaign 2020040003

48

Verify completed

successfully

a Emissions Campaign 2020040003

49

First

Second

Fourth

Third

Fifth

a

Name file:

AEM Results

Emissions Campaign 2020040003

50

a

49 Perform a final quick test and upload to paperless pXD.

i

Faults stored in the memory????must be deleted from the

fault memory after completing the work.

i

If faults are current and stored in the updated control

modules they need to be addressed. If technical

hardships occur create a PTSS ca????????????

The procedure via the diagnostic system is shown on

the following pages.

Final Quick Test

Emissions Campaign 2020040003

51

a Emissions Campaign 2020040003

52

wait

a Emissions Campaign 2020040003

53

First

Fourth

Name file: QT 2

Third

Second

a Emissions Campaign 2020040003

54

50 End the XENTRY session

a Emissions Campaign 2020040003

55

a

Switch off the ignition.

????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????

51

52

54

55

56

Close the hood.

Connect any aftermarket devices that

were connected to the X11/4 diagnostic

socket before.

Ramps:

Remove wheel chocks, release parking

brake, and drive the vehicle off the

ramps.

p

Drive the vehicle slowly and at a

constant speed off the ramps.

Otherwise the vehicle may be

damaged.

53 ????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????????

Emissions Campaign 2020040003

56

Replacement parts 2020040003

Part No. Designation Quantity

A 642 905 19 00 85 NOx Sensor package 1

A 220 546 18 43 Mounting Tab 1

A 000 994 32 11 Lock Pin 4

A 007 997 56 90 Cable Tie (with holding clip) 2

N 000000 003477 Nut Fastener 4

A 000 584 93 13 APPROVED EMISSION MODIFICATION LABEL 1

a Emissions Campaign 2020040003

57

SEOCONTENT-END

2020040003 Modification to the emissions control system

Model 906

Model Year 2015

Loading...

Loading...

- [Easy to Use--Work out of box] + [FOXWELL 2025 New Version] FOXWELL NT604 Elite scan tool is the 2025 new version from FOXWELL, which is designed for those car owners who want to figure out the cause issue before fixing the car problem via scanning the most common systems like abs

srs engine and transmission.The NT604 Elite diagnostic tool comes with latest software, which can be used out of box. No need to waste time to download the software first.

srs engine and transmission.The NT604 Elite diagnostic tool comes with latest software, which can be used out of box. No need to waste time to download the software first. - [Affordable] + [Reliable Car Health Monitor] Will you be confused what happen when the warning light of abs

/srs/transmission/check engine flashes? Instead of taking your cars to dealership, this foxwell scanner will help you do a thorough scanning and detection for your cars and pinpoint the root cause. It will t-urn off the warning light car after the problem is fixed.👉TIPS: Airbag crash/collision data can NOT be cleared even you replace the new airbag.

/srs/transmission/check engine flashes? Instead of taking your cars to dealership, this foxwell scanner will help you do a thorough scanning and detection for your cars and pinpoint the root cause. It will t-urn off the warning light car after the problem is fixed.👉TIPS: Airbag crash/collision data can NOT be cleared even you replace the new airbag. - [5 in 1 Diagnostic Scanner] Compared with those auto scanners (50-100), NT604 Elite code scanner not only includes their OBDII diagnosis but also it can be an abs

/srs scanner, transmission and check engine code reader. When it’s an odb2 scanner, you can use it to check if your car is ready for annual test through I/M readiness menu. In addition, live data stream, built-in DTC library, data play back and print, all these features are a big plus for it. Note: doesn't support maintenance function.

/srs scanner, transmission and check engine code reader. When it’s an odb2 scanner, you can use it to check if your car is ready for annual test through I/M readiness menu. In addition, live data stream, built-in DTC library, data play back and print, all these features are a big plus for it. Note: doesn't support maintenance function. - [Fantastic AUTOVIN] + [No extra software fee] Through the AUTOVIN menu, this NT604 Elite car scanner allows you to get your V-IN and vehicle info rapidly, no need to take time to find your V-IN and input one by one. What's more, the NT604 Elite abs

srs scanner supports 60+ car makes from worldwide (America/Asia/Europe). You don’t need to pay extra software fee.

srs scanner supports 60+ car makes from worldwide (America/Asia/Europe). You don’t need to pay extra software fee. - [Solid protective case KO plastic carrying bag] + [Lifetime update] Almost all same price-level obd scanner diagnostic tool only offers plastic bag to hold on the scanner.However, NT604 Elite automotive scanner is equipped with solid protective case, preventing your obd2 scanner from damage. Then you don’t need to pay extra money to buy a solid toolbox.

- [Pro OBD2 Scanner] - BlueDriver is the easiest way to scan and understand your vehicle like a professional mechanic. Read and clear your car’s trouble codes and check engine light.

- [Read & Clear All The Codes] - BlueDriver's enhanced vehicle diagnostics gives you access to information normally available only to mechanics on their OBD2 scan tools. Now you can read and clear ABS

, Airbag, SRS, TPMS codes, and many more.

, Airbag, SRS, TPMS codes, and many more. - [Get The Right Fix & View Live Data] - Much more than a car code reader, BlueDriver is a diagnostic tool. You’ll get unlimited repair reports with possible causes and fixes, plus real-time health monitoring while you drive with the live data feature.

- [Wireless & Bluetooth Enabled] - Say goodbye to wires. BlueDriver connects with Bluetooth via your phone/tablet to a sensor that plugs into your car's OBDII port. Get all of the capabilities of an expensive code reader & scan tool without any annoying wires.

- [User-Friendly App and Repair Videos] - BlueDriver gives you more ways to scan and fix your vehicle. Our iOS & Android app connects you to a large database of repair videos with step-by-step directions of repairs.

- [Brand-New ArtiDiag500] We've got everything you're looking for! Forget basic OBD2 scanners; TOPDON's ArtiDiag500 car scanner offers more. The all-new ArtiDiag500 not only includes full OBD2 functions and 4-system diagnostics but also provides DIYers with 6 maintenance services. The brand-new, cost effective AD500 is back in full swing!

- [4-System Diagnostics] DIY enthusiasts, take notice! Will these 4-system diagnostics be the treasure you've been seeking? The ArtiDiag500 code reader offers in-depth testing for the engine, transmission, ABS

, and SRS systems, reading fault codes and data streams. It also visualizes real-time data in chart form, simplifying complex data for storage and future playback, aiding DIY users in problem detection.

, and SRS systems, reading fault codes and data streams. It also visualizes real-time data in chart form, simplifying complex data for storage and future playback, aiding DIY users in problem detection. - [6 Reset Functions] Hey, hang tight for a moment. With these 6 reset functions, the ArtiDiag500 has got you covered. It offers throttle adaptation along with reset capabilities for Oil, SAS, TPMS, BMS, and EPB. Seamlessly aligning the throttle, battery, tires, and brake pads with your vehicle, it also adjusts the steering angle and turns off the oil light. Looking to restore your car to its original condition? Look no further than the ArtiDiag500.

- [Multiple Functions] The Smart AutoVIN of this TOPDON OBD2 scanner keeps track of your manual selections for vehicle make, model, and year and directs you to the suitable diagnostics. Max 4 Live Data streams integrated for much easier data processing. Diagnostic feedback online with this diagnostic tool to help you get tough repair operations well-completed. Real-time car battery voltage monitoring identifies probable vehicle defects.

- [Global Support] Rest assured about compatibility with your vehicle and language – ArtiDiag500 currently supports 67+ car brands, 10,000+ models, covering most vehicles worldwide, and is available in 12 languages. Whether it's for your car or preferred language, there's an ideal choice for you. Plus, it's fully compatible with Android 11 for smoother use.

- [ABS Diagnosis] - Quickly identify and resolve ABS

-related issues, including sensor faults (such as wheel speed sensors), wiring problems (faulty circuits or connectors within the ABS

-related issues, including sensor faults (such as wheel speed sensors), wiring problems (faulty circuits or connectors within the ABS system), or ABS

system), or ABS pump failures (malfunctions in the ECU controlling the ABS

pump failures (malfunctions in the ECU controlling the ABS ). Ensure proper system operation, restore optimal braking performance, and clear any warning lights.

). Ensure proper system operation, restore optimal braking performance, and clear any warning lights. - [SRS Diagnosis] - Quickly detect the airbag ECU itself, airbag sensor failure, airbag system plug disconnection or poor contact, seat belt sensor failure, or system error, etc, to ensure that the SRS (Supplemental Restraint system) is working properly. After repair, reset the system to clear the warning light and restore full safety performance. NOTE: It cannot reset Airbag crash or transmission codes.

- [Full OBD2 Function] - Read and clear trouble codes for all OBD2 systems, including show real-time data, freeze frame data, I/M Readiness, DTC lookup, test results for o-xygen sensor, On-board monitor test, request vehicle information, component test, modules present and e-vap test. Allowing you to quickly identify and troubleshoot vehicle issues.